Belt wrapper

A technology of a winder and a belt, applied in the field of auxiliary winding of thin strips, can solve the problems of poor guiding function and lack of guiding devices, and achieve the effects of reducing wear, saving space, and small turning radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

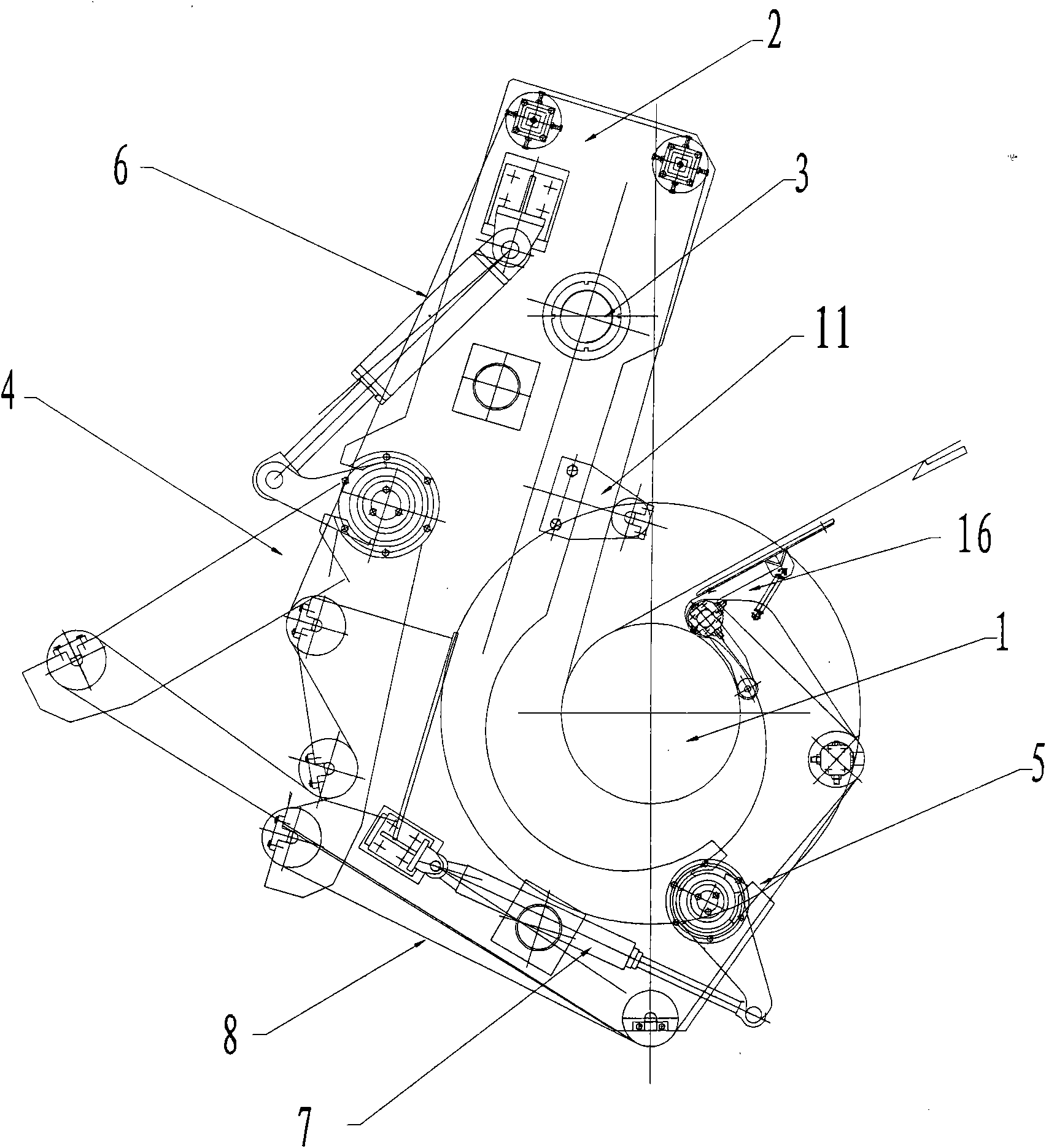

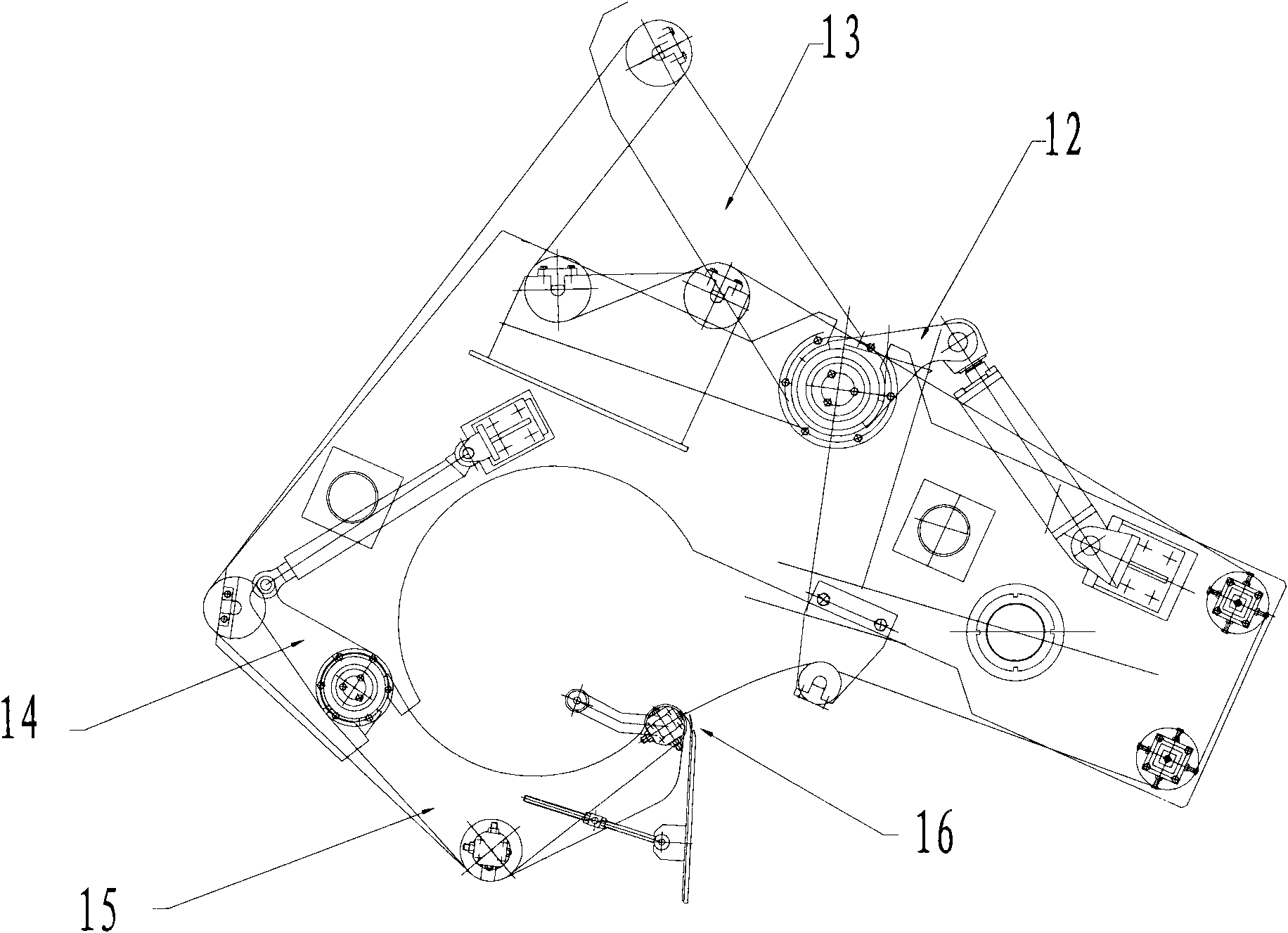

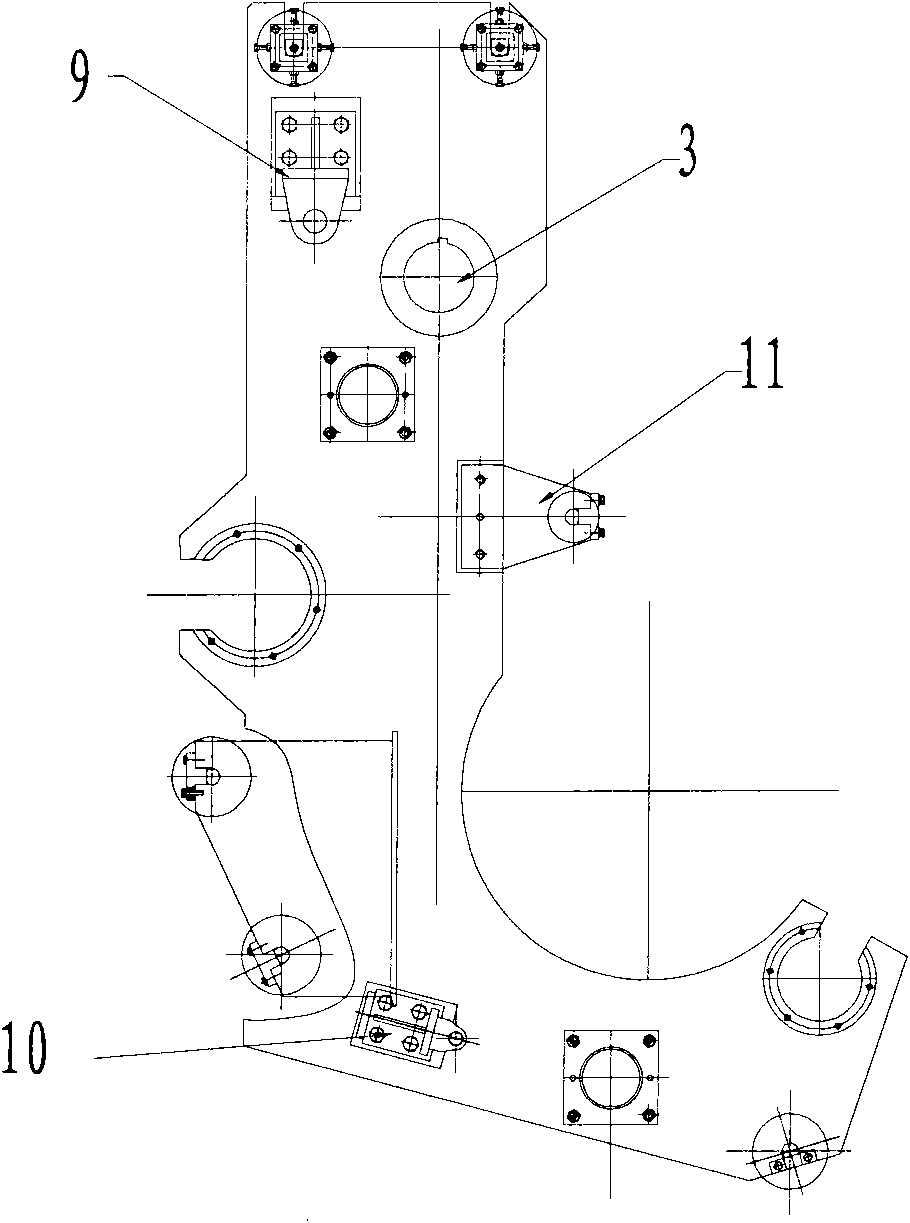

[0014] Attached below figure 1 , figure 2 , image 3 , Figure 4 The specific embodiment of the invention will be described in detail.

[0015] Such as figure 1 , 2 , 3 and 4, the guided belt roll aid includes a roll aid main body 2, a retractable device 4, a swing guide 5, a retractable device cylinder 6, a swing guide cylinder 7, and a belt 8. The main body 2 of the roll aid, the retracting device 4, the swing guiding device 5 and the pressure roller device 11 are all provided with support rollers, and the belt 8 is wound around the support rollers. The function of the pressure roller device in this embodiment is to block the belt 8 to prevent the belt 8 from being vertical to the reel in a non-working state, which hinders the normal operation of the reel 1 .

[0016] The main body 2 of the winding aid is mainly composed of the main shaft seat 3, the first support 9, the second support 10 and the pressure roller device 11, the retracting device 4 is composed of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com