Test machine for capacitive touch screen system

A capacitive touch screen, system testing technology, applied in the direction of electrical digital data processing, instruments, data processing input/output process, etc., can solve the problem that the capacitive touch screen cannot be satisfied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

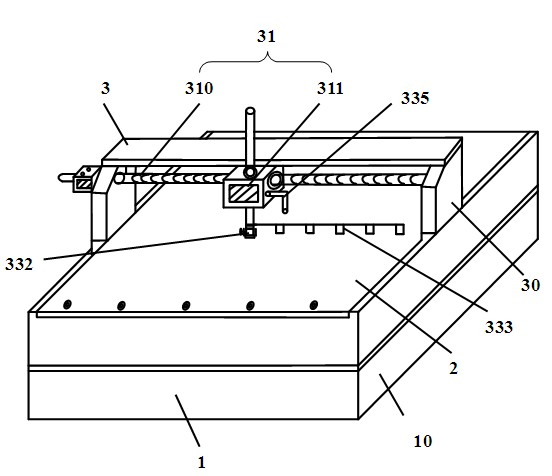

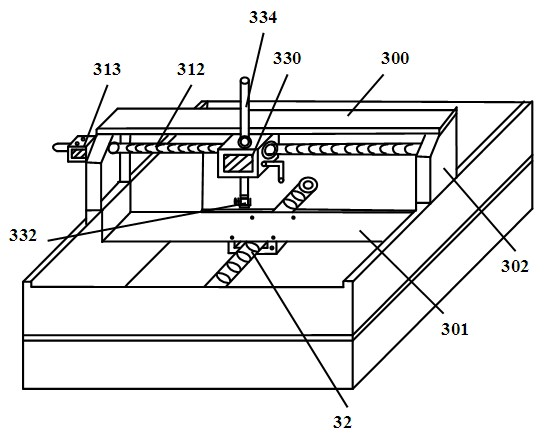

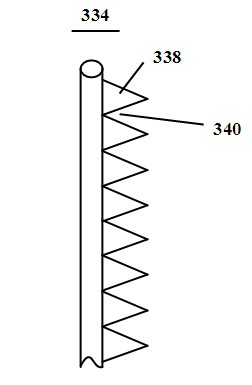

[0014] Please also refer to figure 1 and figure 2 The capacitive touch screen system testing machine of the present invention includes a housing 1, a cover body 2 that covers and buckles the housing 1, and a moving mechanism 3 erected on the housing 1. The housing 1 includes opposite side walls 10, so The side wall 10 is provided with a slide groove (not labeled). The moving mechanism 3 includes a supporting frame 30 erected on the housing, a bidirectional moving mechanism 31 and a one-way moving mechanism 32. The supporting frame 30 includes opposite upper and lower base plates 300, 301 and vertically connecting the upper and lower base plates 300, 301 and side base plates 302 opposite to each other, the side base plates 302 partly protrude into the slide groove, so that the support frame 30 can slide relative to the housing 1 .

[0015] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com