Structure of novel hole-piercing punch

A punch punch, a new type of technology, applied in the field of stamping dies, can solve the problems of not sharp enough blade, large investment, high production cost, etc., and achieve the effect of low investment production cost and small stamping production

Inactive Publication Date: 2012-05-16

王后平

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, in the structure of the punching die, the punching die is generally composed of a handle and a punch. The working surface of the punch, that is, the shearing surface, is a planar structure. Although this structure has a simple structure , has the advantages of better manufacturability and higher strength, but due to structural reasons, its blade is not sharp enough. In order to punch larger holes or thicker sheets, a larger press must be used. Large investment in stamping production, high production cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

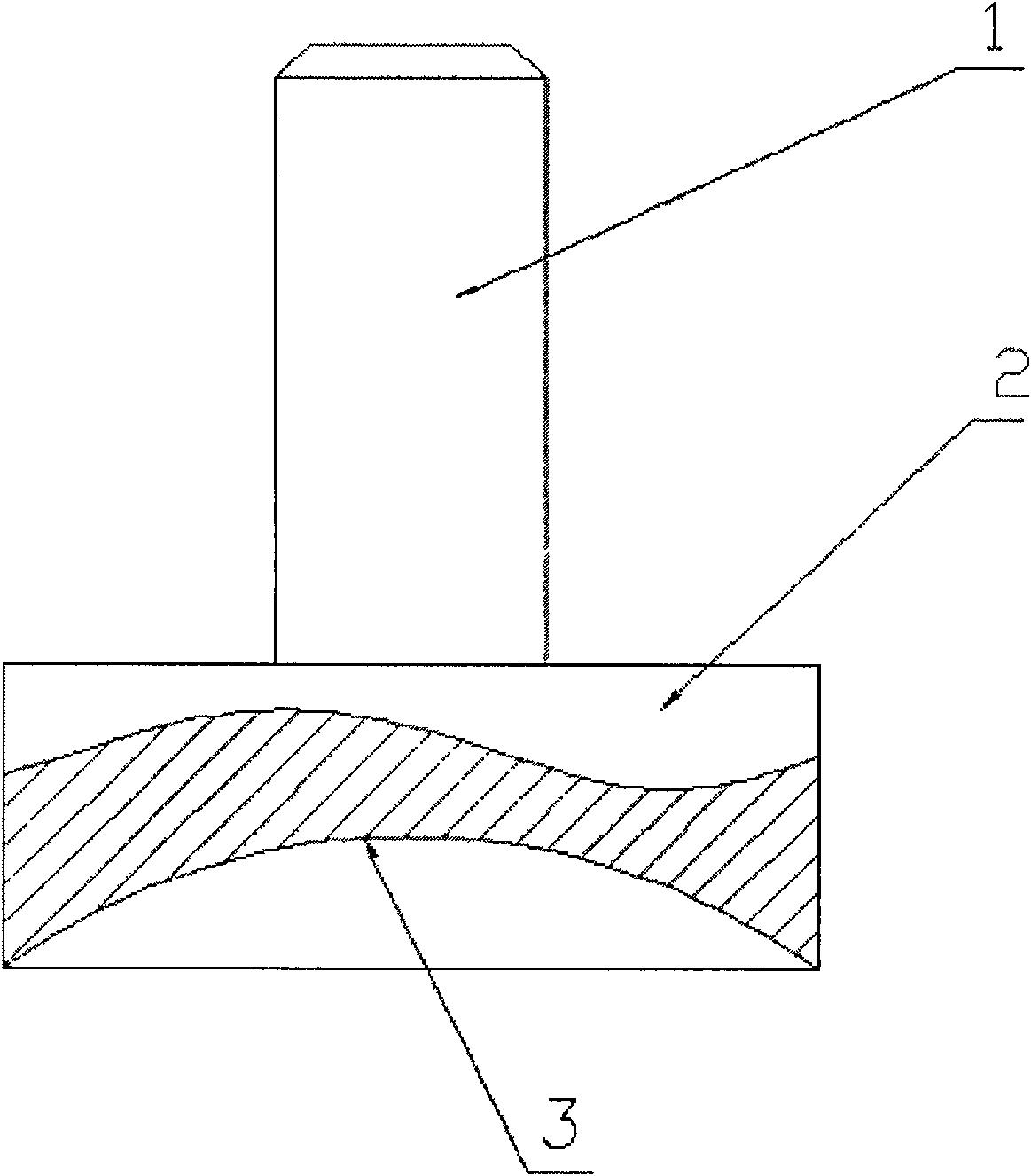

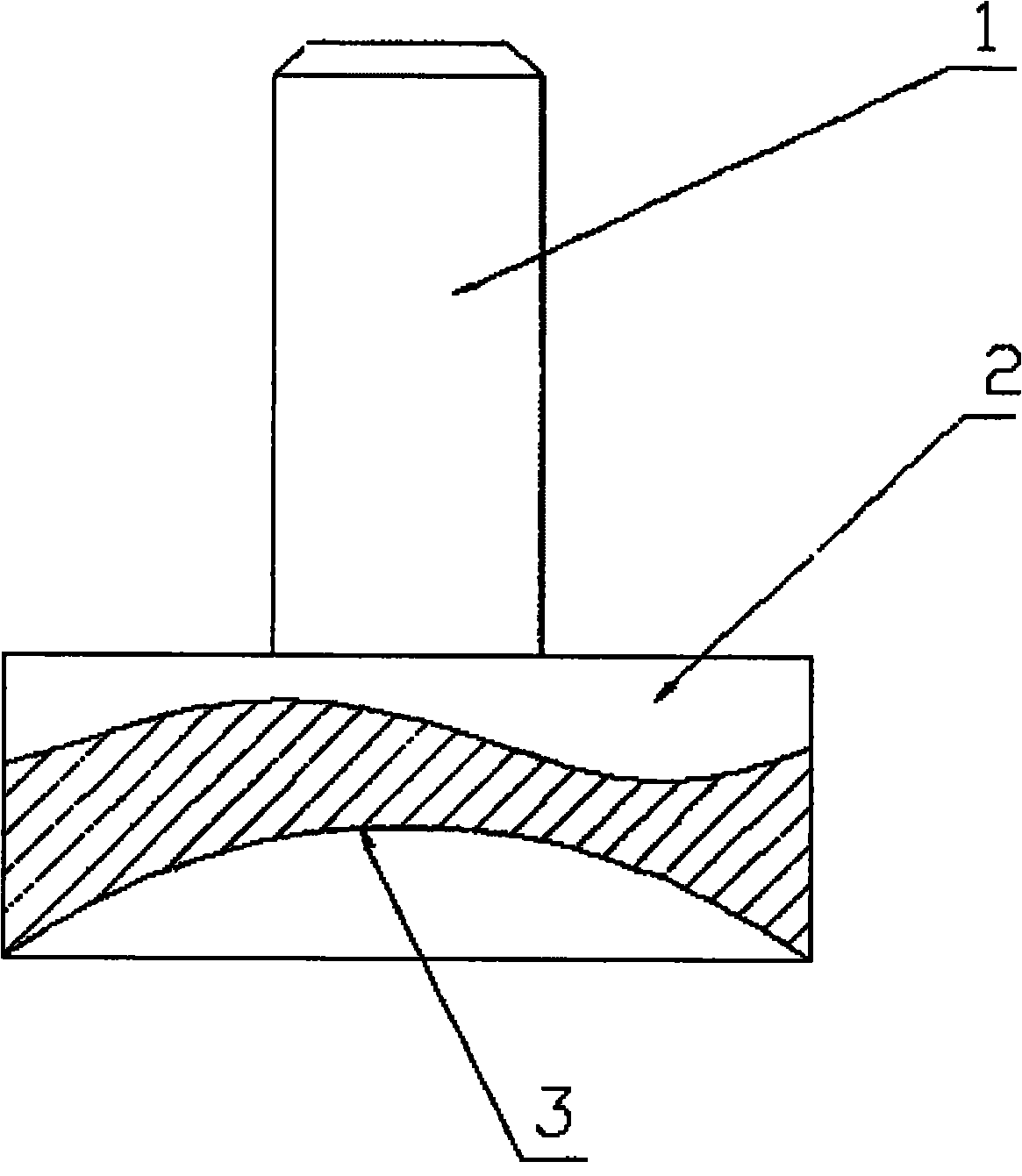

[0008] A ball socket (3) is produced on the lower plane of the punch (2), and the maximum diameter of the ball socket (3) is equal to the diameter of the outer circle of the punch (2).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A structure of a novel hole-piercing punch is characterized in that a ball socket is machined on the lower surface of the puncher pin, and the largest diameter of the ball socket is equal to the excircle diameter of the puncher pin; and in the invention, since adopting the scheme, the blade is sharper, when punching a larger hole or a thicker plate, a larger press machine is avoided to be used, and the structure has the advantages of smaller punching production and lower production cost.

Description

technical field [0001] The invention relates to a punching punch, in particular to a novel punching punch structure, which belongs to the technical field of punching dies. Background technique [0002] At present, in the structure of the punching die, the punching die is generally composed of a handle and a punch. The working surface of the punch, that is, the shearing surface, is a planar structure. Although this structure has a simple structure , has the advantages of better manufacturability and higher strength, but due to structural reasons, its blade is not sharp enough. In order to punch larger holes or thicker sheets, a larger press must be used. It requires a larger investment in stamping production, and the production cost is higher. Contents of the invention [0003] The purpose of the present invention is to provide a new structure of the punching punch, which overcomes the structural reasons of the existing punching punch. When punching larger holes or thicker...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B26F1/14B21D28/34B21D28/26

Inventor 王后平

Owner 王后平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com