Device and method for evaluating accuracy of prism-free distance measurement of total station

An evaluation device and total station technology, which is applied to measurement devices, instruments, etc., can solve the problems of strong reflection, reduced ranging accuracy, and inability to guarantee the accuracy of the prism-free ranging mode, and achieve the effect of reasonable use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

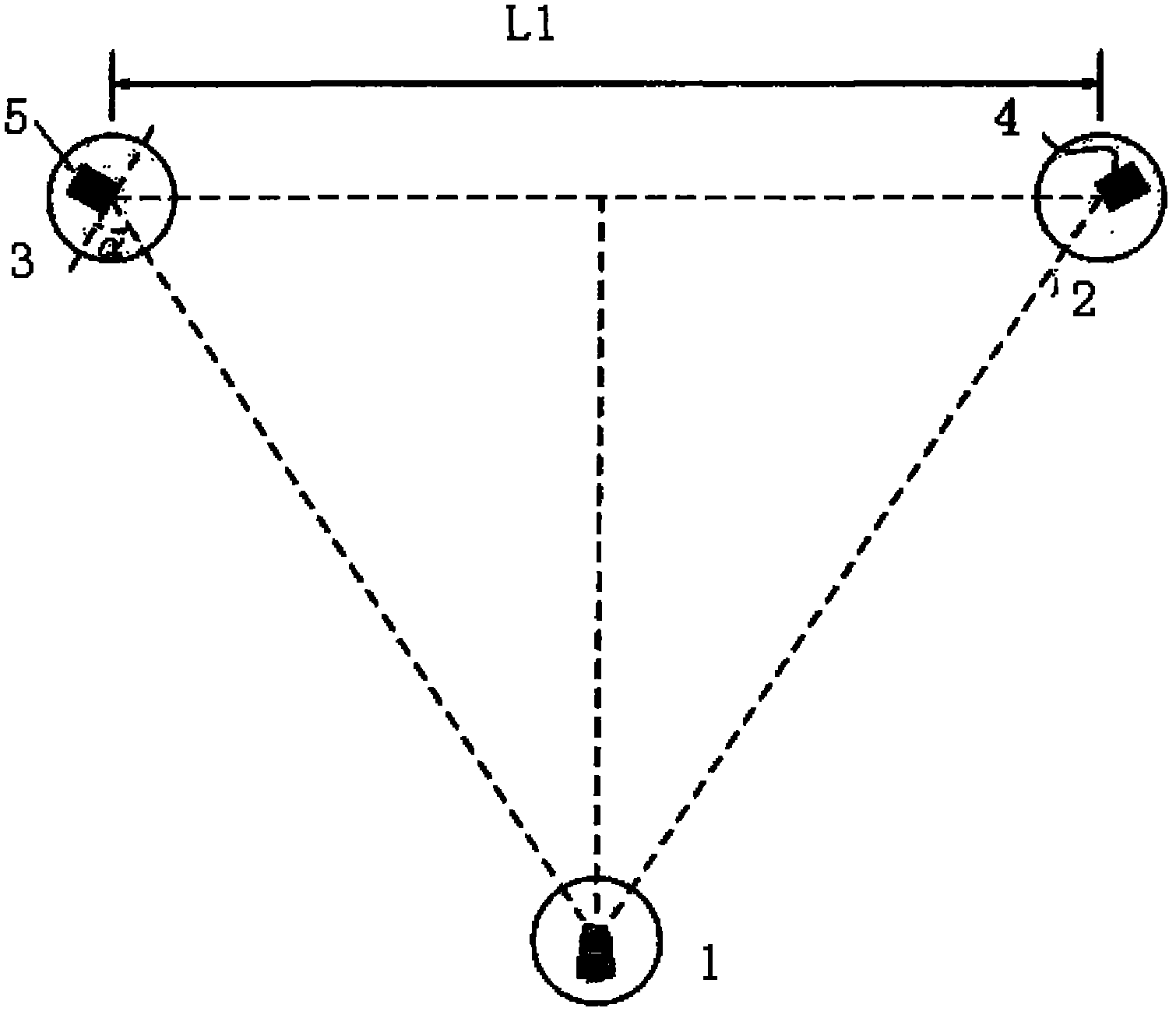

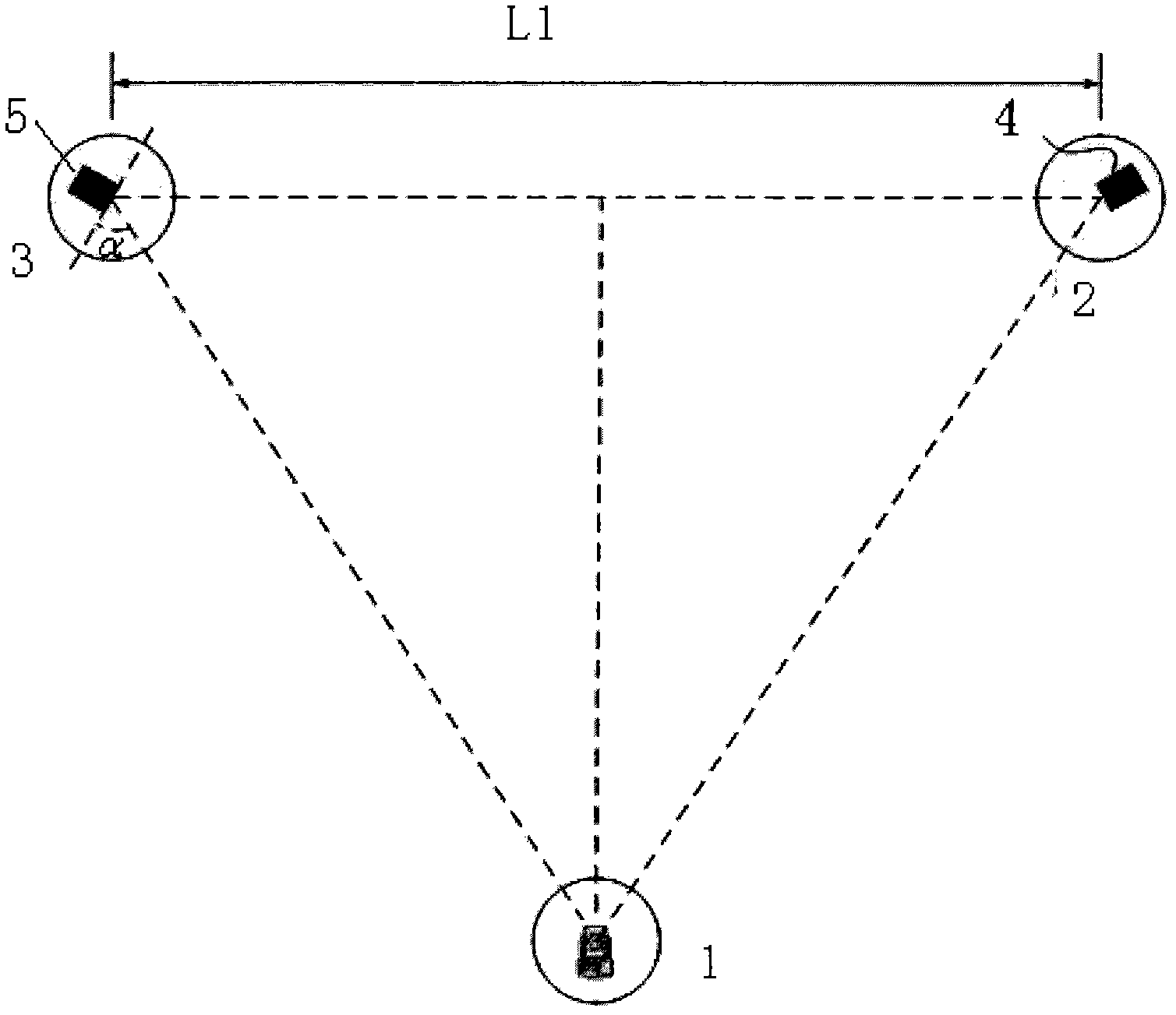

[0020] Such as figure 1 As shown, the total station 1 is in the non-prism mode, and the ranging accuracy of the total station 1 is evaluated using an evaluation device including two fixed platforms and a standard length measuring tool (not shown). The two fixed platforms are rotatable fixed platforms with scales, which are respectively the first fixed platform 2 and the second fixed platform 3. Specifically, there are circumferential scales on the two fixed platforms, and the fixed platforms can be By manually adjusting the rotary scale dial, or a motor-driven scale disc. The first positioning part 4 is fixed on the first fixed platform 2 by a clamp, and likewise, there is a second positioning part 5 on the second fixed platform 3, and the second positioning part 5 can be fixed to the second fixed platform. On platform 3, the positioning parts on the two fixed platforms can manually adjust the angle or automatically select the appropriate rotation position and rotation angle ...

Embodiment 2

[0026] As a modification of Embodiment 1 of the present invention, the same content of Embodiment 2 and Embodiment 1 will not be repeated, and the first fixed platform and the second fixed platform can be arranged on a horizontal sliding rail with scales, thereby facilitating the second Accurate adjustment of the distance between the first fixed platform and the second fixed platform, the positioning components on the fixed platform are not limited to cylinders, as long as the incidence surfaces of the first positioning component and the second positioning component are regular and easy to determine their center points The shape of the total station can be replaced by the first positioning part and the second positioning part and the different sample substances to be tested on the total station, and the length is measured at different incident angles and incident distances, and the total station can be obtained. The measurement accuracy evaluation data of the instrument.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com