Cluster controlled heat pump hot water system

A heat pump hot water, cluster control technology, applied to fluid heaters, lighting and heating equipment, etc., can solve the problems of the failure of the module machine cannot be effectively fed back to the control cabinet, the effective water supply cannot be guaranteed, and the equipment operation reliability is poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

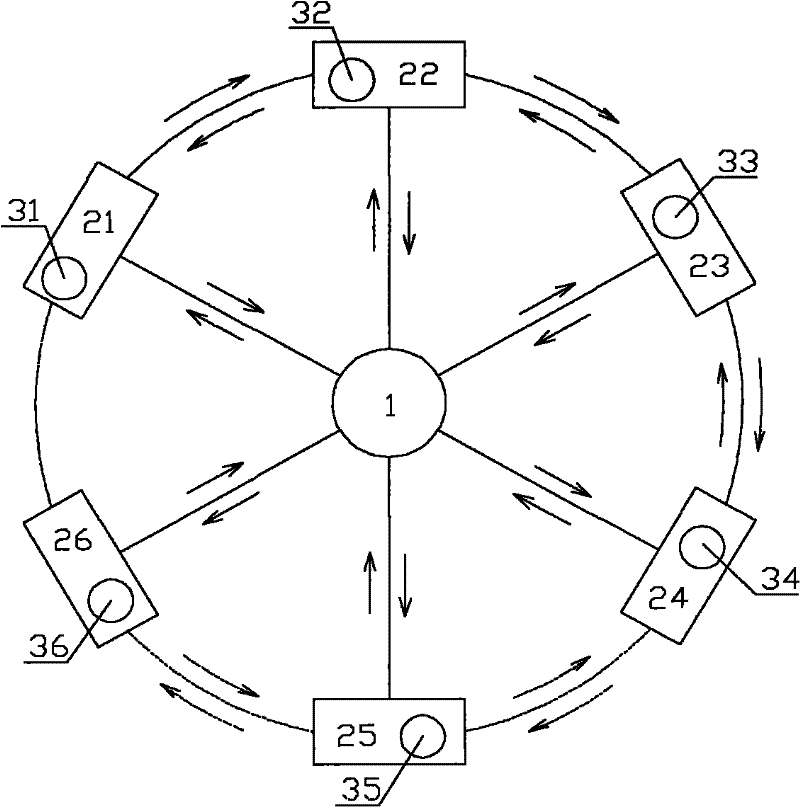

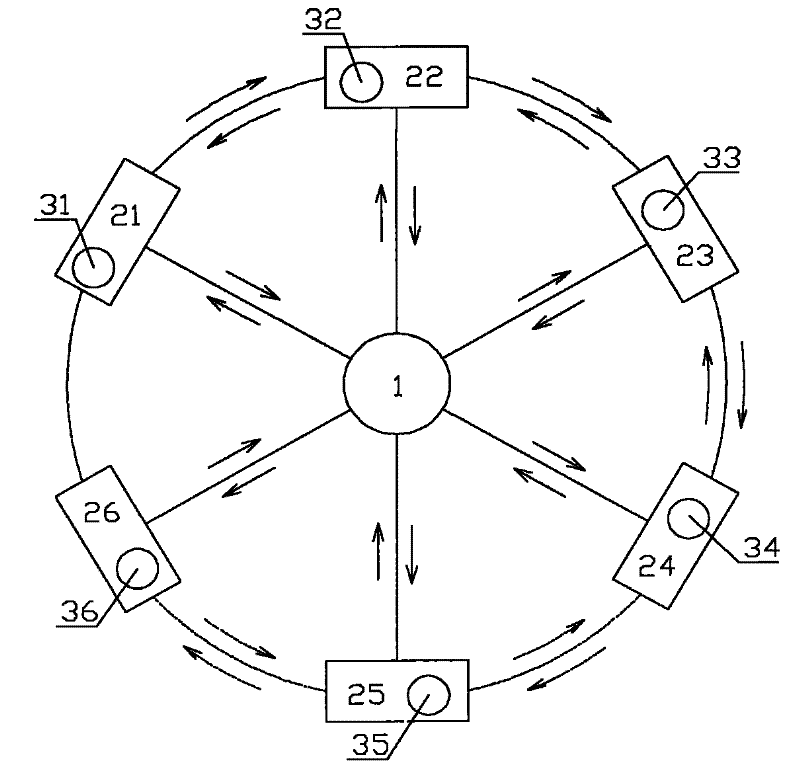

[0007] The working conditions of this system are described below with the situation of 6 module machines. figure 1 Among them, the main control cabinet (1) and module machine A (21), module machine B (22), module machine C (23), module machine D (24), module machine E (25), and module machine F (26) A star topology structure for two-way communication, module machine A (21), module machine B (22), module machine C (23), module machine D (24), module machine E (25), module machine F (26) Form a ring topology in turn.

[0008] When working, the main control cabinet (1) sends a start signal to the module machine A (21) with the shortest running time. After the module machine A (21) starts, it sends its own running status to the main control cabinet ( 1) and other modular machines, when the modular machine A (21) breaks down and cannot operate normally, the main control cabinet (1) will search and start the modular machine B (22) with the shortest total running time among the rema...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com