Detecting device and detecting method for evenness of fuel cell bipolar plate

A detection device, fuel cell technology, applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of low assembly pressure, can not reflect the flatness of bipolar plates, can not truly reflect the flatness of bipolar plates, etc. Inexpensive, true test results, and the effect of a large test range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following examples can enable those skilled in the art to understand the present invention more fully, but do not limit the present invention in any way.

[0036] Taking the metal bipolar plate as an example, the device and testing method provided by the present invention will be further described.

[0037] A fuel cell bipolar plate flatness detection device, the detection device includes a console 12, a press and a tested component, the tested component includes an upper end plate 10, a lower end plate 6, a tested bipolar plate 7 and an MEA8, the detection device It also includes carbon paper dummy electrodes 9;

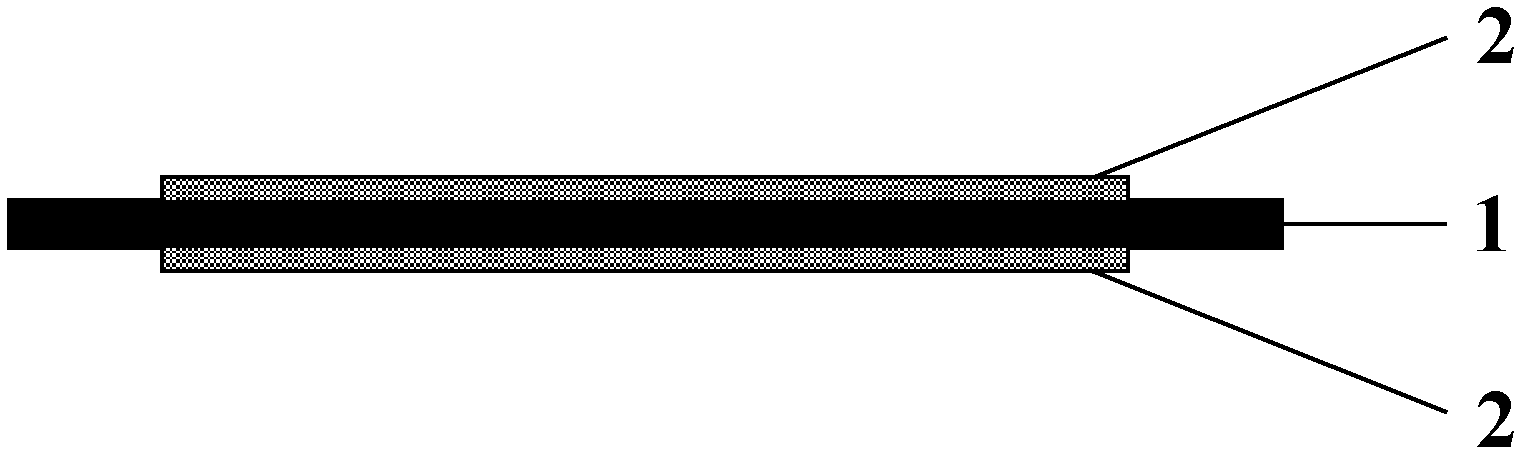

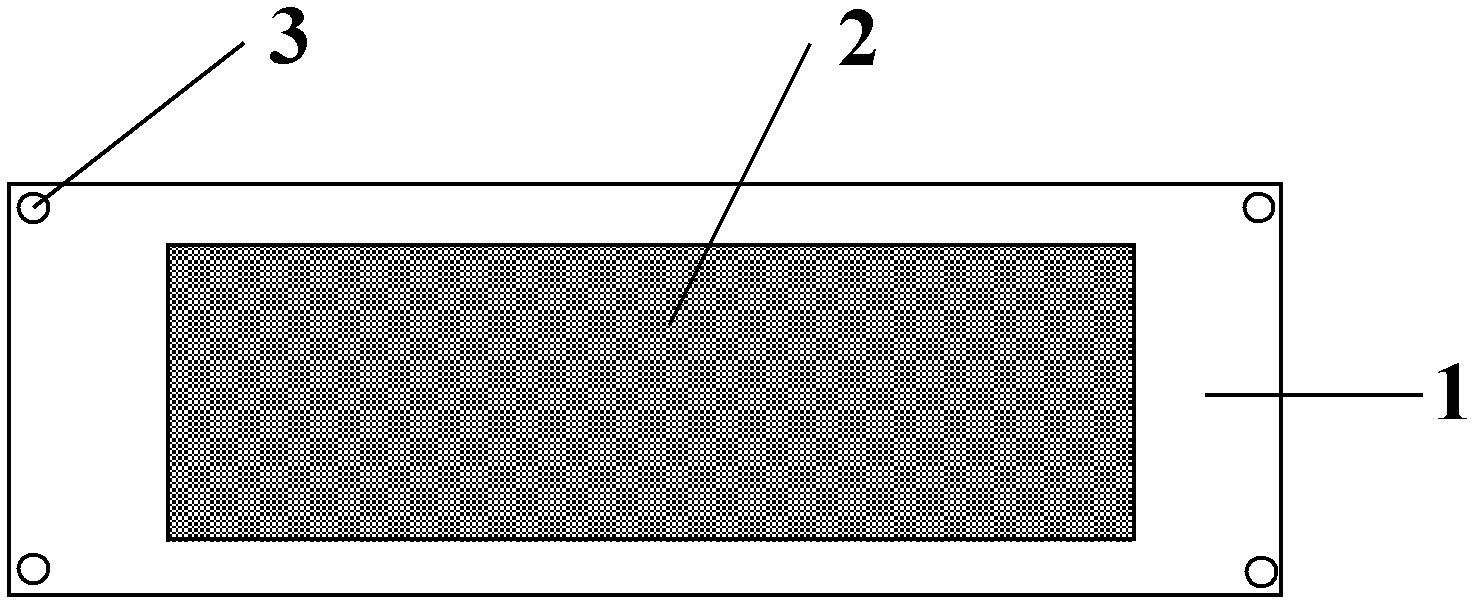

[0038] Wherein, carbon paper dummy electrode 9 is made up of carbon paper 2 clamping white stick paper 1 (as figure 1 shown); the size of white stick paper 1 is the same as MEA8, and the thickness is 0.07-0.1mm; the size of carbon paper 2 is the same as that of MEA effective area 11, and the thickness is 0.05-0.1mm;

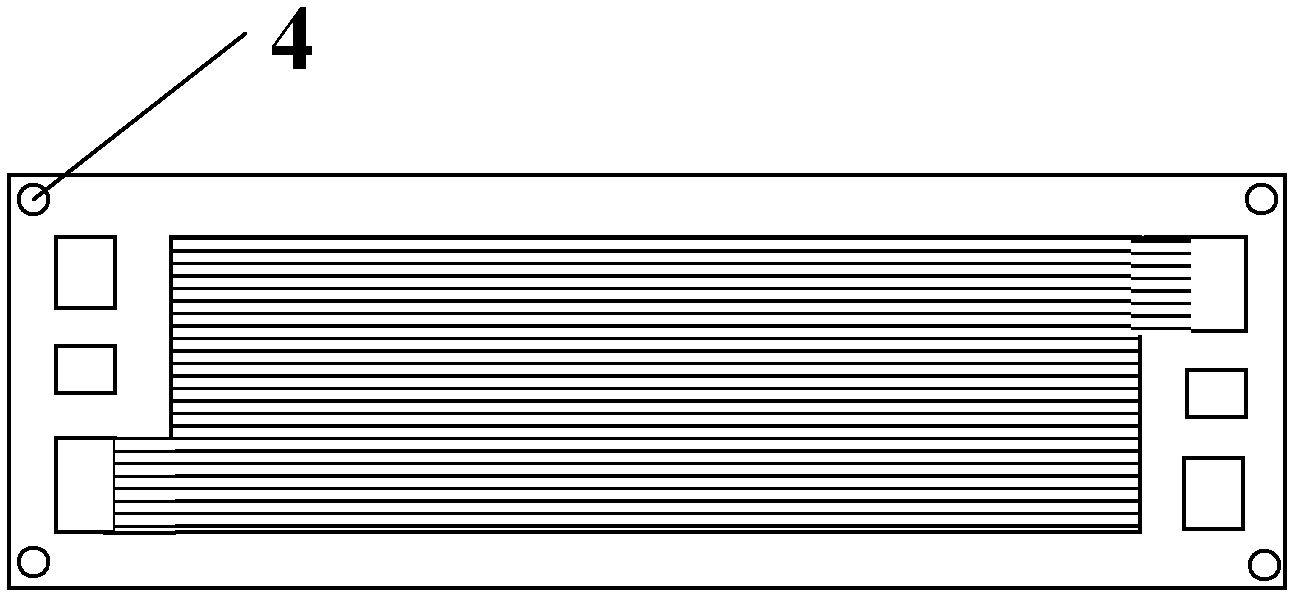

[0039] The positions of the four co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com