Fireproof door frame

A technology for door frames and wooden boards, which is applied in the direction of fire doors, window/door frames, etc., can solve the problems of decoration effect discount, door panel scrapping, etc., and achieve the effects of simple structure, liberation and promotion of productivity, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

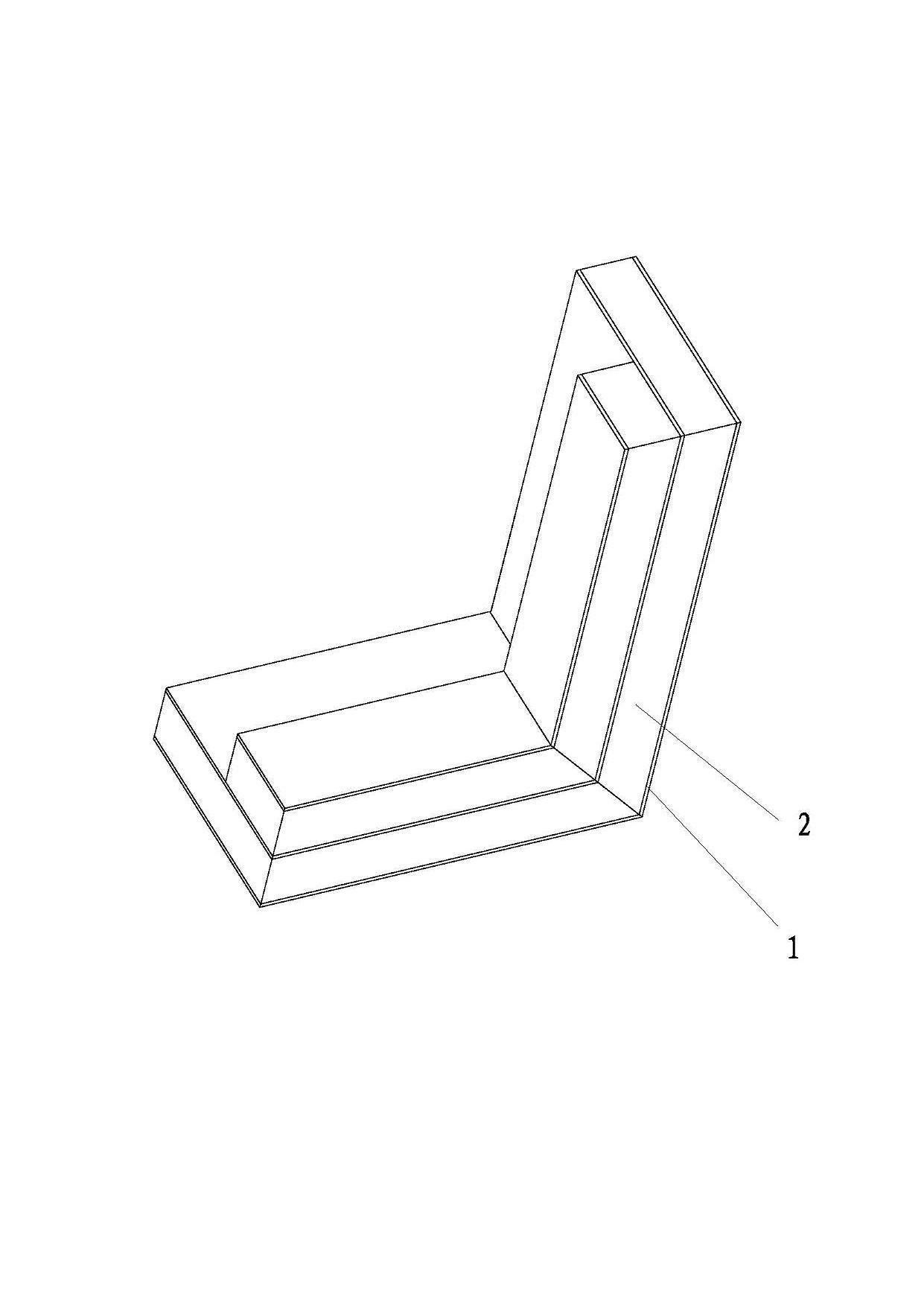

[0018] Such as figure 1 As shown, a fireproof door frame consists of three layers of magnesium material (1) and a wooden board layer (2) sandwiched therein, and the gap between the magnesium material layer (1) and the wooden board layer (2) Bonded by glue. The wooden boards of the wooden board layer (2) are waste wood boards, and the waste wood boards are formed by bonding small pieces of wood. Magnesium material layer (1) is obtained by dispersing magnesium oxide powder with a purity of 80% in a magnesium chloride solution with a Baume degree of 23 degrees, then stirring to prepare a paste, and finally hardening the paste. The thickness of the magnesium material layer is 0.3cm, and the thickness of the wooden board layer (2) is 2cm.

Embodiment 2

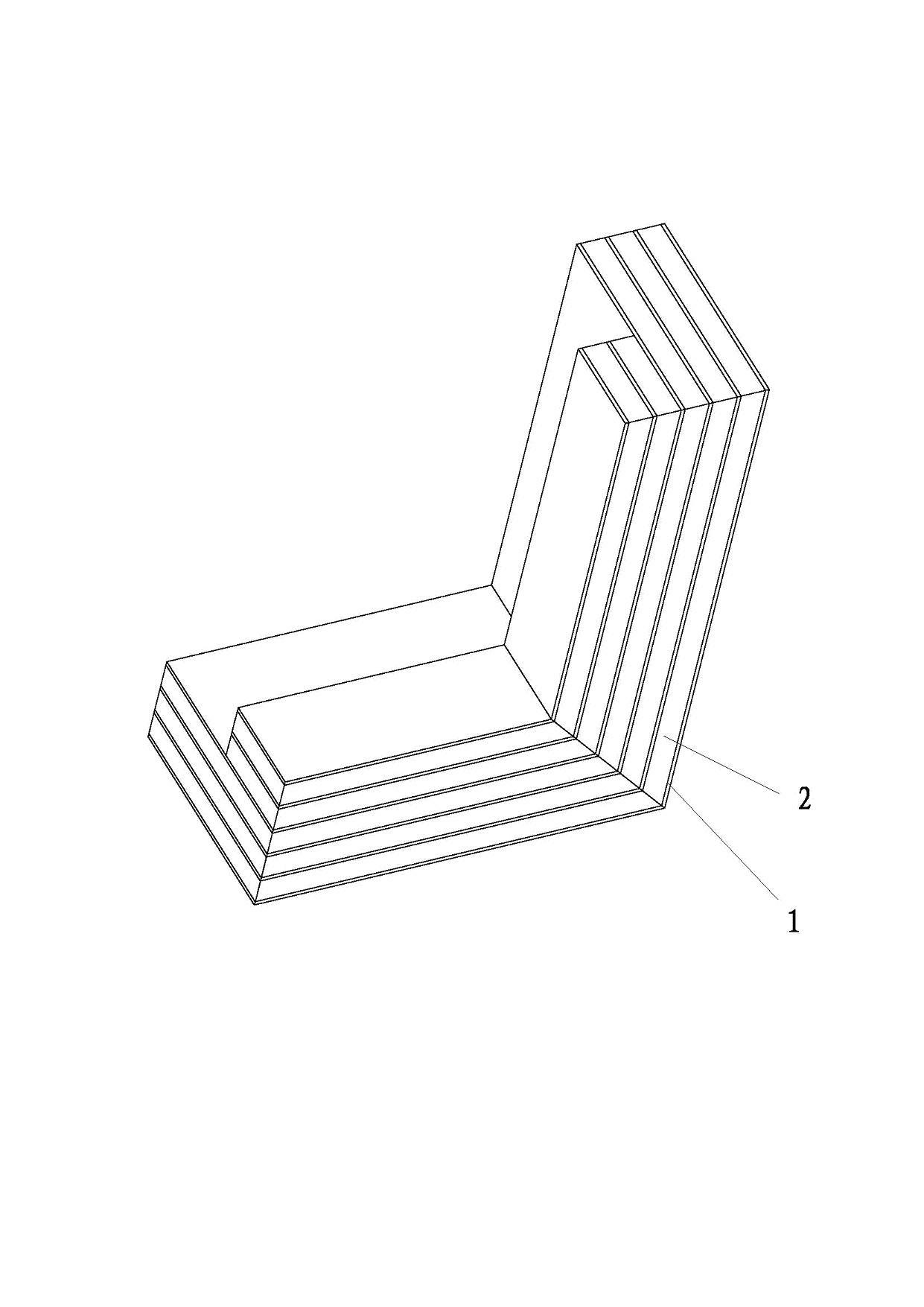

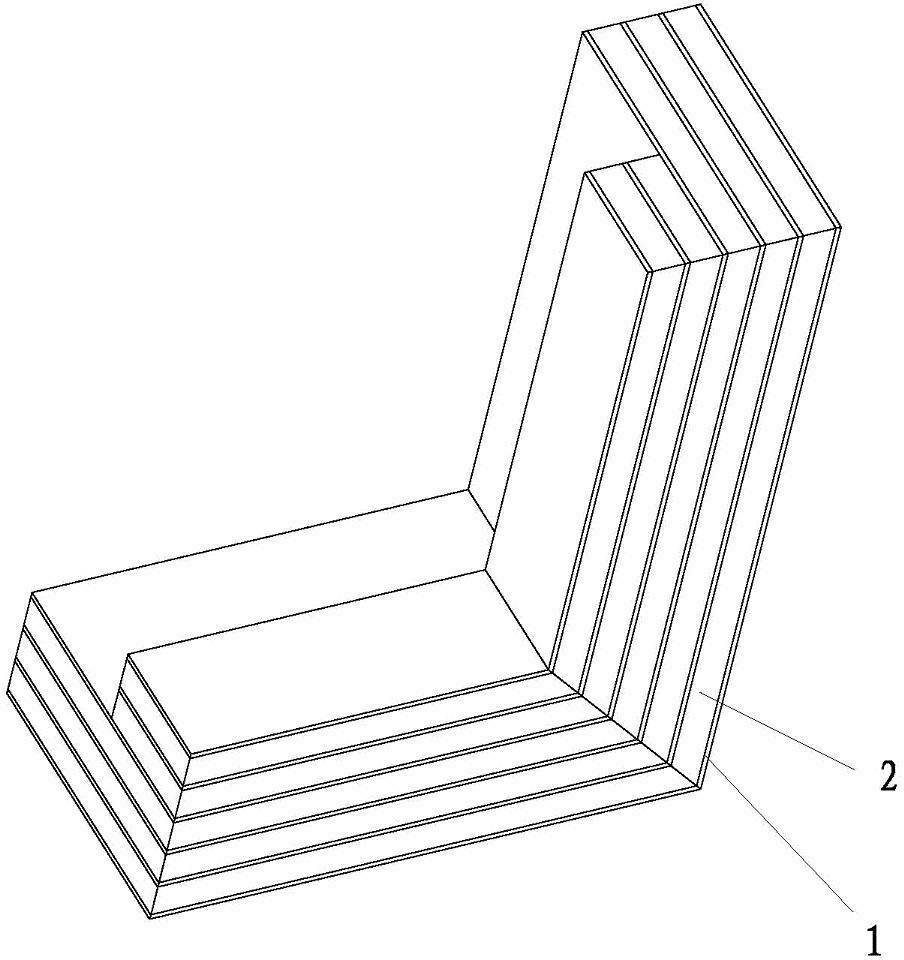

[0020] Such as figure 2 As shown, a fireproof door frame is composed of six layers of magnesia material layers (1) and a wooden board layer (2) interposed therein, between the magnesium material layer (1) and the wood board layer (2) Bonded by glue. The wooden boards of the wooden board layer (2) are waste wood boards, which are formed by adding an adhesive to wood chips and then through a hot pressing process. Magnesium material layer (1) is obtained by dispersing magnesium oxide powder with a purity of 80% in a magnesium chloride solution with a Baume degree of 23 degrees, then stirring to prepare a paste, and finally hardening the paste. The thickness of the magnesium material layer is 0.2cm, and the thickness of the wooden board layer (2) is 1.5cm.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap