Vibrating screen ore-feeding device

A vibrating screen and ore feeding technology, applied in the direction of screen, solid separation, grid, etc., can solve the problems of uneven load, large fluctuation of ore output, large machine vibration, etc., to improve efficiency and operation rate, and reduce machine failure. , Effective use of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

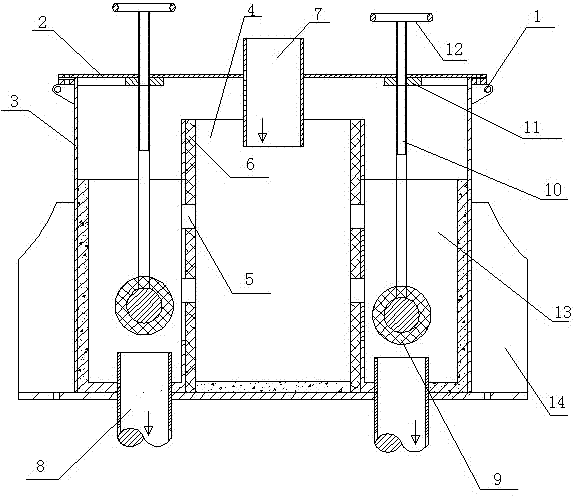

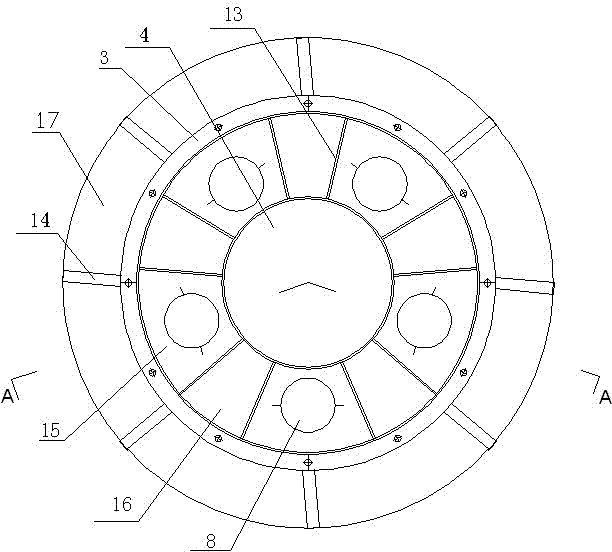

[0028] Such as figure 1 , 2 As shown, there are five vibrating screen feeding devices in the mining area, including a fully enclosed cylindrical box 3, a sealing cover 2 above the box 3, and a triangular lifting hole 1 on both sides of the sealing cover 2, and the sealing cover 2 The central part is provided with a splash-proof sealing door and an ore feeding pipe 7; a central cylinder 4 for buffering ore slurry is provided in the middle of the box body 3, and an ore outlet hole 5 is provided on the side wall of the central cylinder 4; ten blocks are arranged outside the central cylinder 4 The ore separation plate 13 divides the casing into five ore separation areas 16 and five ore output areas 15, each ore output area 15 below is provided with an ore output pipe 8, and the outer end outlet of the ore output pipe 8 is set to a fan shape; 8 is provided with a wear-resistant composite ore feeding ball valve 9, and the top of the ore ball valve 9 is connected with an adjusting s...

Embodiment 2

[0042] Vibrating screen feeding device with six mining areas:

[0043] Around the bottom of the cylinder body of the ore feeding device, a total of 12 ore separation plates are used to divide it into six ore discharge areas and six ore separation areas. The feature is that in order to ensure uniform ore discharge, the corresponding center angle of the ore discharge area is 40°, and the shape of the fan-shaped separation area Inner diameter / outer diameter × sector angle = (Φ450~Φ600) / (Φ800~Φ1500) mm×20°, the purpose is to ensure uniform ore discharge around the ore feeding device and strengthen the strength between the central cylinder and the ore feeding device cylinder ; The mine pipe is designed at the bottom of each mining area. All the other parts are the same as in Embodiment 1.

Embodiment 3

[0045] Vibrating screen feeding device with eight mining areas:

[0046] A total of 16 ore separation plates are used around the bottom of the cylinder of the ore feeding device to divide it into eight mining areas and eight separation areas. The feature is that in order to ensure uniform ore extraction, the corresponding center angle of the ore output area is 30°, and the shape of the fan-shaped separation area Inner diameter / outer diameter × sector angle = (Φ450~Φ600) / (Φ800~Φ1500) mm×15°, the purpose of which is to ensure uniform ore discharge around the ore feeding device and strengthen the strength between the central cylinder and the ore feeding device cylinder ; The mine pipe is designed at the bottom of each mining area. All the other parts are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Dimensions | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com