Tapered sheet metal component drawing method

A conical, sheet metal technology, applied in the field of material processing engineering plastic forming, can solve the problems of unqualified, bulging, double transfer trace parts profile, etc. , The operation method is simple and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

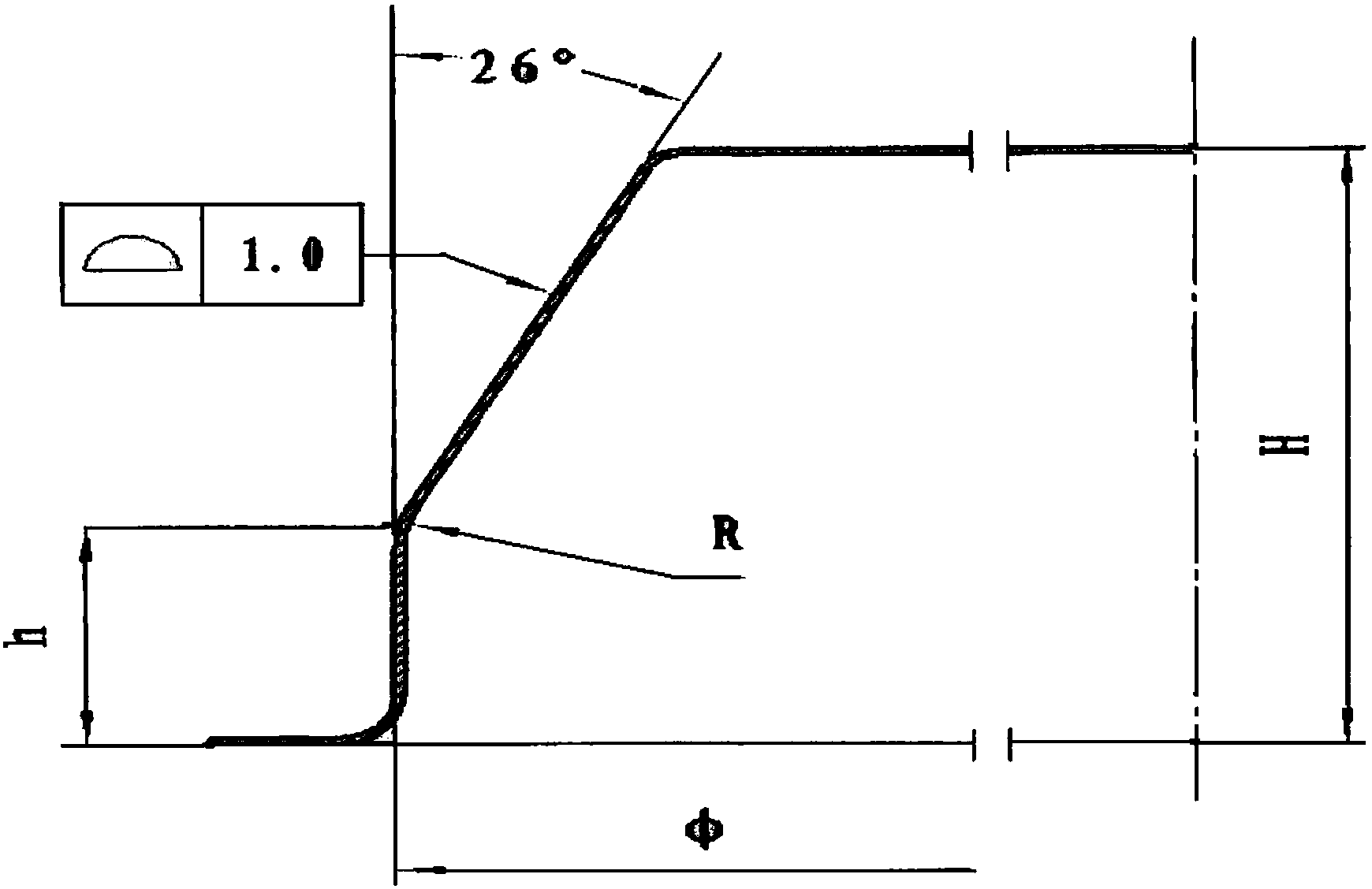

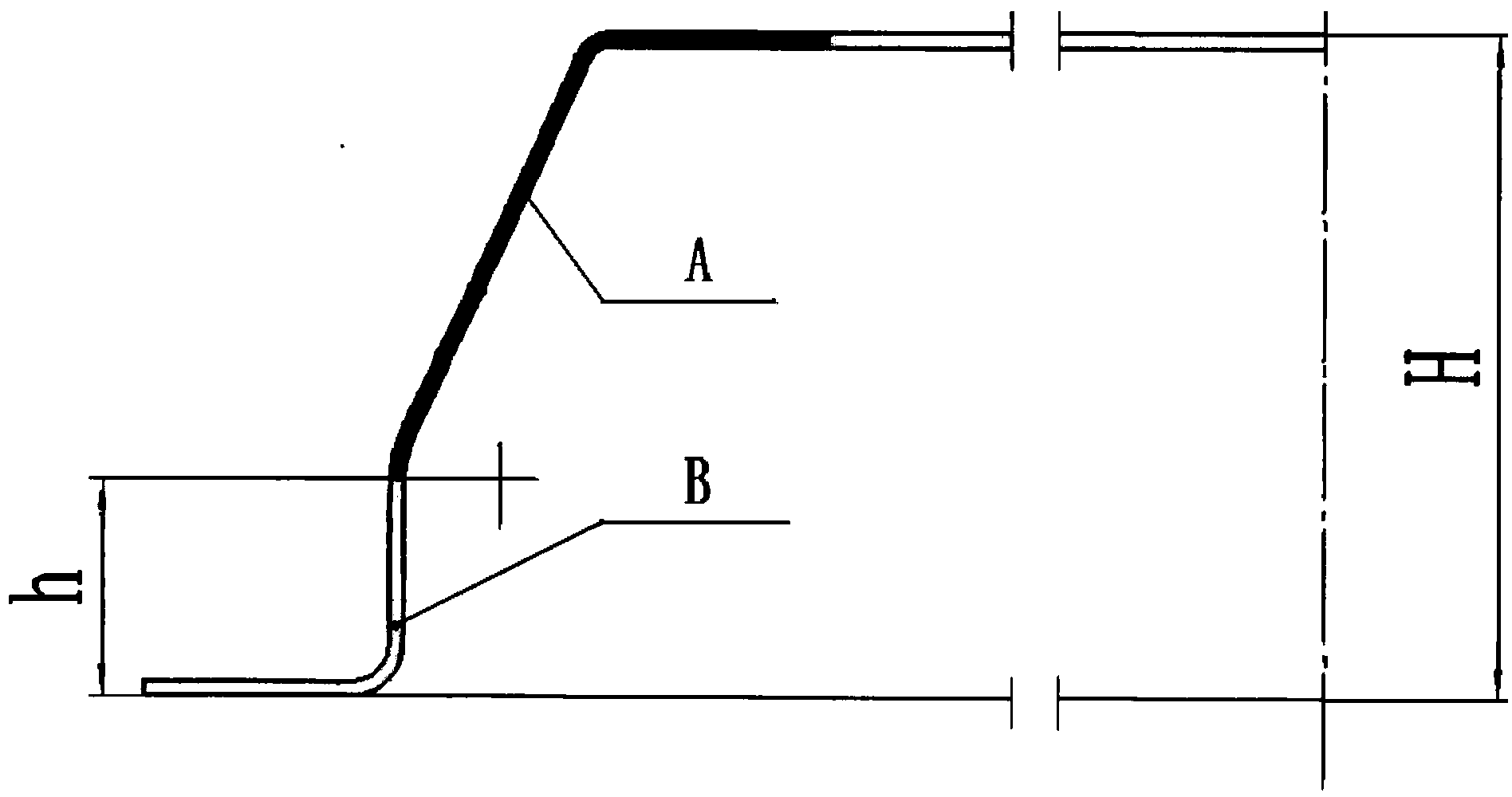

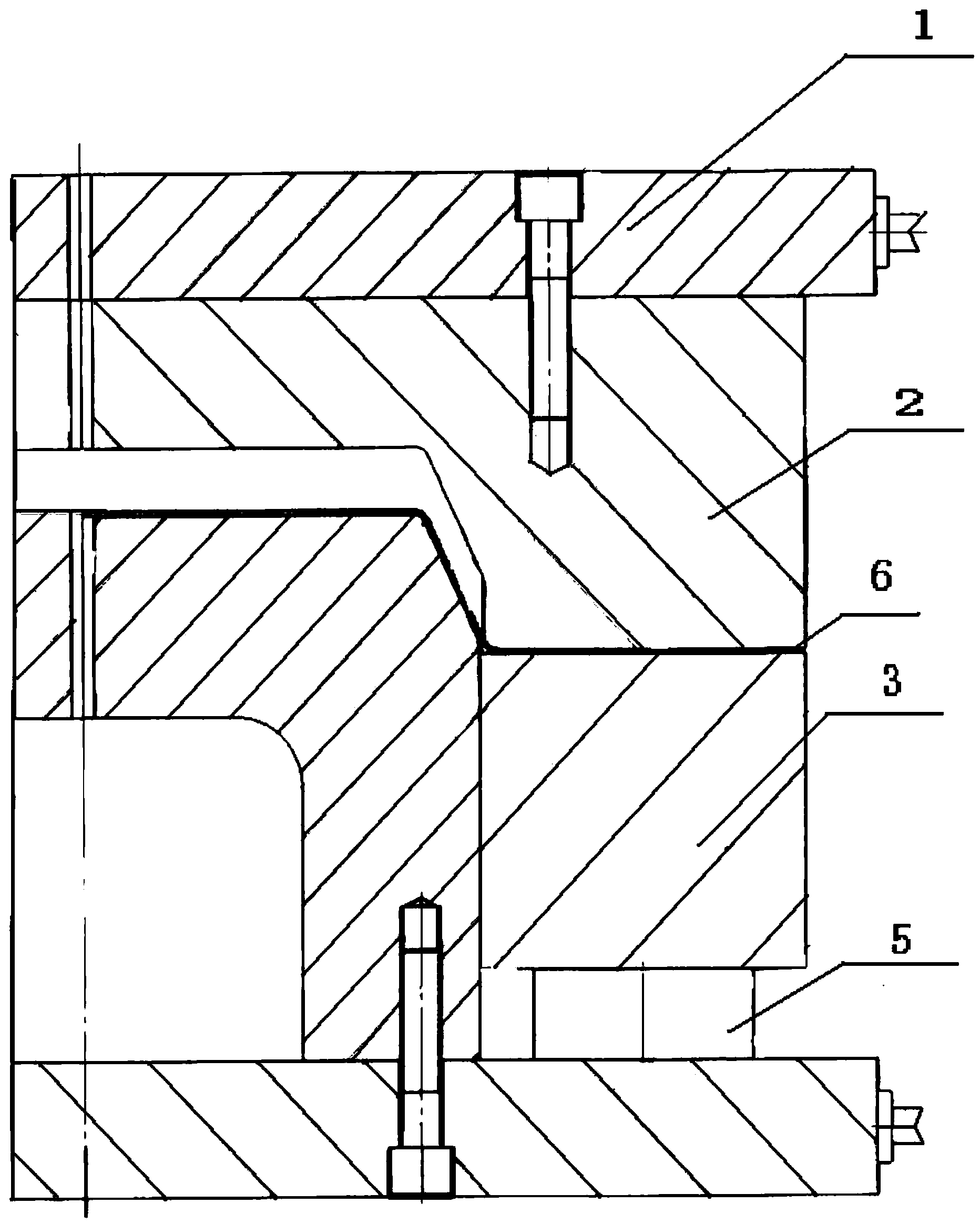

Embodiment 1

[0017] The material of the part to be formed is GH3044, and the thickness of the material is 1.0mm. The structure and parameter requirements of the part are as follows figure 1 As shown, a drawing die with a blank holder device is made by conventional means according to the size standard of the part for deep drawing. The whole drawing process is divided into two steps: first, "conical" deep drawing, and the part at A For the flanging forming part, the material is fed from the inner hole; then, the "straight wall" is drawn, and the drawn forming part at B in the part is fed from the outer edge; where the overall drawing height of the part is H, The drawing height at B is h (see figure 2 ), the specific deep drawing process, such as image 3 As shown: First, a concentric circle of wool is developed according to the principle of equal area, and the unfolded wool is placed on the blank holder 3 of the drawing die, and then the movable limit block 5 is placed on the bottom of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com