Side-light back light module

A backlight module and edge-lit technology, which is applied in the field of edge-lit backlight modules, can solve the problems of complicated and difficult optical design of light guide plates, and achieve the best light enhancement effect and the effect of improving the positive brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0024] The foregoing and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of three preferred embodiments with reference to the drawings.

[0025] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same numerals.

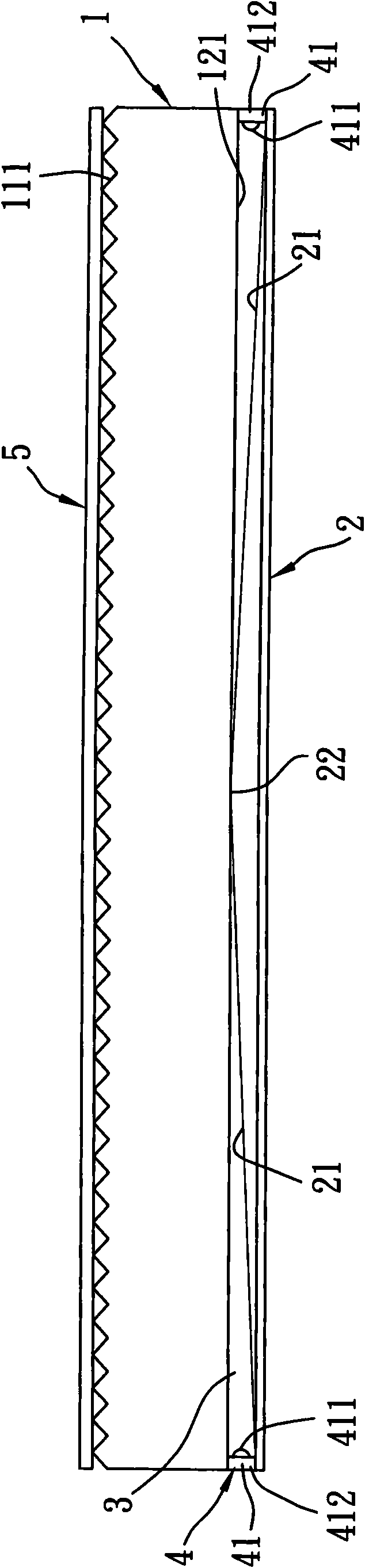

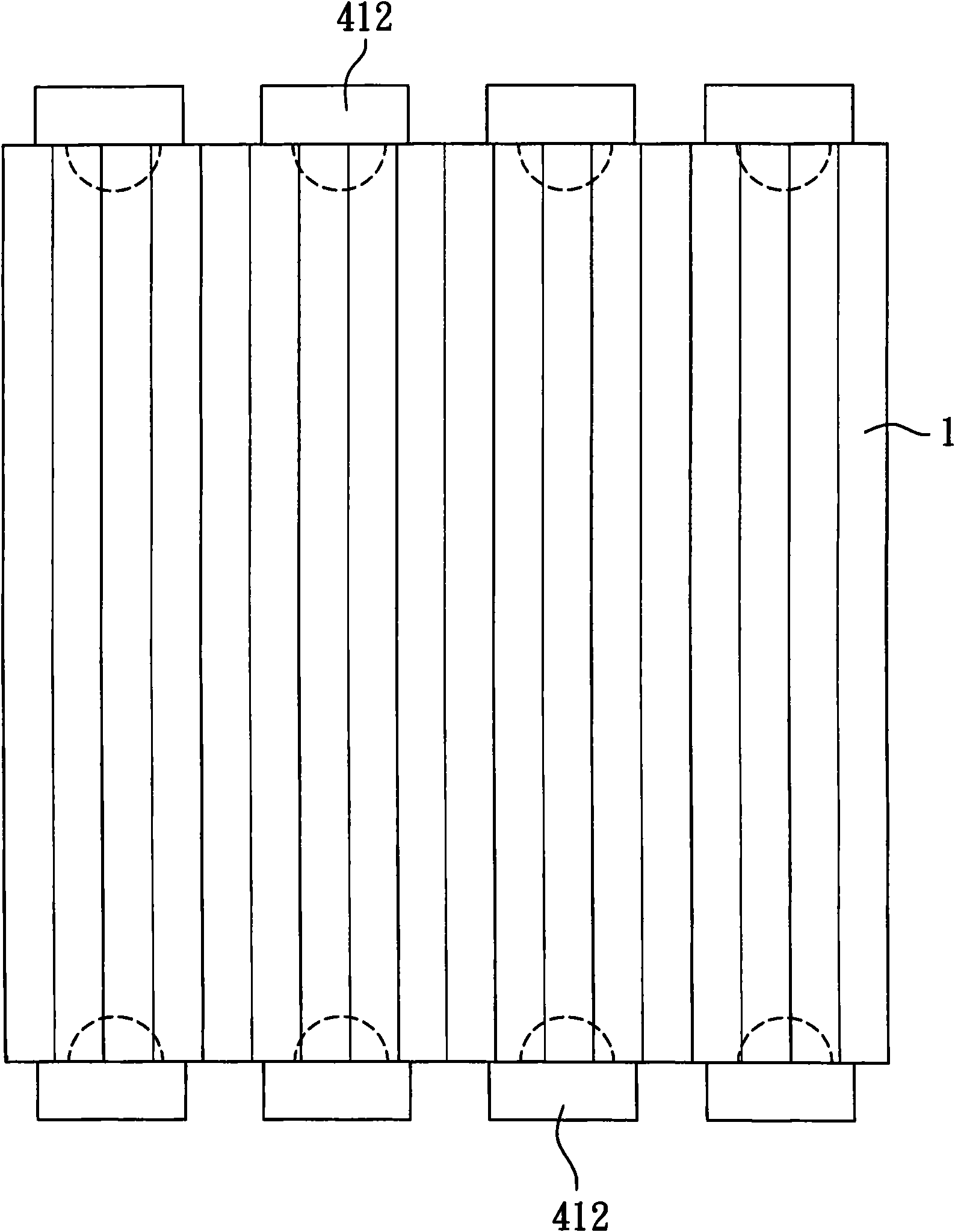

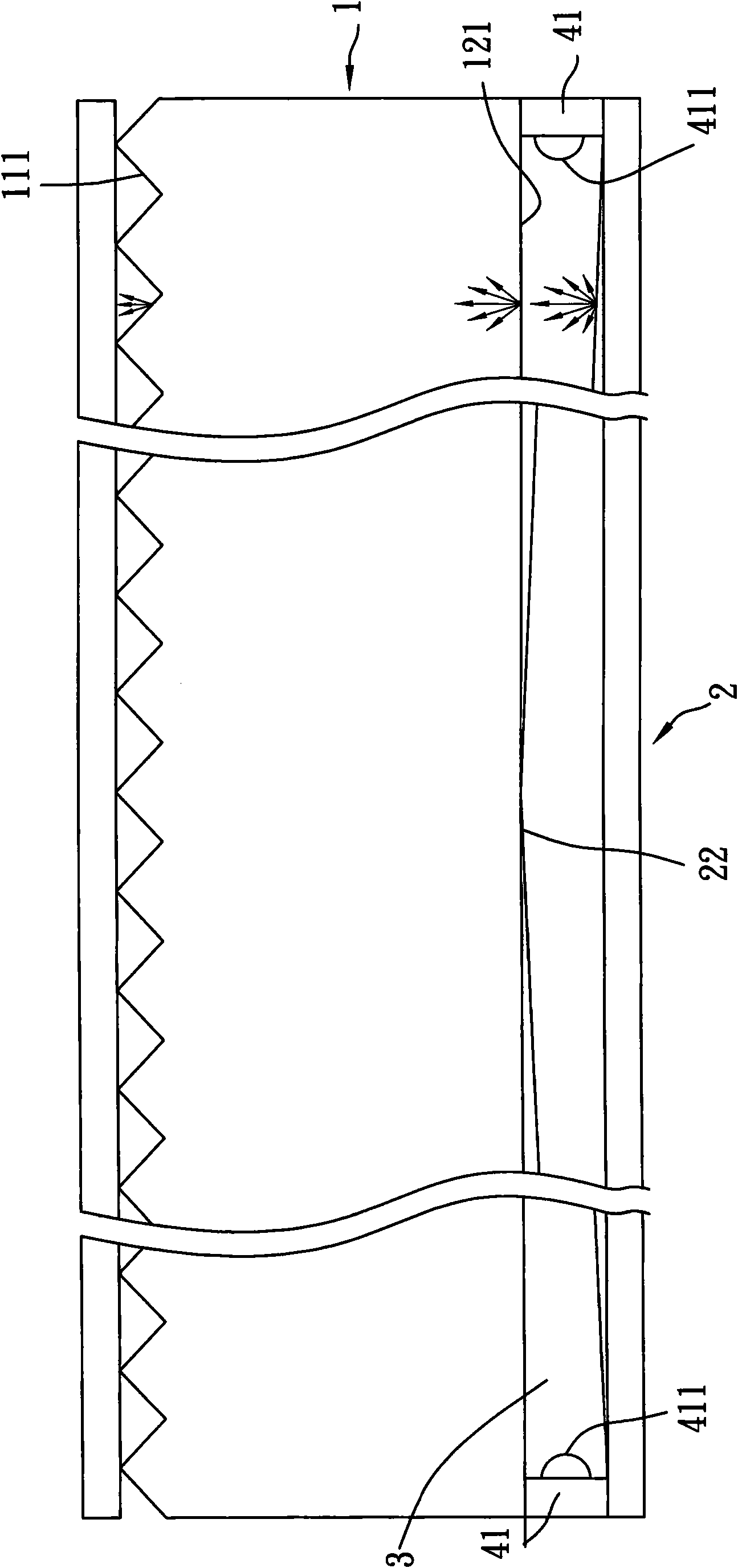

[0026] refer to figure 1 , figure 2 , image 3 , The first preferred embodiment of the edge-lit backlight module of the present invention includes a microstructured optical plate 1 , a reflective plate 2 , a light emitting device 4 and a diffusion film 5 . The microstructured optical plate 1 is composed of transparent methyl methacrylate resin (PMMA resin), and includes a light-emitting surface 111 and a light-incident surface 121 located on the opposite side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com