A rolling rotor two-stage compressor

A two-stage compressor and rolling rotor technology, which is applied in the field of compressors, can solve the problems of reduced reliability of compressors, chattering of check valve cores, and pressure fluctuations, so as to improve reliability, prevent liquid entrainment, and reduce The effect of pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

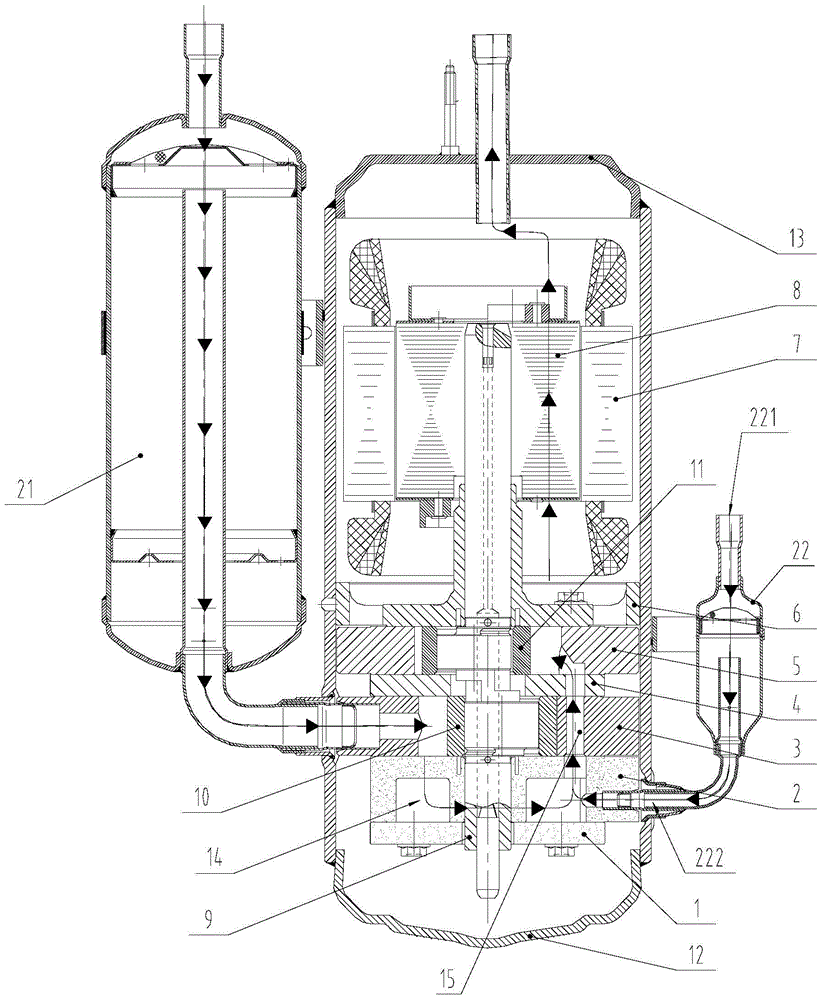

[0033] Aiming at the problem of vibration and noise of the one-way valve of the air supply pipeline in the prior art, and the problem of liquid in the high-pressure stage suction, the present invention finds through research and tests that by reasonably setting the displacement of the first-stage cylinder and the volume of the relevant chamber, The aforementioned problems can be alleviated or eliminated.

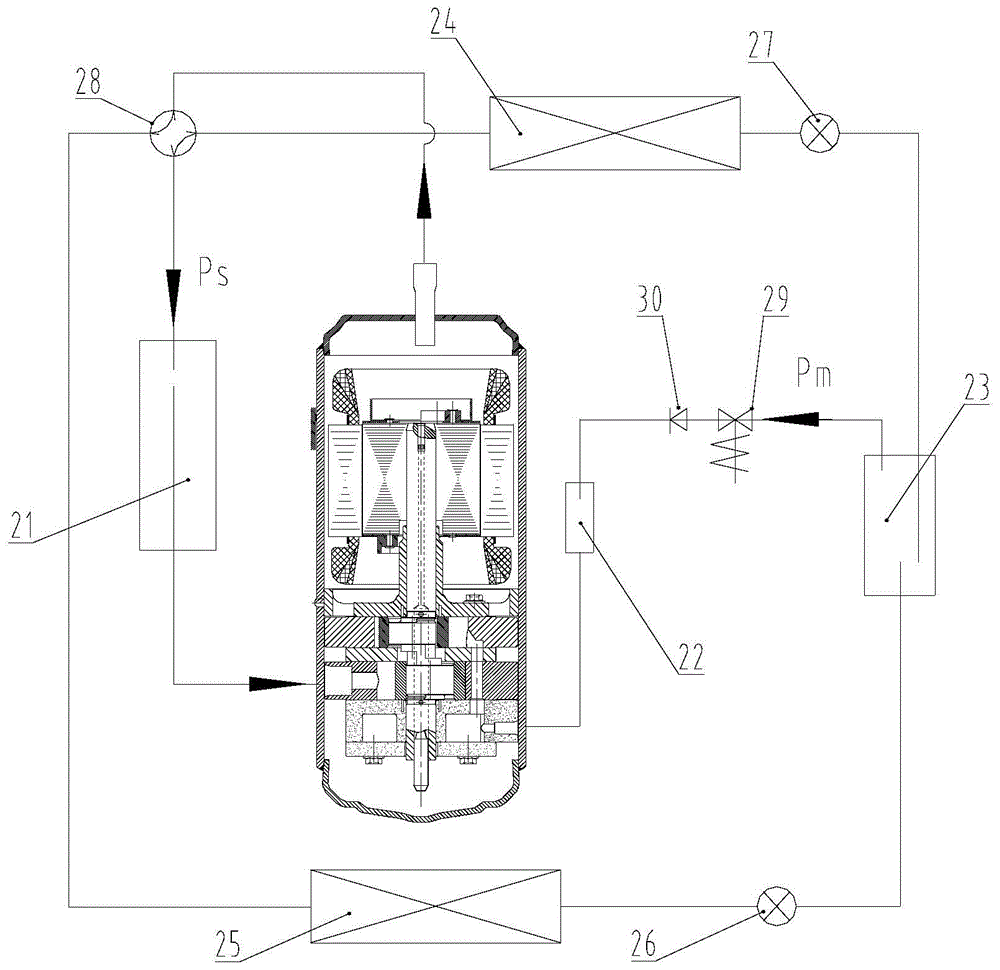

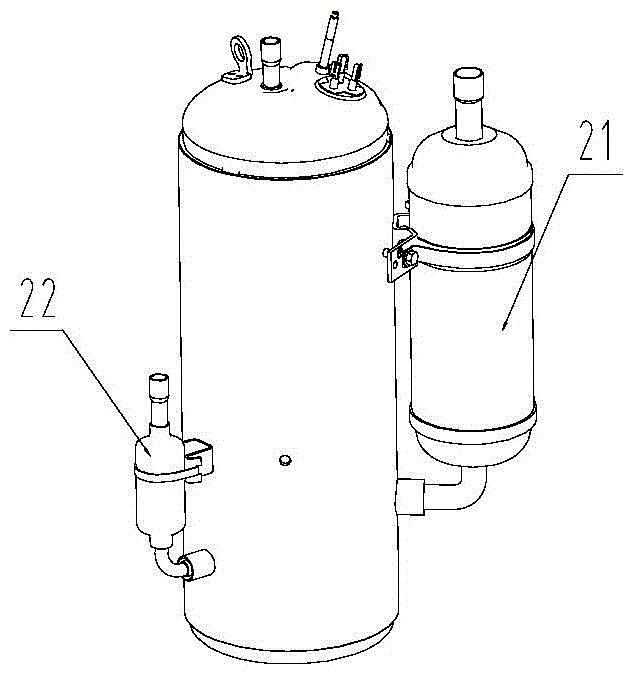

[0034] To this end, the present invention provides a two-stage rolling rotor compressor. Typically, the two-stage compressor includes a first-stage cylinder, a first-stage exhaust cavity, an enthalpy-increasing component, and a second-stage cylinder, wherein the first The first-stage exhaust cavity communicates with the exhaust port of the first-stage cylinder, and communicates with the suction port of the second-stage cylinder and the outlet of the enthalpy-increasing component through an intermediate flow channel.

[0035] For this type of two-stage compressor, the displac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com