Tapered sheet metal component drawing method

A conical and sheet metal technology, applied in the field of material processing engineering plastic forming, can solve problems such as unqualified parts, double transfer marks, and bulging of the profile, so as to avoid slippage at the transfer point, and the operation method is simple and reliable , the effect of high profile precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

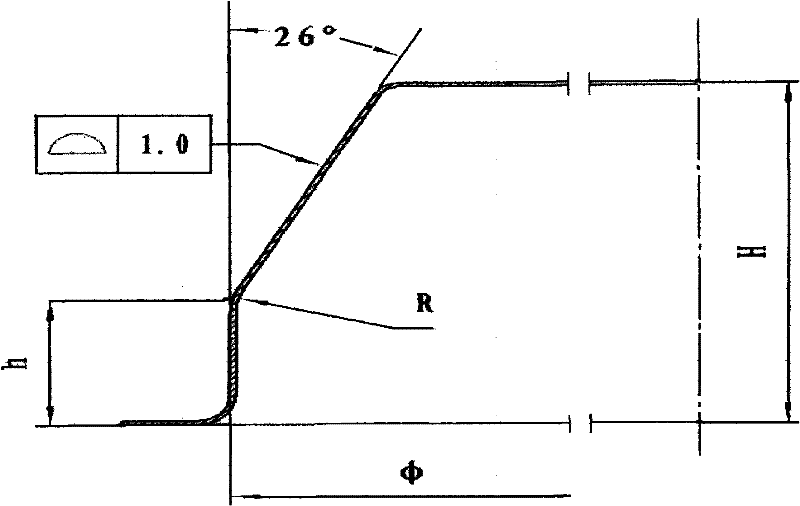

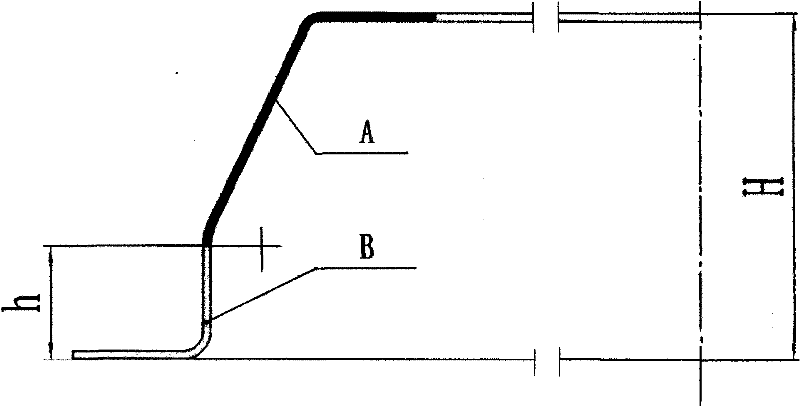

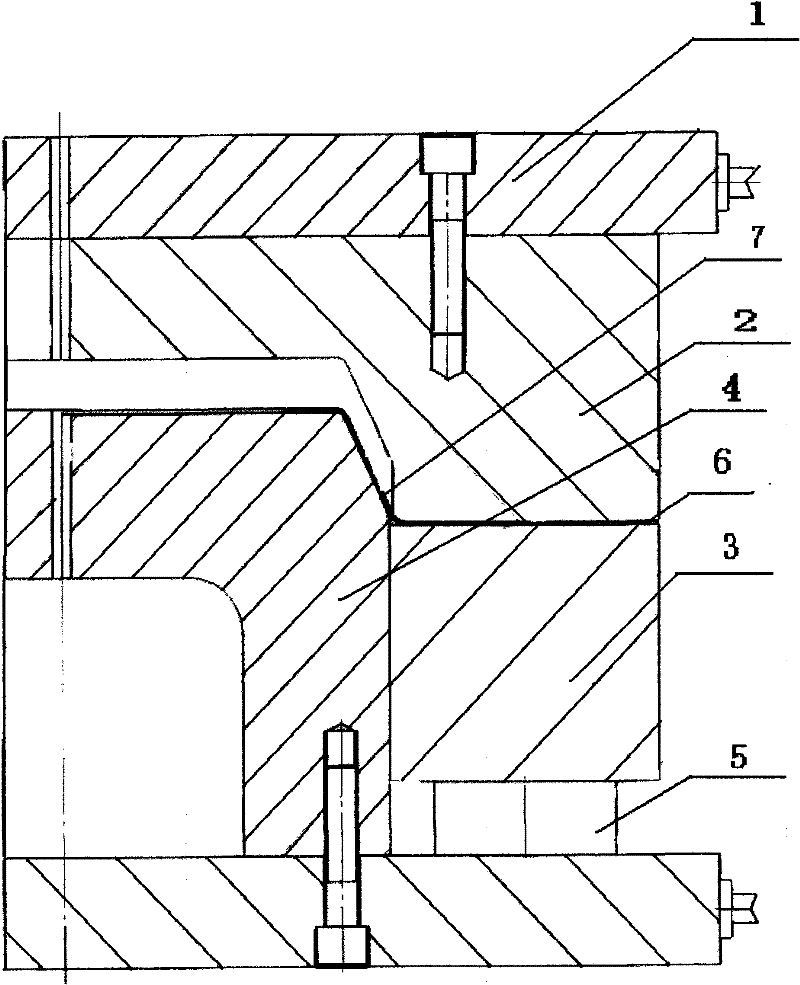

Embodiment 1

[0017] The material of the part to be formed is GH3044, and the thickness of the material is 1.0mm. The structure and parameter requirements of the part are as follows figure 1 As shown, a drawing die with a blank holder device is made by conventional means according to the size standard of the part for deep drawing. The whole drawing process is divided into two steps: first, "conical" deep drawing, and the part at A For the flanging forming part, the material is fed from the inner hole; then, the "straight wall" is drawn, and the drawn forming part at B in the part is fed from the outer edge; where the overall drawing height of the part is H, The drawing height at B is h (see figure 2 ), the specific deep drawing process, such as image 3 As shown: First, a concentric circle of wool is developed according to the principle of equal area, and the unfolded wool is placed on the blank holder 3 of the drawing die, and then the movable limit block 5 is placed on the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com