Contact system used for double-breakpoint plastic casing breaker

A molded case circuit breaker and contact system technology, which is applied in the direction of circuit breaker contacts, circuit breaker components, etc., can solve problems such as fallback, high energy, and arc re-ignition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

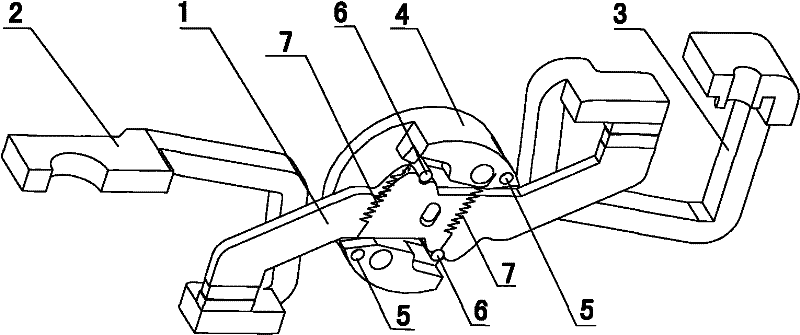

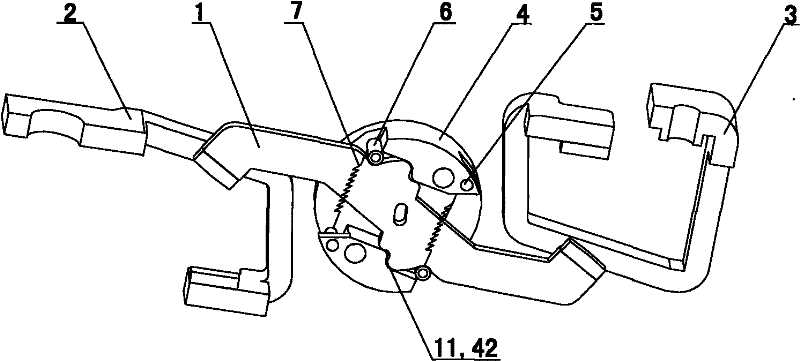

[0020] see figure 1 , figure 2 , the present invention is used for the contact system of the plastic case circuit breaker with double breaking points, including the moving contact 1, the first static contact 2, the second static contact 3 and the rotating shaft 4, as well as two fixed shaft pins 5, two sliding shaft pins 6 and two springs 7. The shaft is functionally connected to the circuit breaker operating mechanism.

[0021] Cooperate see Figure 4 , Figure 5 , the rotating shaft 4 in the present invention is provided with a radially penetrating slotted hole 41 , and two concave arc-shaped steps 42 are symmetrically provided in the slotted hole 41 .

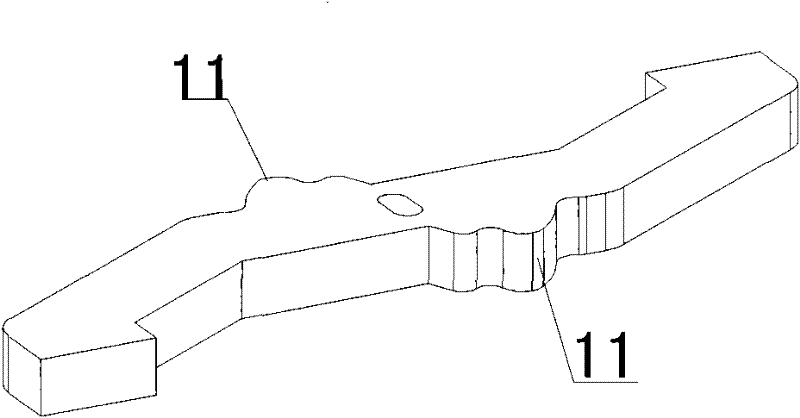

[0022] Cooperate see image 3 , the moving contact 1 in the present invention is installed in the rotating shaft 4 through the slotted hole 41 of the rotating shaft 4, and the two sides of the moving contact 1 are symmetrically provided with two convex arc-shaped sliding surfaces 11, and the two concaves in the slotted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com