Filtering equipment used for solid-liquid separation

A filtration equipment and solid-liquid separation technology, which is applied in the direction of fixed filter element filter, filtration separation, separation method, etc., can solve the problems of large size and complex structure, and achieve the effect of reducing consumption expenditure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

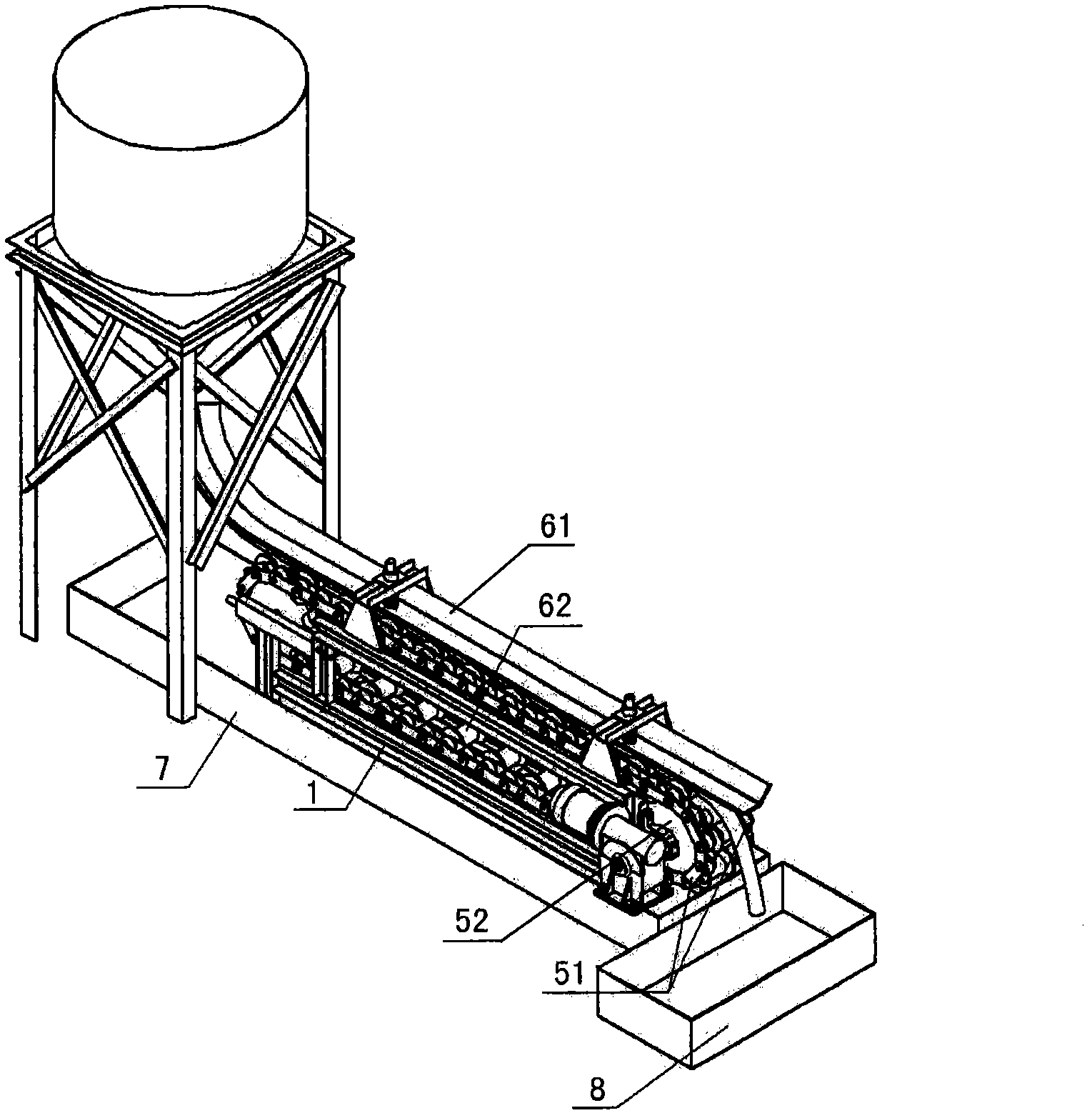

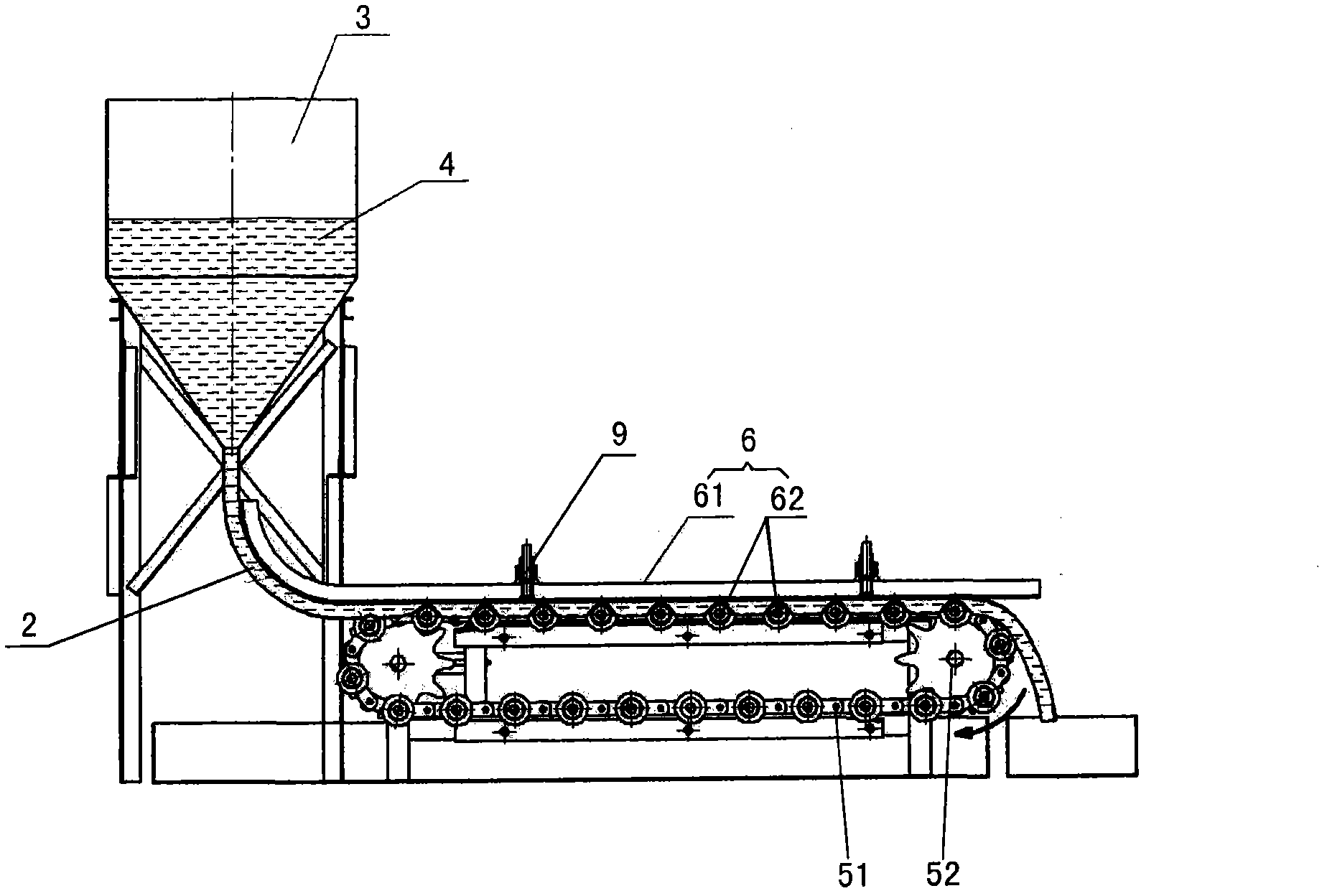

[0018] The filtering device for solid-liquid separation according to the first embodiment of the present invention is shown in the appended Figure 1-2 middle. The filter equipment includes: a support frame 1; a filter cloth hose 2, which can allow liquid to permeate, and one end of which is connected to a solid-liquid mixture supply device 3, so that the solid-liquid mixture 4 is supplied to the filter. Cloth hose 2; and a squeeze device 6 supported on the support frame 1, used to squeeze the filter cloth hose 2 for solid-liquid separation, and push the separated solids from the filter cloth The other end (free end) of hose 2 is discharged.

[0019] In one embodiment, one end of the filter cloth hose 2 connected to the solid-liquid mixture supply device 3 is set higher than other parts of the filter cloth hose 2, and the separated solids of the filter cloth hose 2 are discharged The other end (free end) of the filter cloth hose is set lower than other parts of the filter cl...

no. 2 example

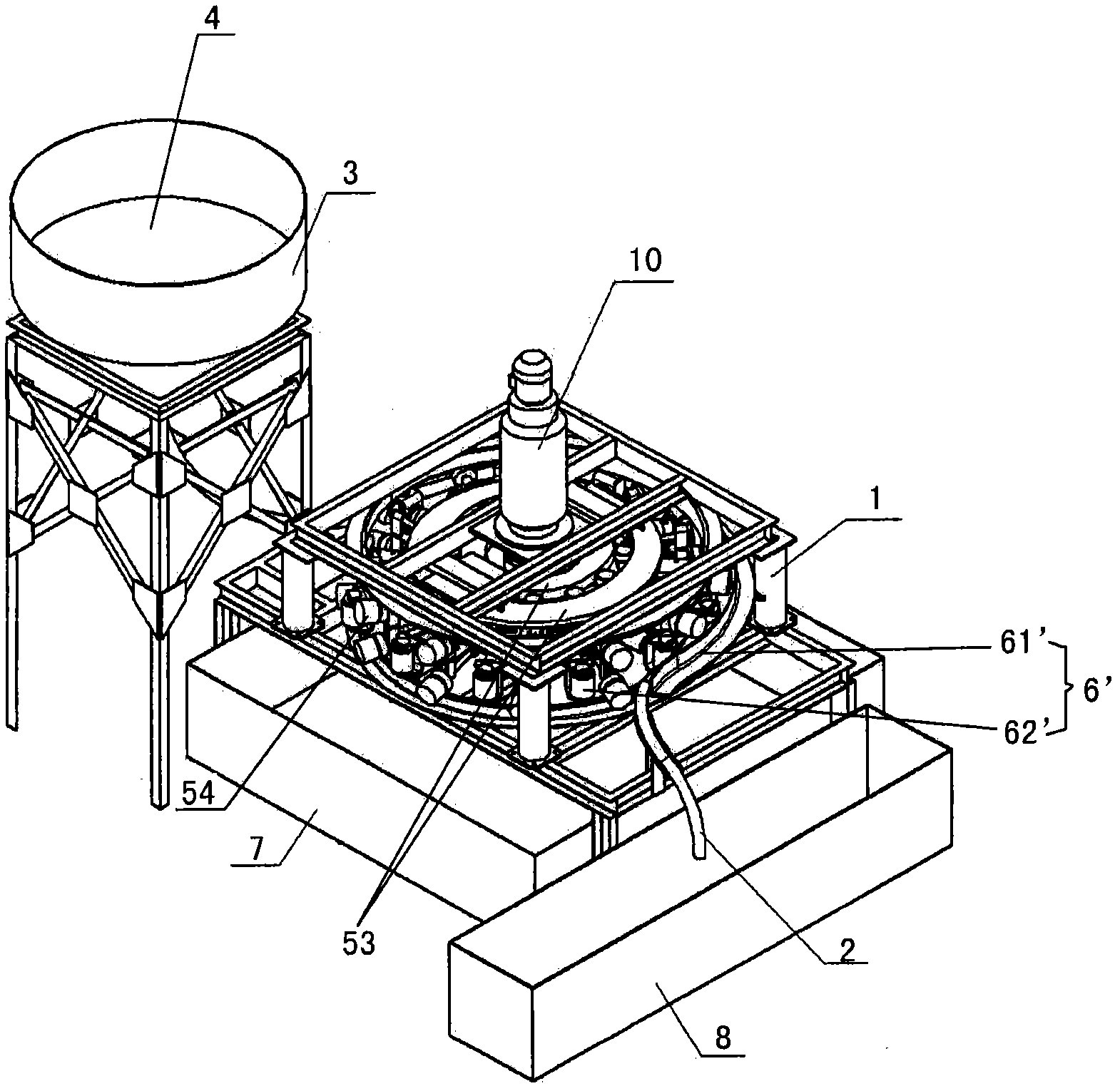

[0026] A filtration device for solid-liquid separation according to a second embodiment of the present invention is shown in the appended image 3 , where the same components are denoted by the same reference numerals. In this embodiment, the filter equipment includes: a support frame 1; a filter cloth hose 2, which can allow liquid to pass through, and one end of which is connected to a solid-liquid mixture supply device 3, so that the solid-liquid mixture 4 is supplied to the filter cloth hose 2; and the extrusion device 6' supported on the support frame 1 is used to squeeze the filter cloth hose 2 for solid-liquid separation, and pushes the separated The solids are discharged from the other end (free end) of the filter cloth hose 2.

[0027] In one embodiment, one end of the filter cloth hose 2 connected to the solid-liquid mixture supply device 3 is set higher than other parts of the filter cloth hose 2, and the separated solids of the filter cloth hose 2 are discharged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap