Washing machine washing control method and washing machine

A laundry control and washing machine technology, which is applied to the control device of washing machine, other washing machines, washing devices, etc., can solve the problem that it is difficult to achieve hot water washing powder or hot water washing, washing efficiency, low washing ratio, and ordinary pulsator washing machines. There are no problems such as installing heating devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

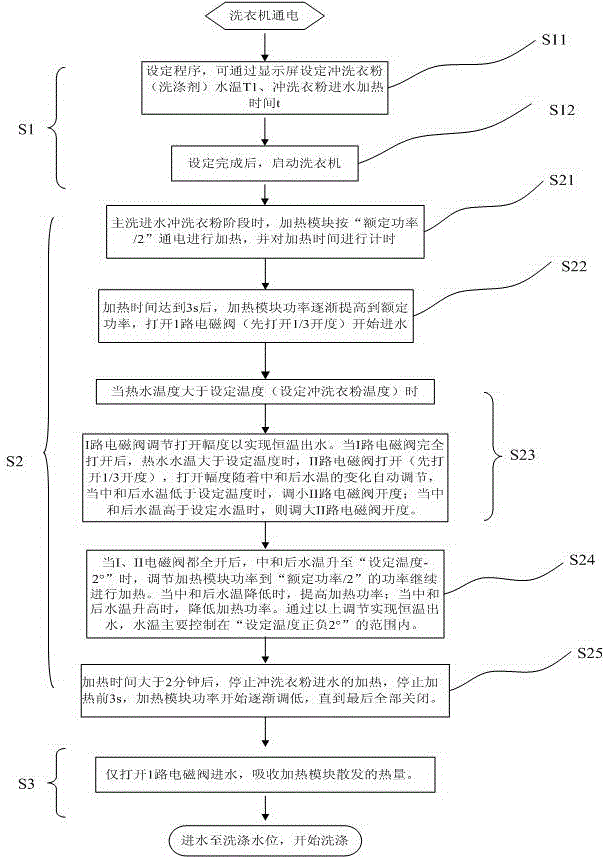

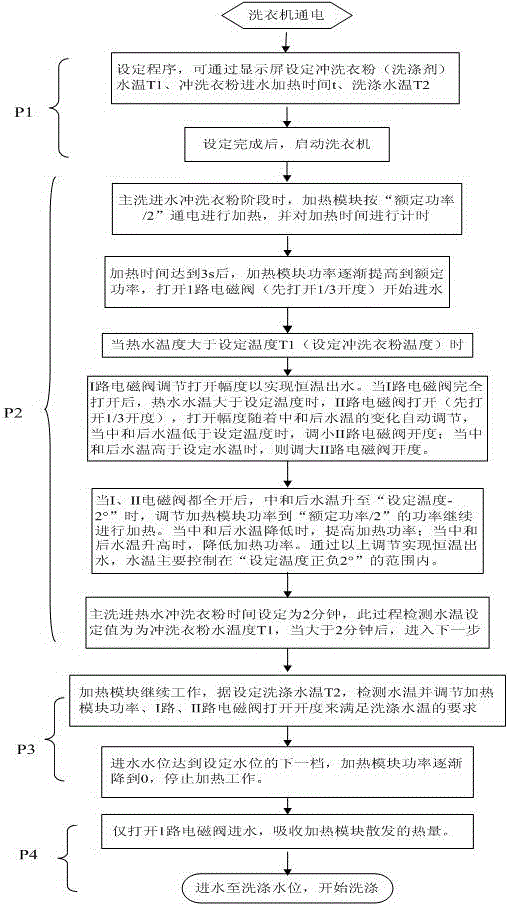

[0022] The washing control method of the washing machine provided by the present invention will be described in detail below in conjunction with the attached flow chart.

[0023] see figure 1 Shown is the first embodiment of the present invention. After the washing machine is powered on, the user can set the water temperature T1 for washing powdered clothes or detergent through the display screen, and the warm-up time t of the heating module for washing powdered clothes into the water.

[0024] After the washing machine is started, when the washing machine enters the stage of rinsing clothes powder with water, it first energizes the heating module to heat according to the power of "rated power / 2", and gradually increases the power of the heating module to the rated power after 3 seconds, and at the same time turns on the I electromagnetic Valve, first open 1 / 3 of the opening, the water starts to heat up, with the heating, the water temperature gradually rises, when the hot wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com