Low-dew-point gas generator

A technology of gas generating device and gas generator, which is applied in the direction of gas generating device, chemical instrument and method, chemical/physical process, etc., and can solve the problem of high dew point temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

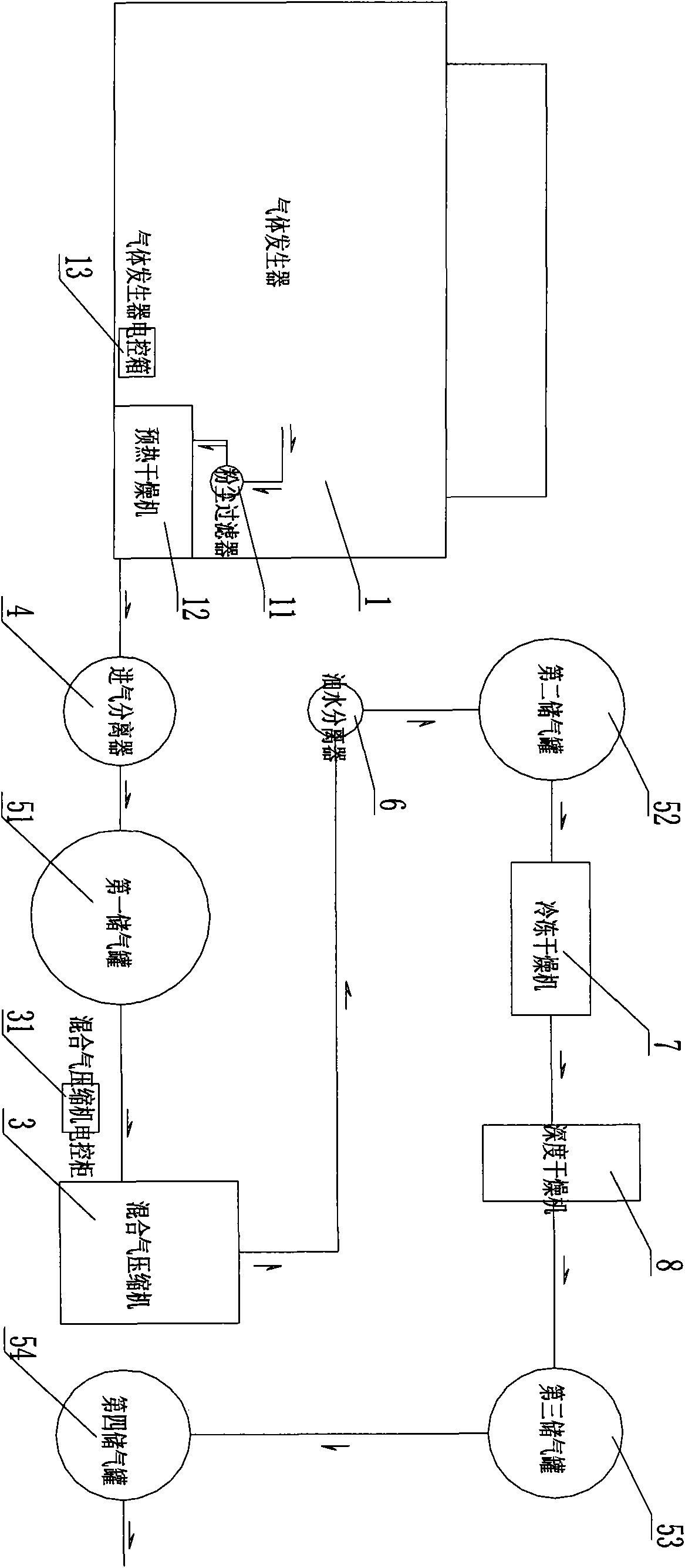

Embodiment 1

[0018] In Embodiment 1, the connecting portion of the gas generator 1 and the inlet separator 4 further includes a dust filter 11 connected to the gas generator 1 , and the dust filter 11 connected to a preheating dryer 12 . The dust filter 11 is used for preliminary impurity removal of the mixed gas generated in the gas generator 1, and the mixed gas from which the impurities are removed enters the preheating dryer 12, and the mixed gas is preheated by the preheating dryer 12 and its content is removed. of water vapor.

Embodiment 2

[0019] In the second embodiment, the connection between the freeze dryer 7 and the third gas tank 53 also includes a deep dryer 8, the freeze dryer 7 is connected to the deep dryer 8, and the deep dryer 8 is connected to the third gas tank 53 . The mixed gas output by the freeze dryer 7 can pass through the deep dryer 8 to further reduce the dew point of the gas.

Embodiment 3

[0020] In the third embodiment, the third gas storage tank 53 is connected with a fourth gas storage tank 54 . Since the gas pressure generated by the third gas storage tank 83 is relatively high and the dew point temperature is lowered, the gas output from the third gas storage tank 53 is buffered by the fourth gas storage tank 54 to facilitate gas extraction from the fourth gas storage tank 54 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com