Die insert fixing structure

A technology for fixing structures and inserts, which is applied to forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as insert installation problems, and achieve the effect of increasing adjustment space and improving flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

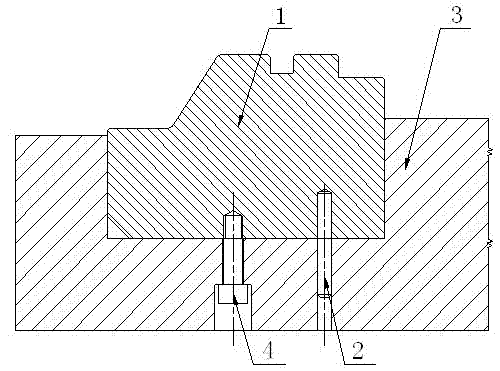

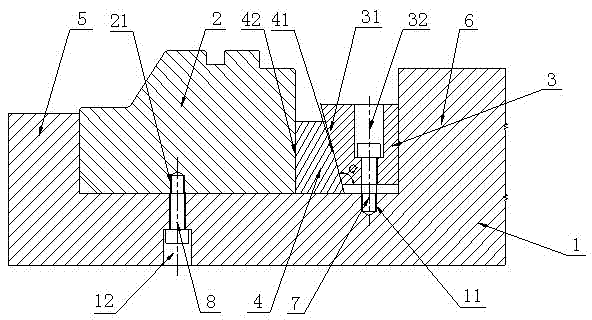

[0019] Such as figure 2 As shown, the mold insert fixing structure of this embodiment includes a mold base 1, an insert 2, a first wedge 3 and a second wedge 4 with a flat bottom surface; the mold base 1 is provided with a protrusion for blocking the movement of the insert 2 The first stopper 5 and the protruding second stopper 6 for blocking the movement of the first wedge 3, the first stopper 5 and the second stopper 6 are respectively arranged on both sides of the predetermined installation position of the insert 2; The mold base 1 is provided with a first threaded hole 11 between the second stopper 6 and the predetermined installation position of the insert 2; the first wedge 3 is provided with a first inclined side 31 with an inclination angle α greater than 90° and is used for matching with the The first threaded hole 11 cooperates with the through hole 32 for installing the bolt in the first threaded hole 11, and the side 33 opposite to the first inclined side 31 of th...

Embodiment 2

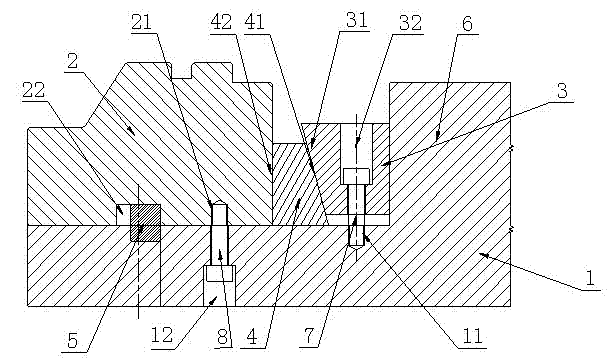

[0023] Such as image 3 As shown, the difference from Embodiment 1 is that the first stopper 5 of this embodiment is arranged at the predetermined installation position of the insert 2 , and the bottom of the insert 2 is provided with a recess 22 for cooperating with the first stopper 5 . This method is suitable for the case where the predetermined installation position of the insert 2 is located at the edge of the mold base 1 , and the movement of the insert 2 can be prevented by the cooperation of the first stopper 5 and the recess 22 of the insert. The length of the recess 22 is greater than the length of the first stopper 5 to facilitate the adjustment of the position of the insert 2 within a certain range.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com