Grinding wheel reinforced mesh pick-up method

A technology for enhancing nets and grinding wheels, which is applied in the direction of object supply, sending objects, stacking receiving devices, etc., can solve the problems of high labor intensity, low efficiency, and inability to pick up in a row, so as to improve work efficiency, quickly and neatly organize, reduce The effect of labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

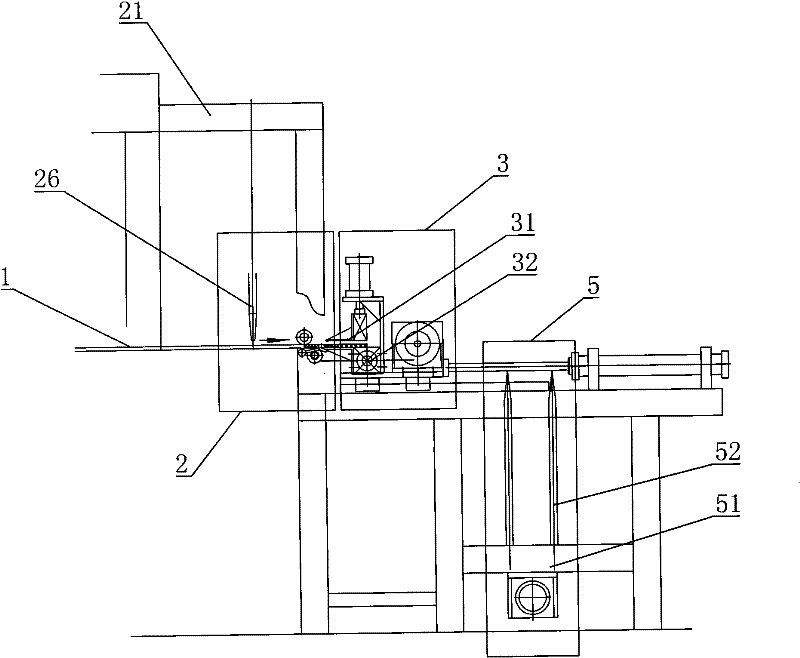

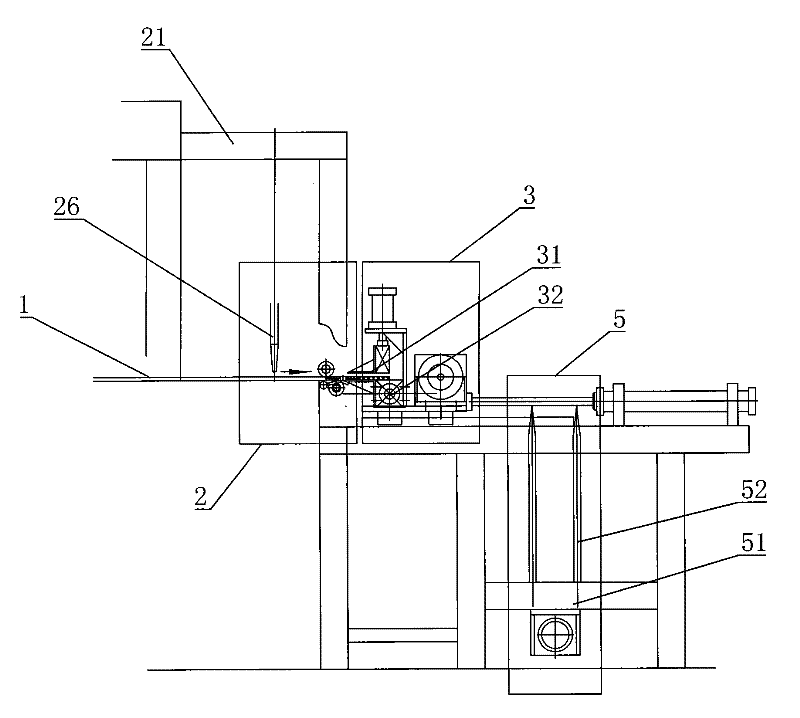

[0011] For realizing the method of the present invention, manufactured the pick-up device of following structure: as figure 1 As shown, the pick-up device uses the conveyor belt 1 as the mesh conveying carrier, and the upper and lower wax paper adsorption areas 2 are arranged on the side of the conveyor belt 1, and the waste edge stamping area 3 is provided at the front end of the conveyor belt, and the waste edge stamping area 3 The end is provided with finishing device area 5.

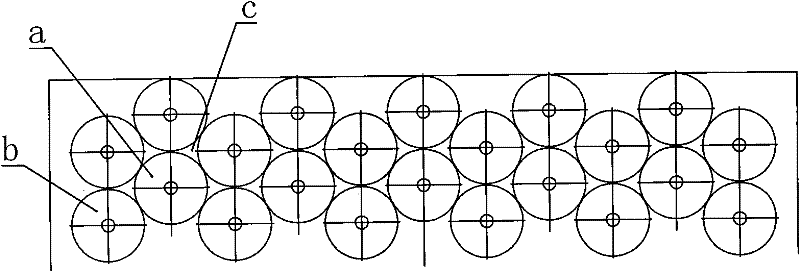

[0012] After the entire mesh cloth completes the molding process of the mesh, it moves forward as a whole on the conveyor belt 1, and the arrangement of the formed mesh on the entire mesh cloth is (this arrangement is actually the mesh on the conveyor belt). arrangement): such as figure 2 As shown, the meshes are arranged in several rows on the conveyor belt 1, the front row a and the rear row b are staggered, and the mesh gap between the front row a and the rear row b is the size of the waste edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com