Driver for cooperating with a wall dimmer

一种驱动器、调光的技术,应用在驱动器领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

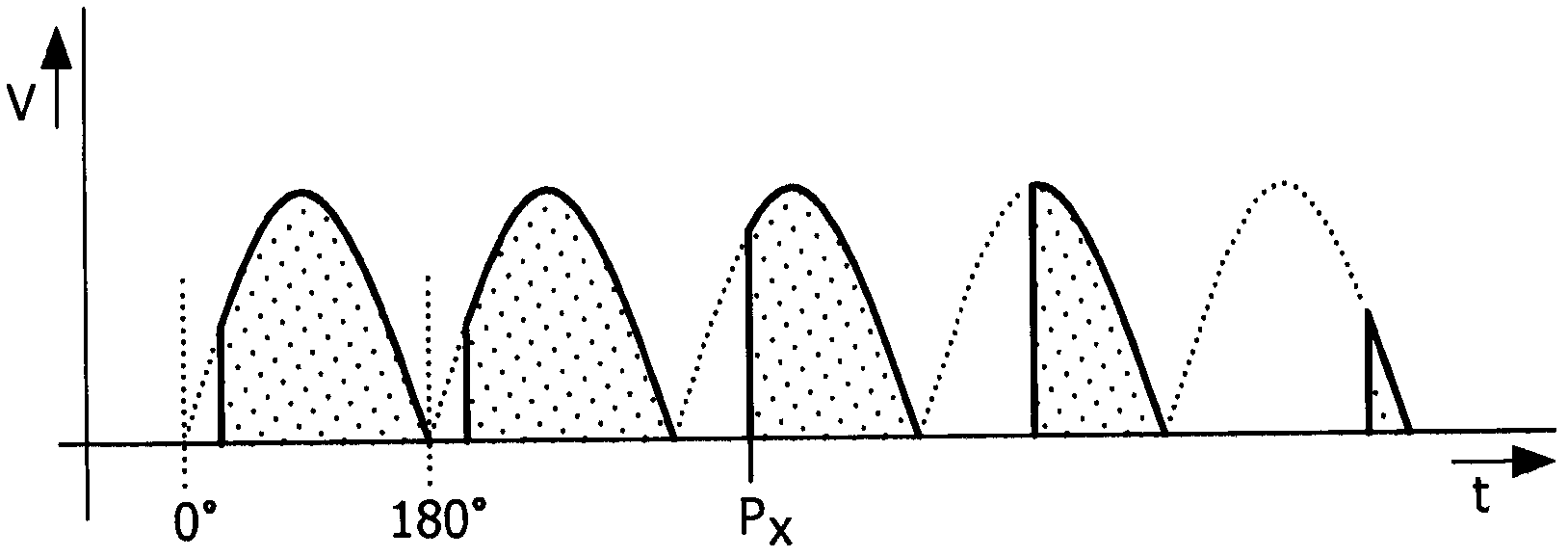

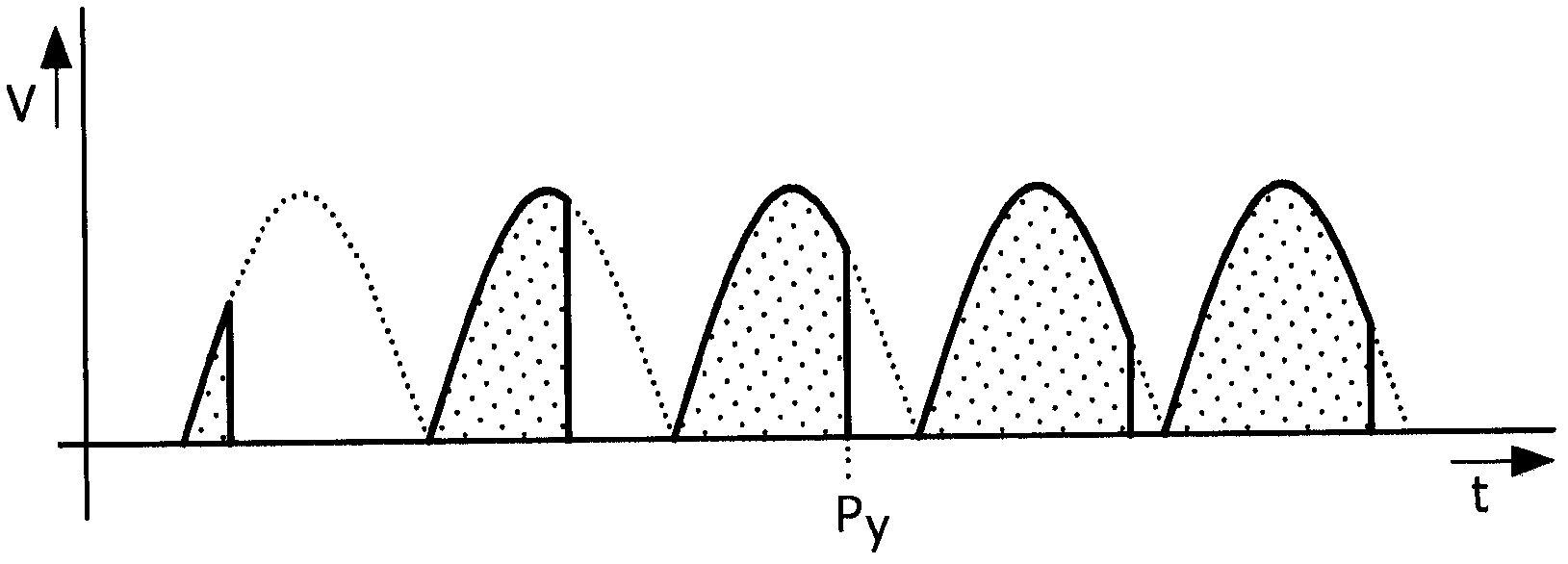

[0018] image 3 is a block diagram schematically illustrating one embodiment of an electronic driver 100 according to the present invention. The driver 100 has an input 101 for receiving phase cut mains U1 from a mains dimmer (not shown) and an output 109 for connection to a lamp L. FIG.

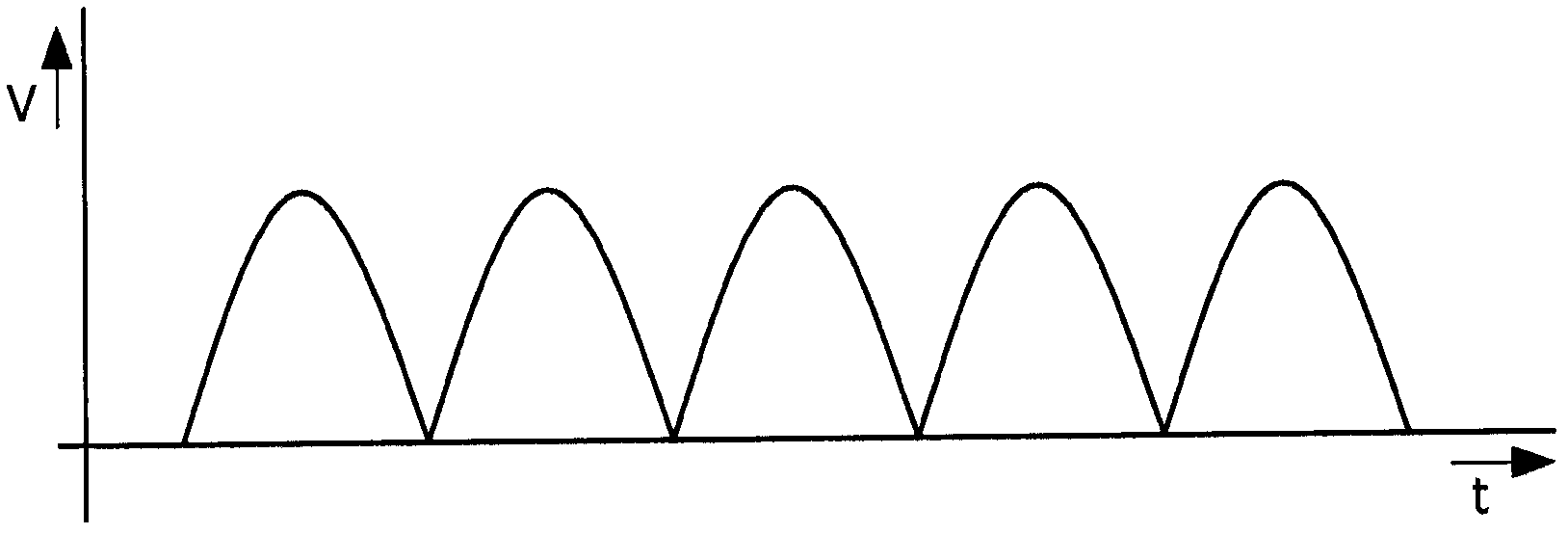

[0019] The rectifier 110 has an input 111 connected to the driver input 101 and has an output 119 for providing rectified mains U2. The rectifier 110 can be implemented, for example, as a diode bridge. It should be noted that rectified mains U2 has essentially the same waveform as mains U1, with the difference that the polarity of all current half-cycles is now the same. Since rectifiers are well known to those skilled in the art, a more detailed discussion of the design or operation of rectifier 110 need not be discussed here.

[0020] The DC / DC converter 120 has an input 121 connected to the rectifier output 119 and has an output 129 for providing a substantially constant output voltage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com