Noise-eliminating device for valve spring in valve actuating mechanism of engine

A valve train, valve spring technology, applied in the direction of engine components, machines/engines, valve devices, etc., can solve the problems of harsh, difficult, and easy to cover up spring sound, and achieves elimination of chatter noise, low cost, and elimination of bad noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

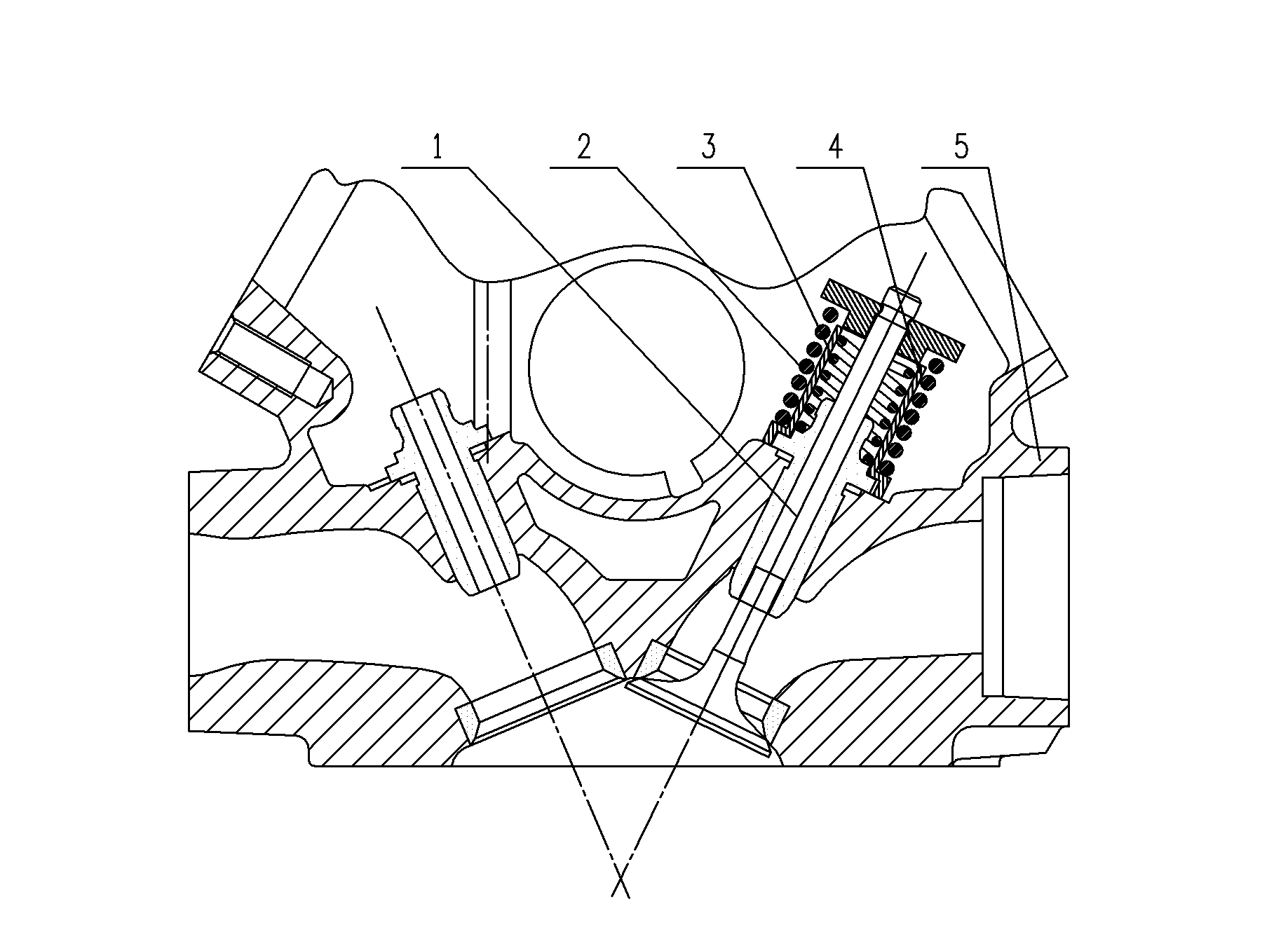

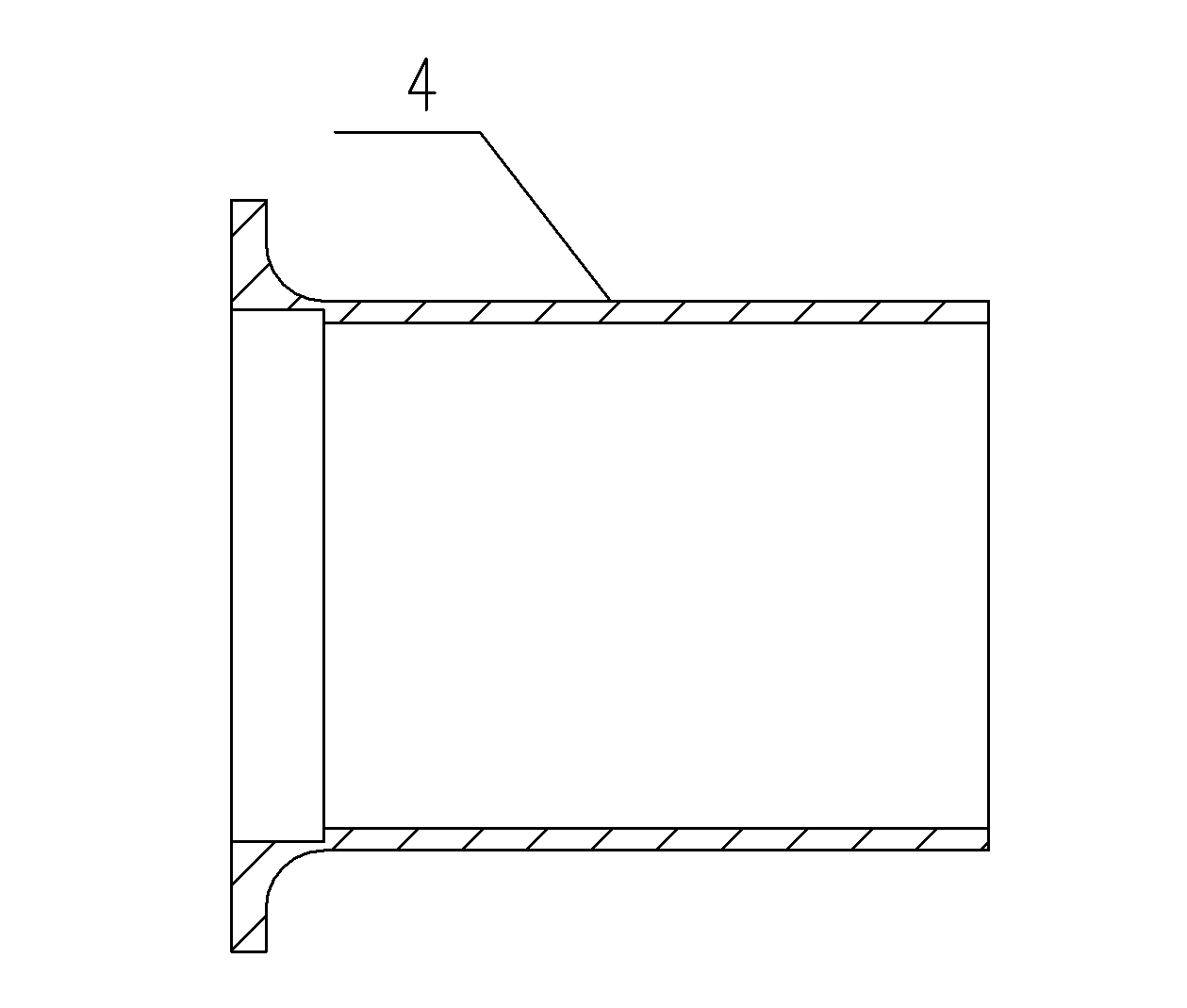

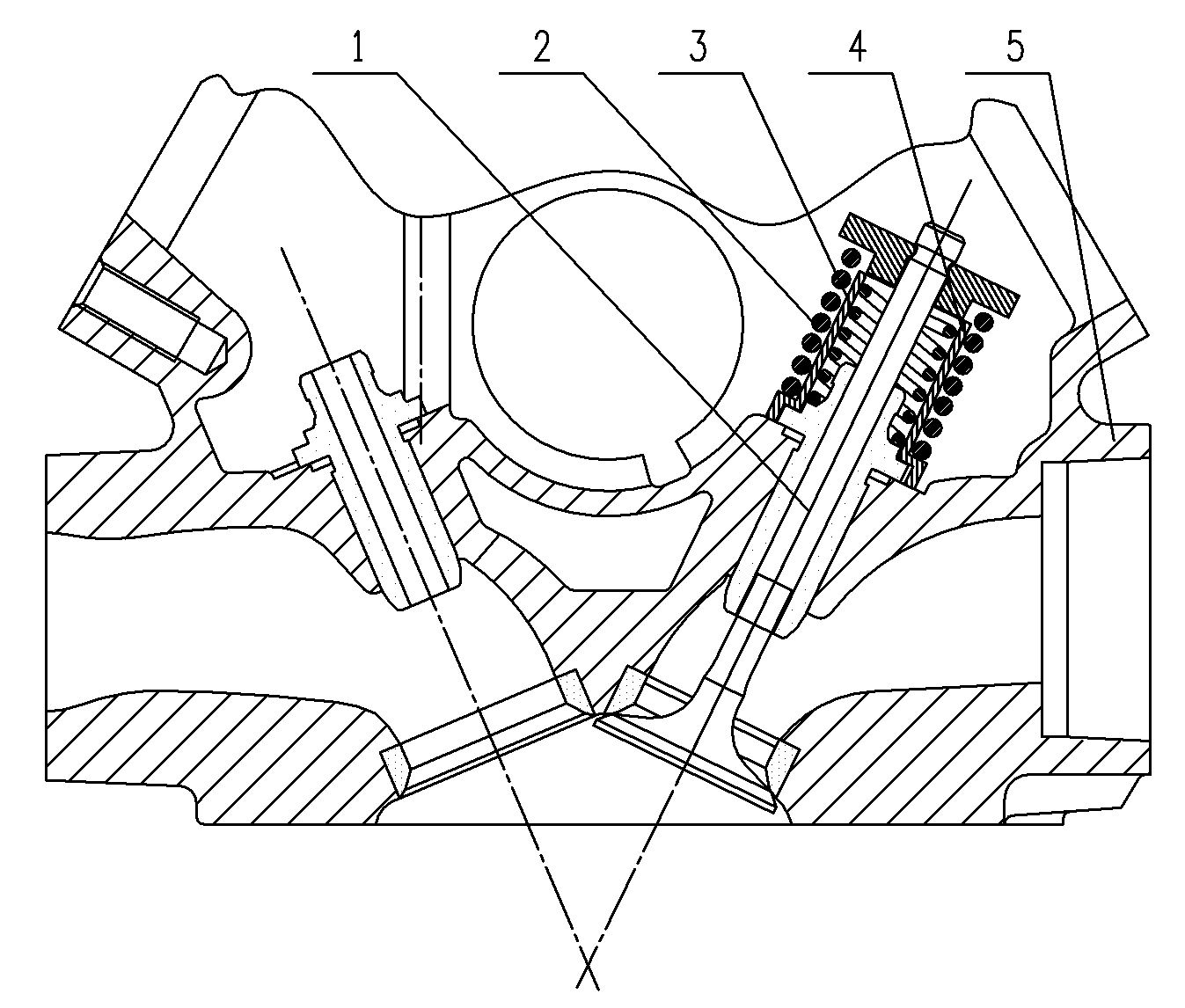

[0012] Such as figure 1 and figure 2 As shown, the valve spring noise elimination device in the engine gas distribution mechanism of the present invention includes a cylinder head 5, a valve 1 and a spring, and a step bush 4 is provided between the valve 1 and the spring, and the step bush 4 and the spring are clearance fit . The step bushing 4 is a step bush made of nylon or a step bush made of polytetrafluoroethylene. The stepped bushing 4 made of the above materials has self-lubricating properties, can fundamentally eliminate friction noise, and has excellent anti-fatigue effect. The present invention does not change the original engine valve 1, but only adds a step bush 4 between the spring and the valve 1, and the step bush 4 and the valve spring are in clearance fit, which can effectively eliminate noise.

[0013] In this embodiment, the valve spring is an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com