Bearing platform cable-stayed precast assembled column bearing platform structure and assembling and positioning process thereof

A prefabricated assembly and inclined-tensioning technology, which is applied in the erection/assembly of bridges, bridge parts, bridges, etc., can solve the problems that the assembly construction positioning technology is not introduced in detail, and the positioning of bridge piers is difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

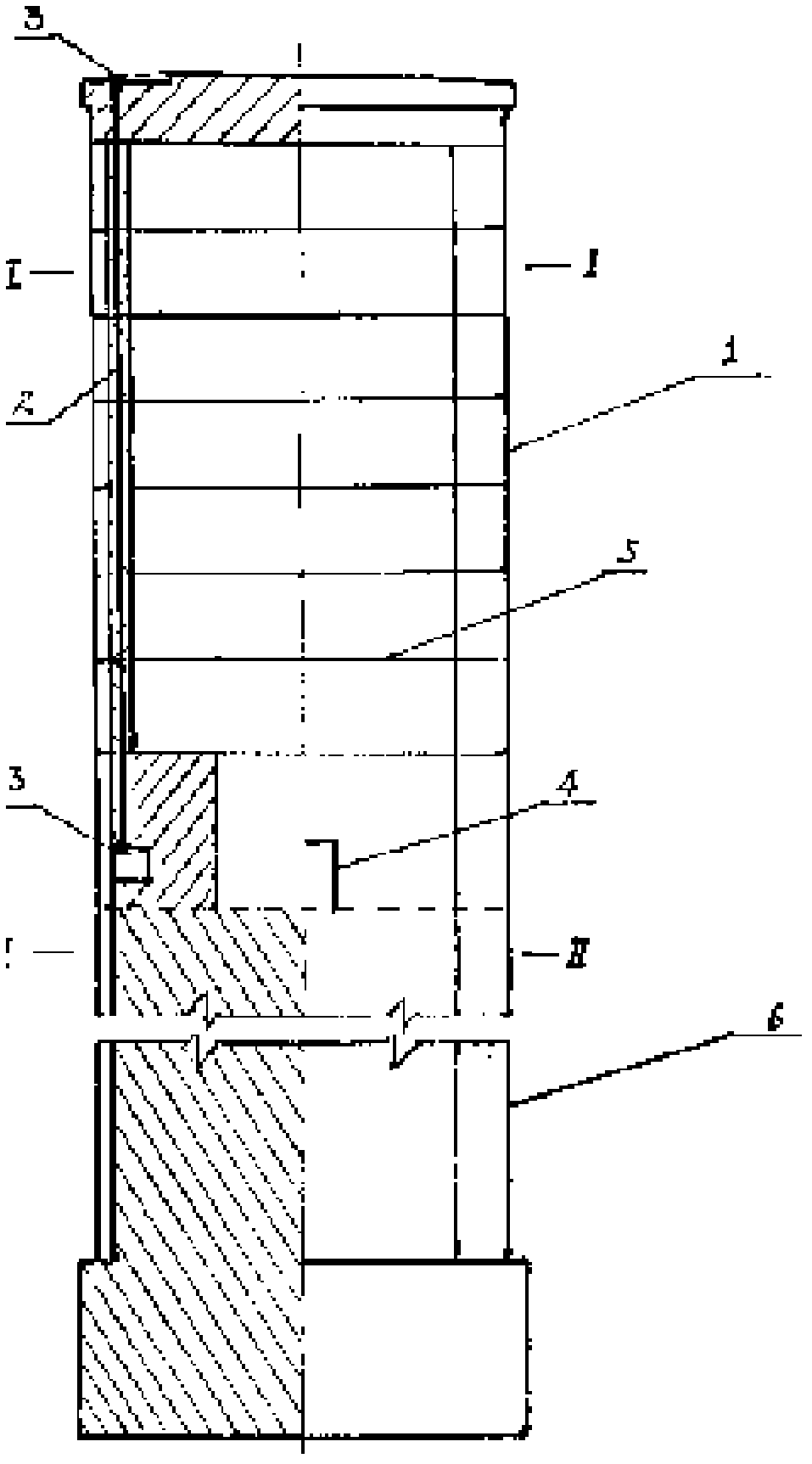

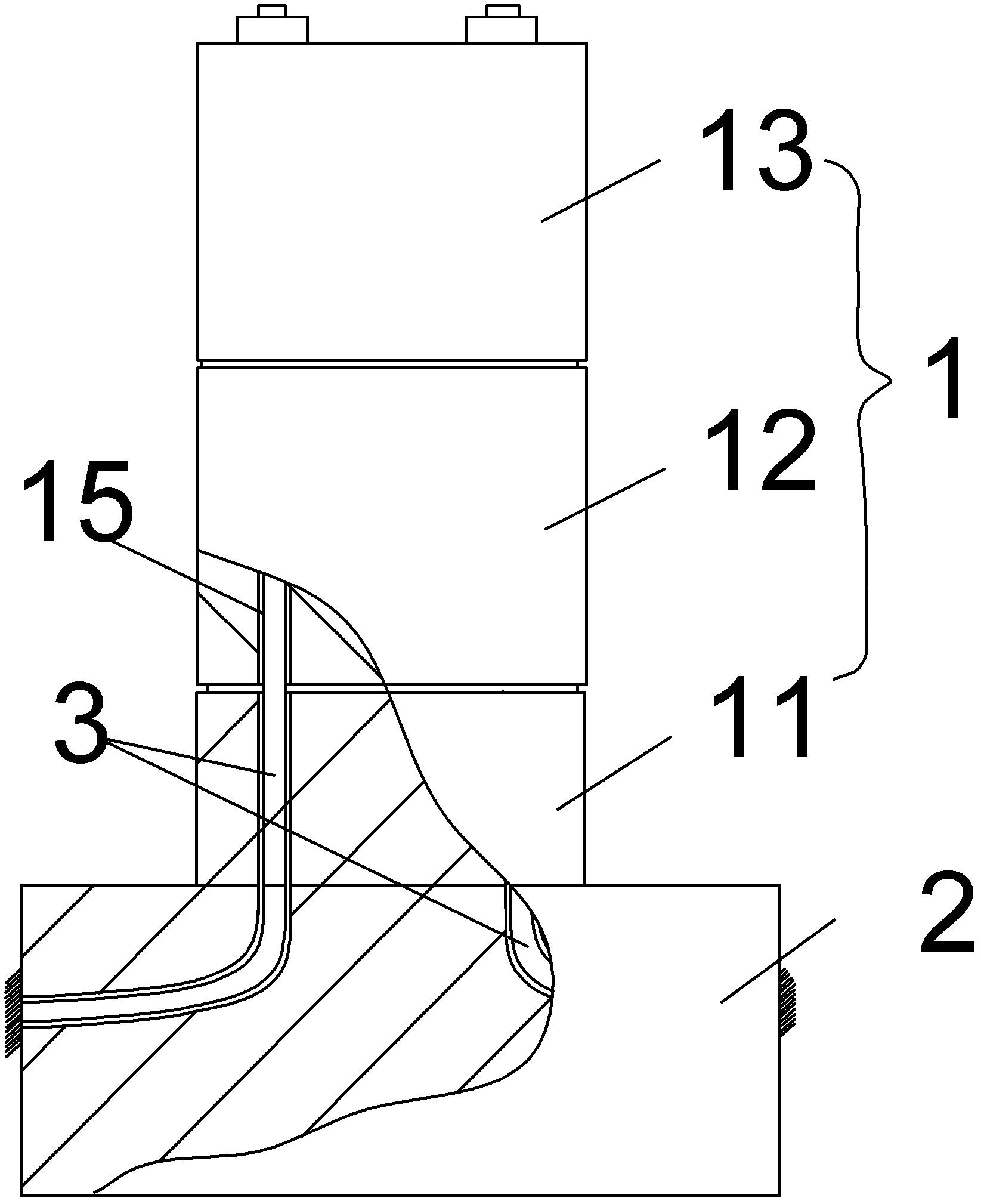

[0028] Such as image 3 As shown, a specific embodiment of the inclined-tensioned prefabricated assembled column cap structure of the present invention includes two major parts, the column 1 and the cap 2, which are fixedly connected to form the column cap structure.

[0029] The column 1 is composed of several prefabricated column segments 11, 12, 13 and so on. Each prefabricated column segment is a reinforced concrete component, which is prefabricated in batches in advance according to the design requirements in the prefabricated yard and transported to the construction site. In the present invention, each prefabricated column segment 11 , 12 , 13 is provided with a positioning through hole 15 .

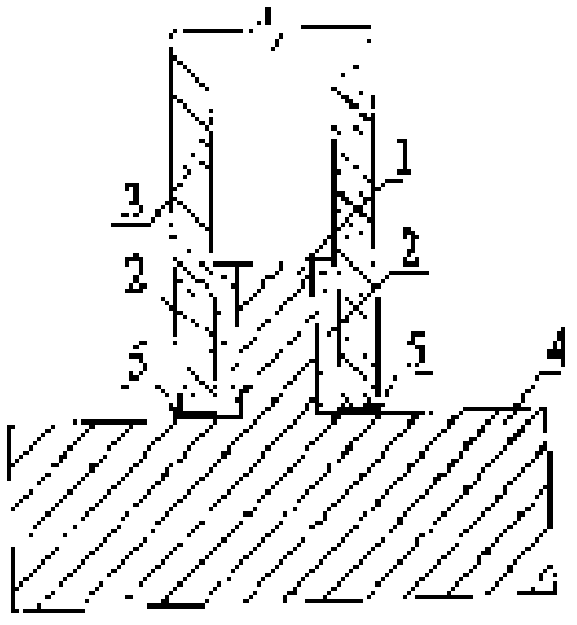

[0030] A prestressing component 3 is anchored in the bearing platform 2 , and the prestressing component 3 is obliquely arranged in the bearing platform 2 and penetrates through the top surface and the side surface of the bearing platform 2 .

[0031] The positioning through hole...

Embodiment 2

[0039] The assembly and positioning process of the inclined-tensioned prefabricated assembled column cap structure of the cap of the present invention is used to realize the positioning between the prefabricated column segment and the cap during the installation process of the cap inclined-tensioned prefabricated assembled column cap structure. Accurate positioning of prefabricated column segments with each other includes the following steps:

[0040] Step 1, refer to image 3 As shown, the prestressed component 3 is fixedly arranged on the platform 2 .

[0041] The prestressed component 3 is a prestressed steel strand, which is obliquely penetrated and arranged between the top surface and the side surface of the platform 2 . Specifically, the prestressed component 3 is anchored on the side of the platform 2 .

[0042] The special feature of the present invention is that the prestressing component 3 also serves as a positioning component.

[0043] Step 2, hoisting the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com