Flat panel television reliability test method

A flat-panel TV and reliability technology, applied in the field of flat-panel TV reliability test, can solve the problems of high cost and low reliability test efficiency, and achieve the effect of solving high cost, low solving efficiency and improving reliability level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

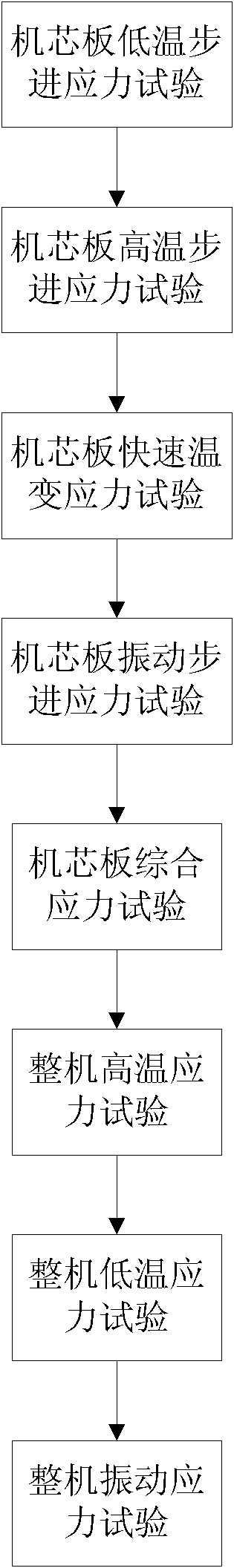

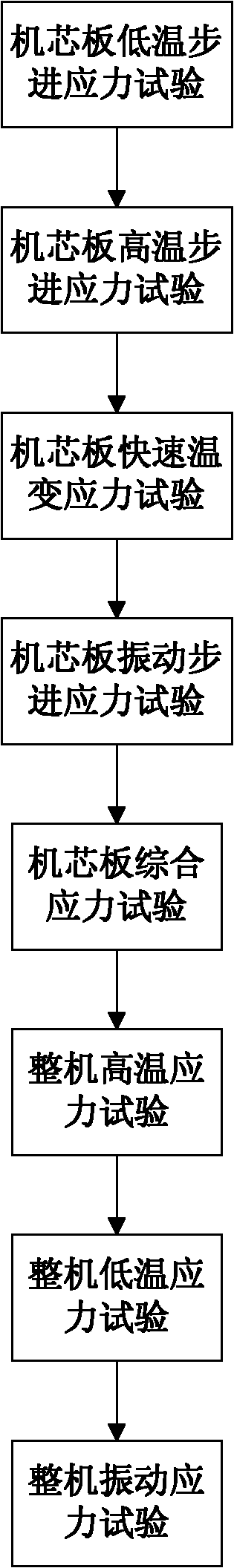

[0038] Such as figure 1 The methods for the reliability test of the flat-panel TV shown include the reliability test of the TV core board and the reliability test of the whole machine. The reliability test of the core board includes:

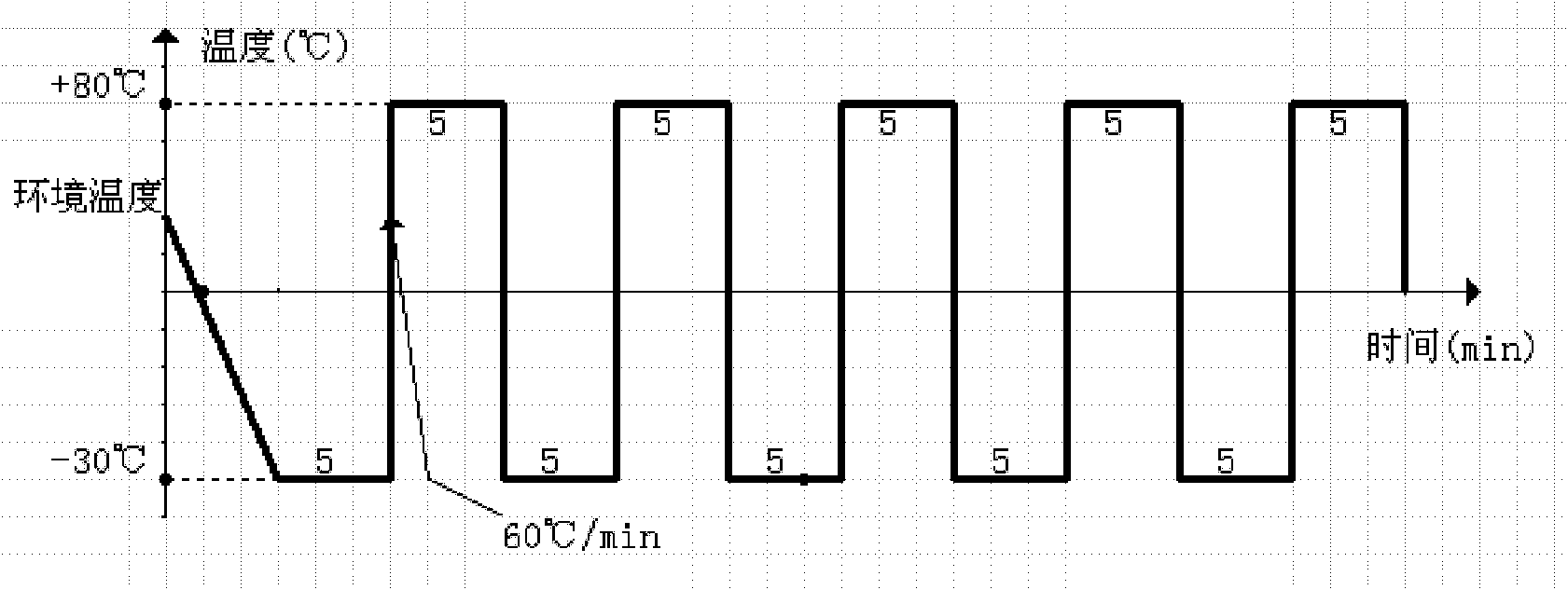

[0039] Temperature stress test:

[0040] a. The core board of the flat-panel TV is placed separately in the strengthened test bench to carry out the low-temperature step stress test. Extend the connection line between it and the power board, remote control board, screen and other components. The length of the connection line is 1.2 meters to 1.5 meters to increase the attenuation stress of the DC voltage and the signal on the screen.

[0041] Starting from 0°C, the temperature gradually decreases to -40°C. The test temperature points are 0°C, -20°C, -32°C, -35°C and -40°C in chronological order, and each test temperature point lasts for 10 minutes. The core board is subjected to temperature stress test;

[0042] b. Place the core board of the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap