Hydraulic steel pipe connector and extrusion forming method and production device thereof

A technology for steel pipe joints and extrusion molding, which is applied in the field of hydraulic steel pipe joints and their extrusion molding and production equipment, can solve the problems of unstable weld quality, organizational structure, waste of energy, labor, and wear of hydraulic components, and achieve The effect of eliminating the welding process, reducing the consumption of materials, and improving the overall hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

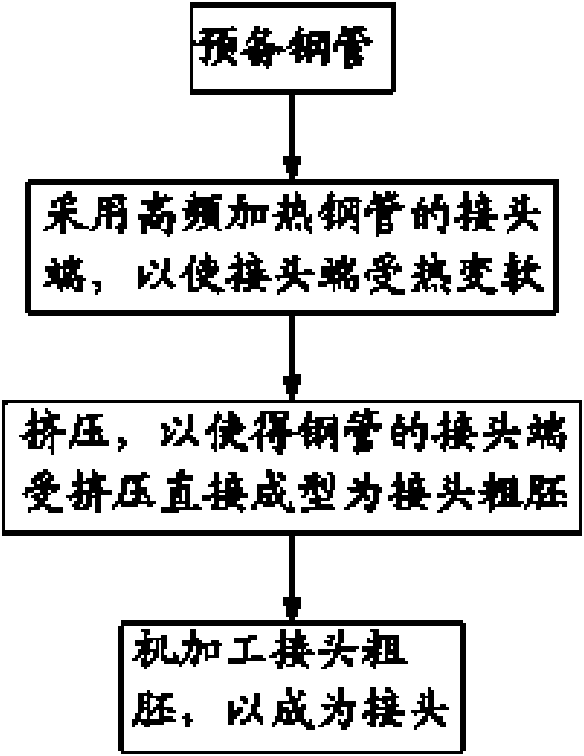

Method used

Image

Examples

Embodiment Construction

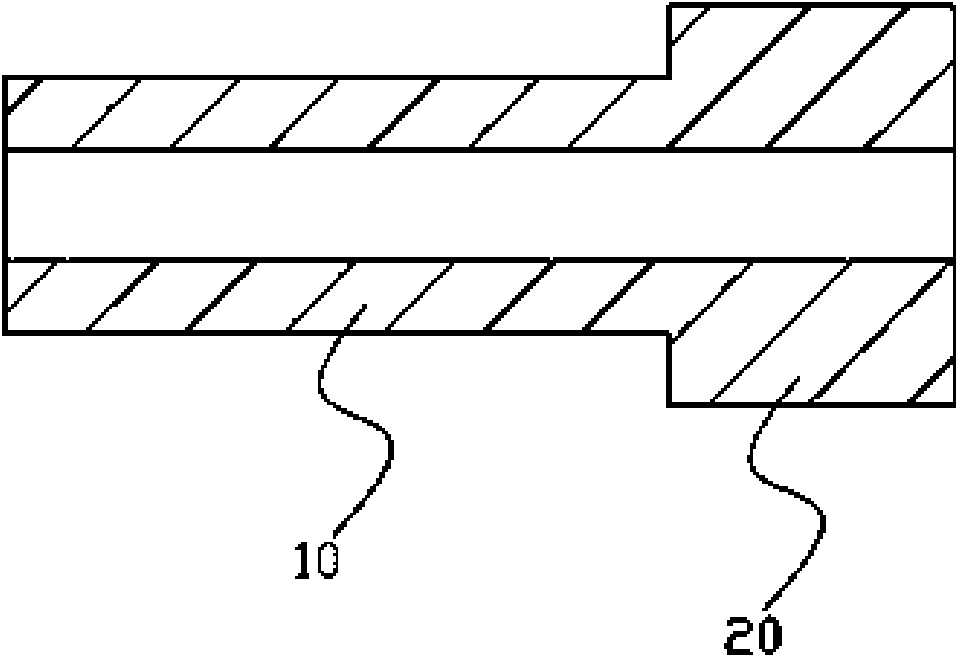

[0045] Please check figure 2 , a hydraulic steel pipe joint, which includes a steel pipe 10, the joint end of the steel pipe 10 is softened by high-frequency heating and then extruded into a joint 20.

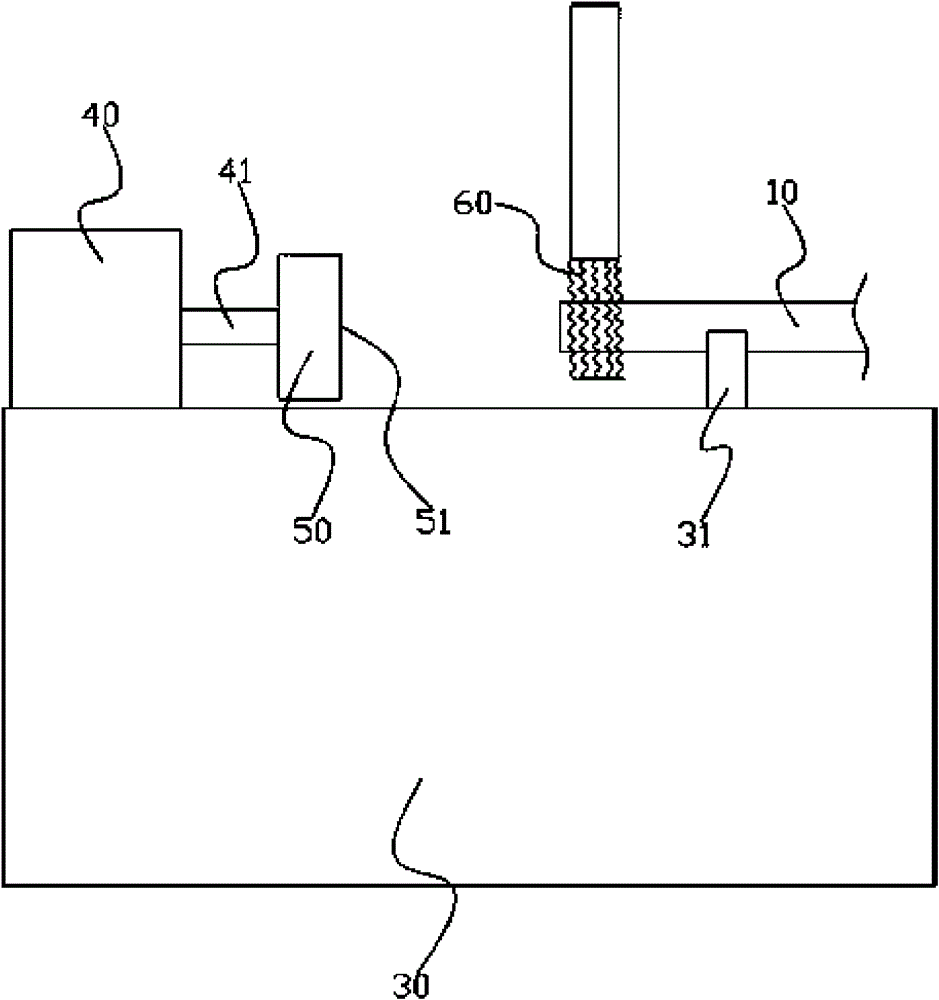

[0046] Please check image 3 , Figure 4 and Figure 5 , Hydraulic steel pipe joint production equipment, which includes a workbench 30, a hydraulic system 40, a mold 50 and a high-frequency heater 60. A tooling 31 is arranged on the workbench 30 , and the tooling 31 is used as a fixture for positioning the steel pipe 10 , and the joint end of the steel tube is located outside the tooling 31 after positioning. The hydraulic system 40 is fixed on the workbench 30, and the hydraulic system 40 has a slidable hydraulic rod 41, and the hydraulic rod 41 slides between the original position and the working position. The mold 50 has a mold surface 51 and a molding cavity 52 , the opening of the molding cavity 52 is located on the mold surface 51 , and the mold surface 51 faces the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com