Short circuit preventing socket and electric connector

An electrical connector, anti-short-circuit technology, applied in the direction of connection, two-part connecting device, and components of the connecting device, etc., can solve the problems that the front layer does not have anti-short-circuit, self-locking, and anti-short-circuit functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

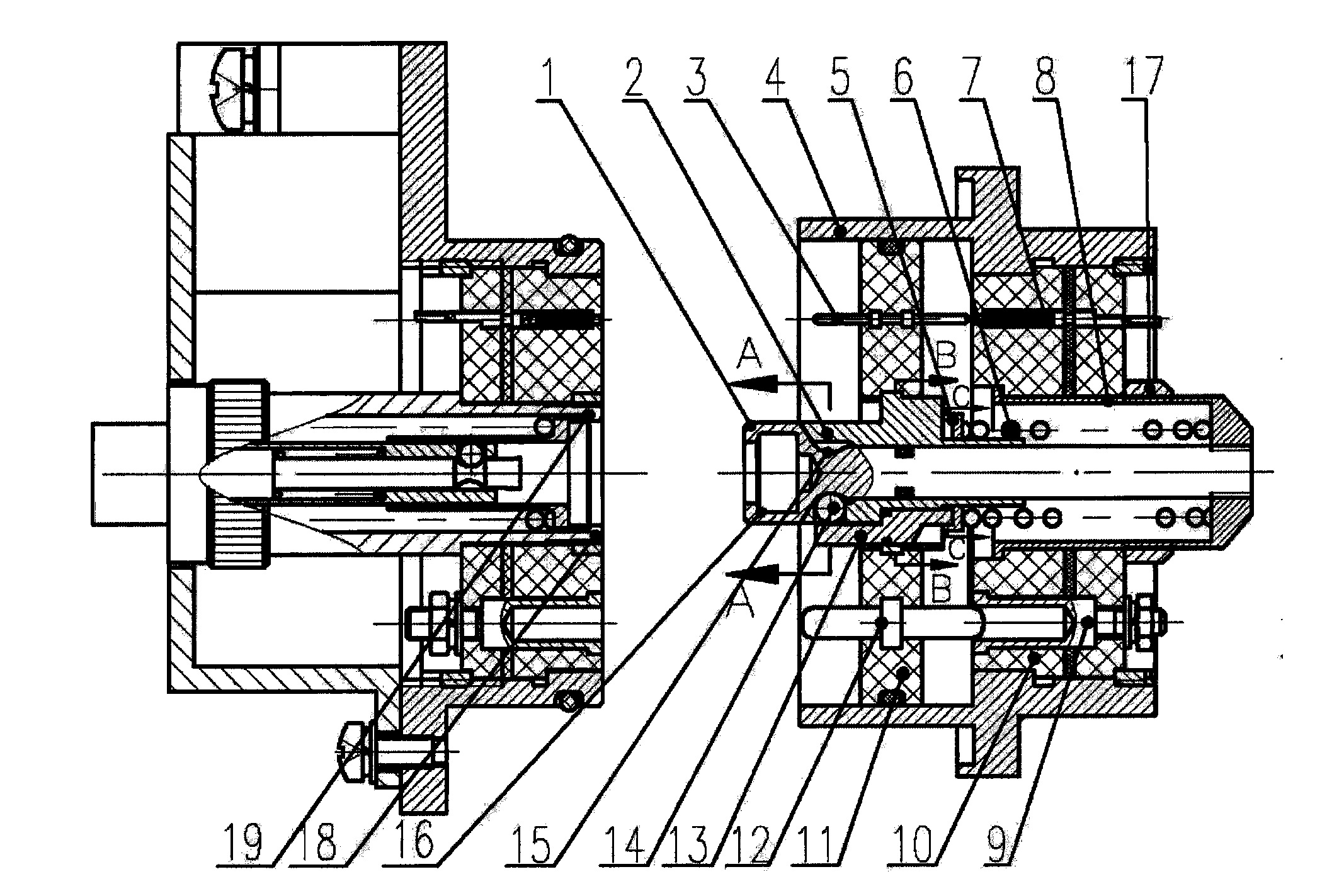

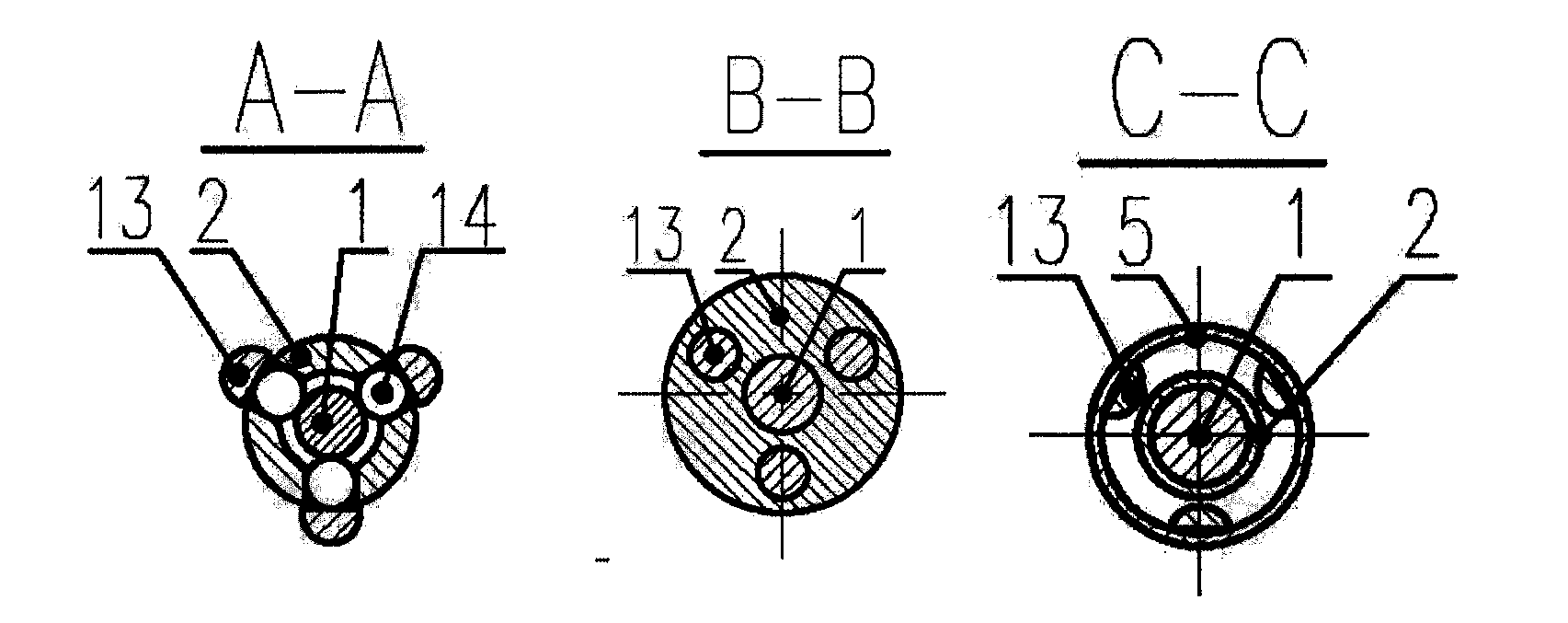

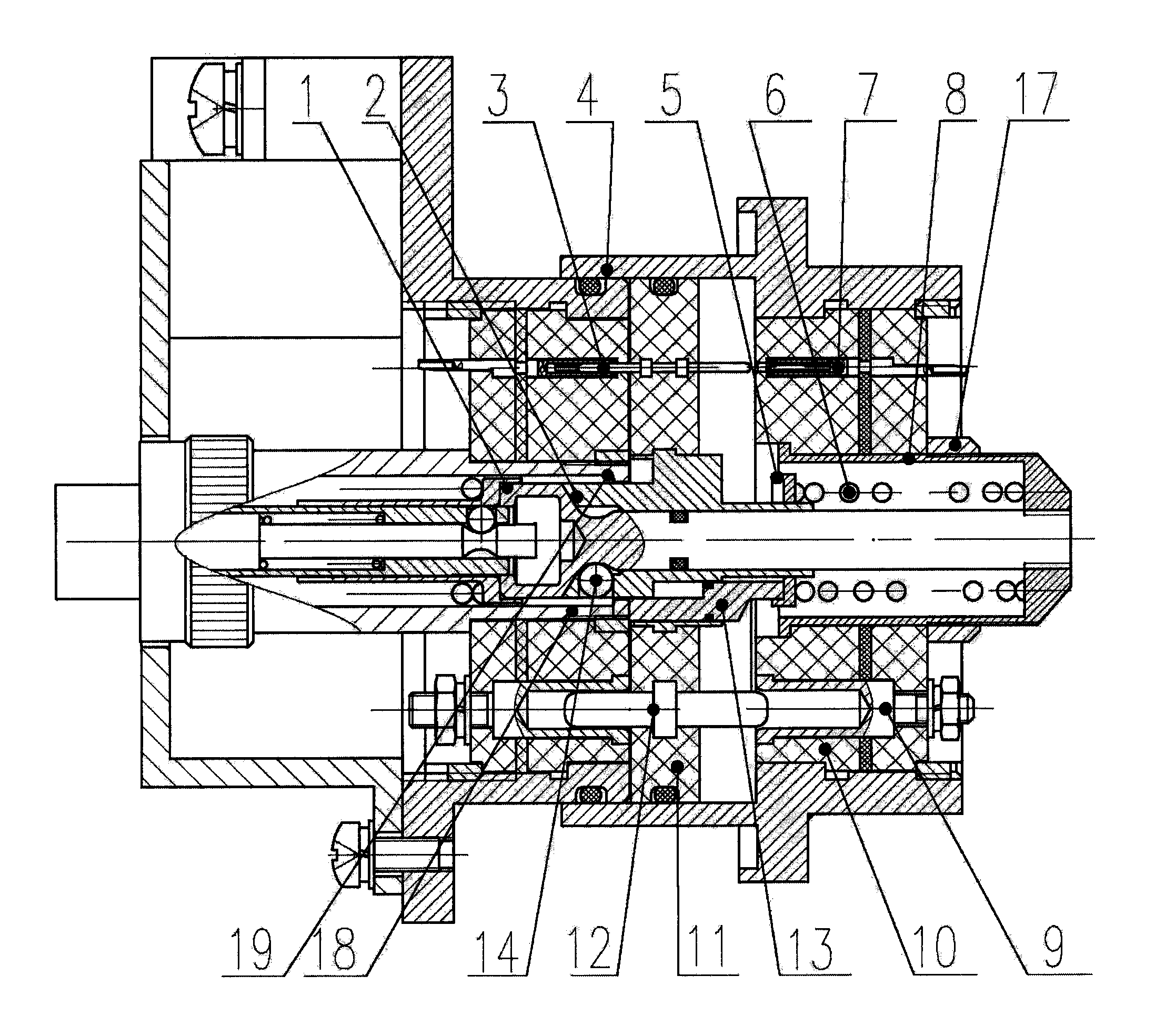

[0023] Such as figure 1 As shown, the anti-short circuit socket includes a front layer 11, a back layer 10 and a housing 4, and the front layer and the back layer are located in the housing; the socket also includes a locking mechanism, and the locking mechanism is provided with There is a locking rod 1, and the outer surface of the locking rod is provided with an outer circular groove 15, and the groove 15 cooperates with the steel ball 14 to realize the locking of the front layer of the socket. The first steel ball 14 is fixedly installed in the hole of the positioning sleeve 2 and can move radially. The locking rod 1 is fixed on the spring seat 8 by threads. The spring seat 8 is fixed on the socket back layer 10 by the parallel nut 17, and the socket back layer 10 is fixed in the socket housing 4, so that the locking rod 1 is fixed inside the socket. Three special-shaped locking blocks 13 are installed in the retaining ring 5, forming a three-claw shape. The special-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com