Multi-sectional rejecting device and control method thereof

A rejection device, multi-stage technology, applied in electrical program control, program control in sequence/logic controllers, sorting, etc., can solve problems affecting production efficiency, potential safety hazards, and bottles falling on the chain path, etc. To achieve the effect of convenient operation and maintenance, low dumping rate and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

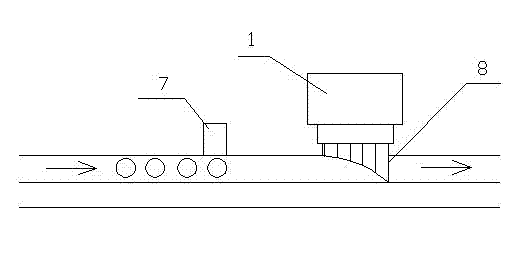

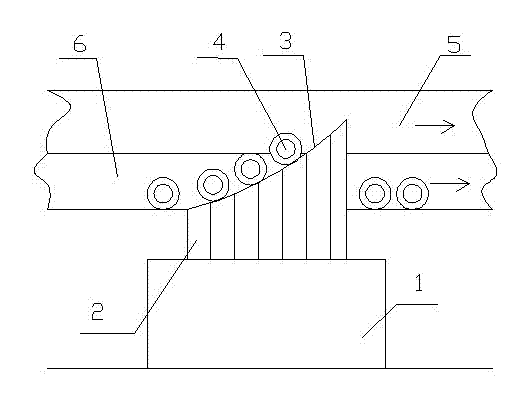

[0015] figure 2 It is a structural schematic diagram of the multi-stage rejecting device of the present invention. It can be seen from the figure that the multi-stage rejecting device includes a rejecting module 1 and a rejecting device 8. The rejecting device 8 is composed of a plurality of rejecting fingers 2. The rejecting module 1 has a plurality of cylinders. A plurality of air cylinders respectively drives a plurality of rejecting fingers 2 of different lengths to realize the rejecting effect. Multiple rejecting fingers 2 are closely arranged from short to long according to the conveying direction of the chain. The front end 3 of the rejecting finger adopts a uniform acceleration arc design. After all the rejecting fingers 2 are in motion, the smooth movement from the conveying chain 6 to the rejecting chain 5 is just completed. transition. In order to meet different bottle types, a lifting adjustment device is designed to make the rejected bottles run smoothly. At the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com