Double-array movable bobbin creel

A creel and sprocket technology, applied in creel, textile and papermaking, manufacturing tools, etc., can solve the problem of inconvenience for operators to put on the bobbin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

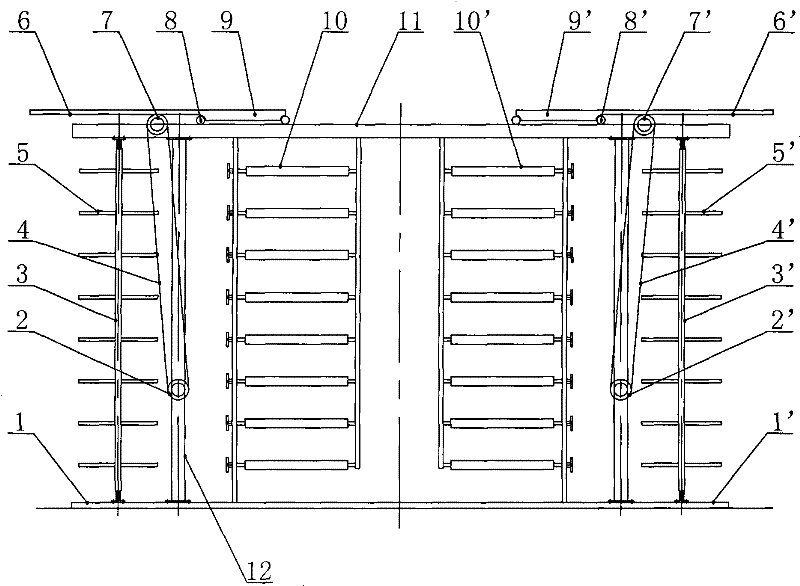

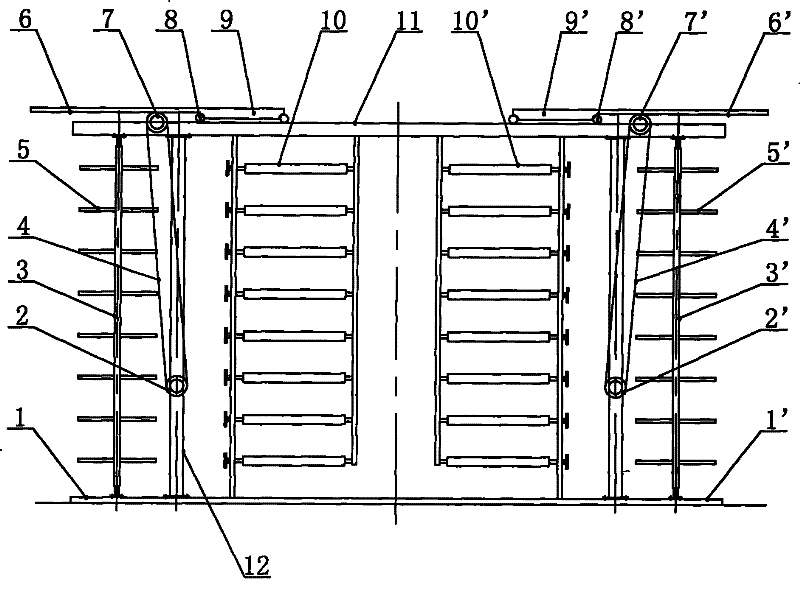

[0008] Such as figure 1 As shown, the double-row movable creel of the present invention includes a base 1, a column 12 connected to the base and a beam 11 connected to the top of the column. The creels are symmetrically arranged on the left and right sides, and there are multiple rows from front to back , the middle part of the first row of the creel is provided with a plurality of static elimination rods 10, and the creel is provided with a moving device 9, which includes a rack 6, a roller 8, an upper sprocket 7 and a lower sprocket 2, and is responsible for the overall movement of the creel. Moving to both sides or in the middle, the lower sprocket 2 is provided with a coaxial rocker, the lower sprocket 2 and the upper sprocket 7 are connected through the transmission of the chain 4, and the upper sprocket 7 is provided with coaxial gears, the gear and the rack 6 meshes, and roller 8 is positioned on the track on crossbeam 11 upper surface; Upper sprocket shaft is driven fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com