Concentrated, creamy to solid and dry compositions of oil-in-water emulsion, method for production thereof and use thereof for producing improved foods in terms of sensory aspects and nutrition physiology

A technology of oil-in-water, composition, applied in the field of composition based on biopolymers, which can solve the problem of not describing water-in-oil emulsion, etc., and achieve the effect of simple and continuous production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

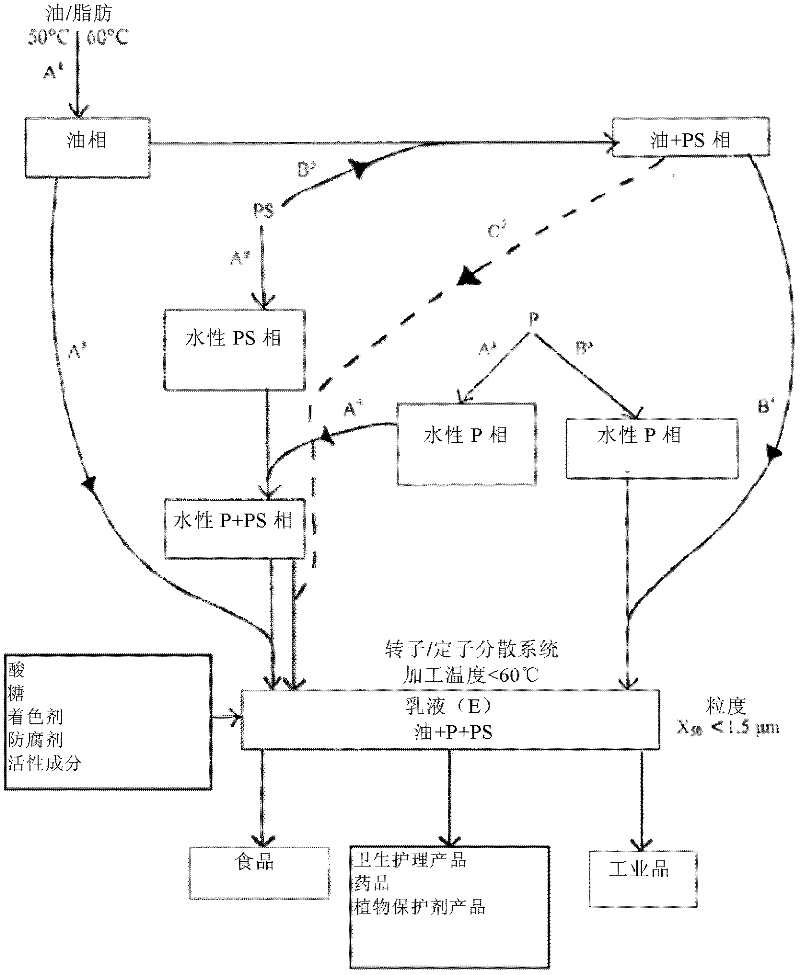

Method used

Image

Examples

preparation example Construction

[0069] Preparation of Dosage Forms

[0070] In one embodiment, an emulsion having a liquid and viscous consistency is used in slow mixing with a flowable to liquid base material preferably having an acidic pH, such as a sauce or a buffered solution for, for example, a biologically active protein, or it can be Use or dispose immediately to get desired product. Although most applications advantageously involve mixing the PPS into the corresponding base stock, it has proven advantageous to slowly mix highly acidic solutions into the PPS so that the pH does not drop too rapidly.

[0071] In another embodiment, an emulsion having a creamy to pasty consistency is mixed into a viscous, pasty, spreadable or doughy base material, preferably having a neutral pH, to obtain the corresponding product. If desired, the pH of the basic food raw material can be lowered, for example, by acidification with acids which are also customary in the respective products, such as lactic acid or citri...

Embodiment 1

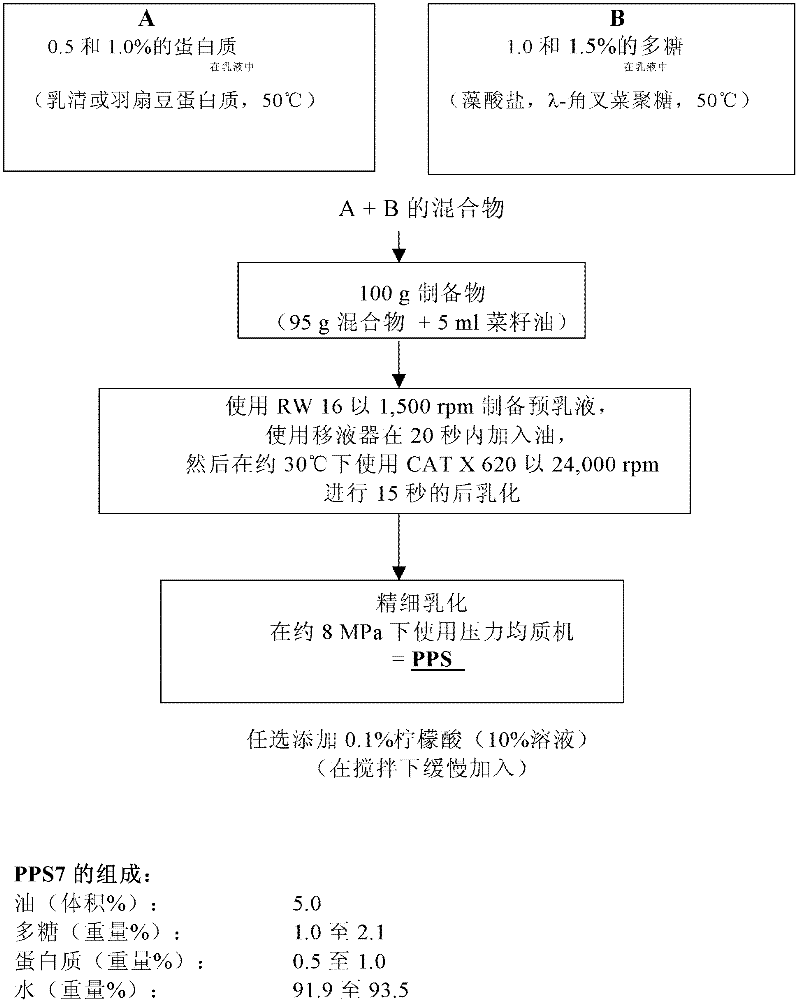

[0238] Example 1: Example of providing a PPS emulsion according to variant A

[0239] Preparation of emulsion

[0240] Whey and lupine proteins and polysaccharides were dissolved separately using a stirring unit RW 16 equipped with a star stirrer, and then the individual protein and polysaccharide solutions were mixed in different ratios (by variation of the protein and polysaccharide concentrations used and by the protein / polysaccharide changes in polysaccharide ratio). Whey and lupine protein as well as alginate and carrageenan were dissolved at 50°C with stirring and the dispersed pullulan was heated to 90°C until a light colored and highly viscous solution was obtained. In the solubility experiments it was determined at what polysaccharide content the aqueous phase would still maintain suitable flow properties, ie still be flowable.

[0241] like Figure 2A As shown in , rapeseed oil was dispersed in 95 ml protein / polysaccharide solution using a star mixer (stirrer un...

Embodiment 2

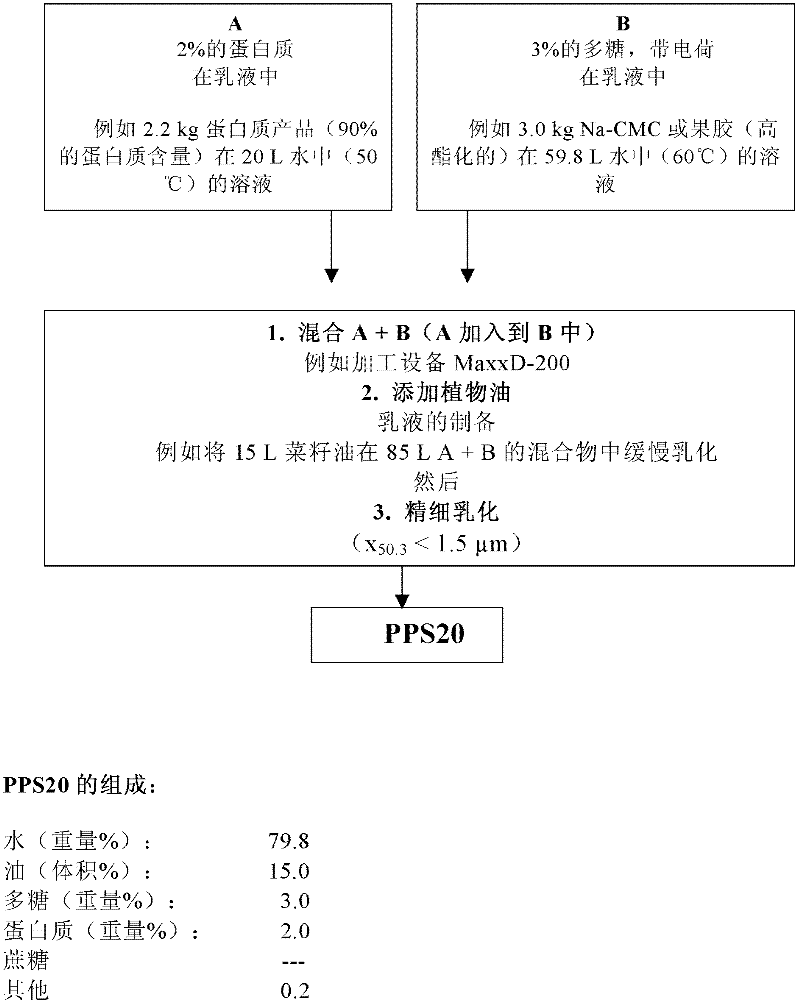

[0257] Example 2: Preparation of PPS emulsion according to variant B of the process of the invention and its use in the production of organic beverages

[0258] For the production of beverages, especially organic beverages, preferably according to figure 1 and 3 Variant B shown in the schematic diagram of , the emulsion is prepared by mixing the oil phase with the polysaccharide under stirring and then dispersing the resulting mixture in the protein-containing aqueous phase using a high-pressure emulsifier, e.g. according to November 2007 German patent application DE 102007057258.3 filed on 27th " -in-Wasser-Emulsion für Bio-Lebensmittel sowie deren Herstellung und Verwendung", the disclosure content of this patent application, especially the examples, is incorporated by reference in the description of the present application.

[0259] For the purpose of illustration, here is essentially described Example 2 of document DE 102007057258.3 for the production of emulsions of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com