Detecting method and detecting system for detecting rectangular metal bars

A technology of metal bars and detection methods, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, can solve the problems of low detection efficiency, high operator quality requirements, visual fatigue, etc., to achieve rapid detection, improve detection efficiency, The effect of ensuring the detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

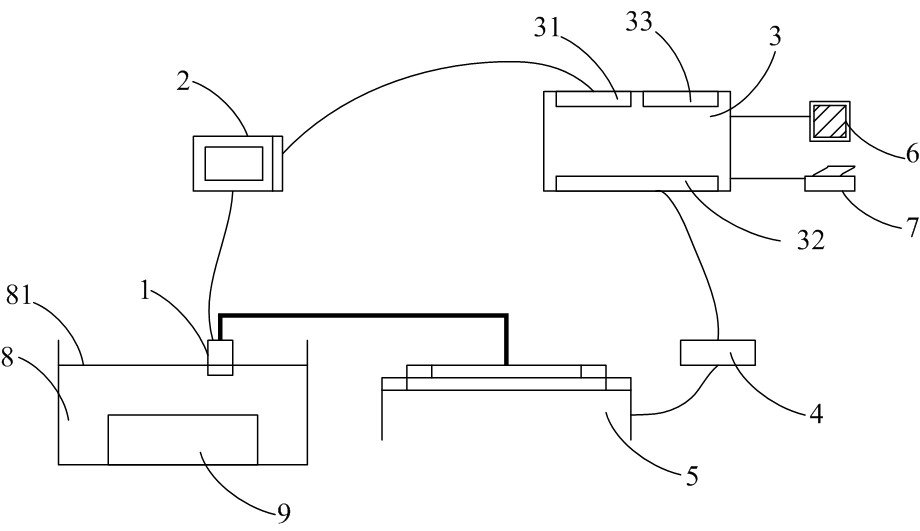

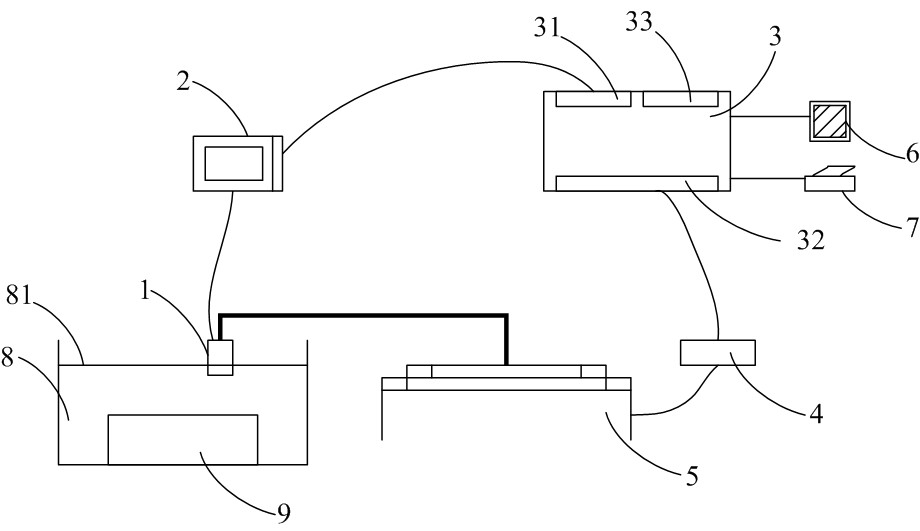

[0031] see figure 1 In the connection diagram of the detection system, the rectangular metal bar 9 to be tested is placed in the water tank 8 and submerged under the liquid surface 81, and the probe 1 is installed on the scanning mechanism 5, and is set opposite to the rectangular metal bar 9 to be tested The ultrasonic flaw detector 2 is connected with the probe 1, and the industrial computer 3 is equipped with an ultrasonic acquisition card 31, a serial interface 32 and an input device 33, and the ultrasonic acquisition card 31 is connected with the ultrasonic flaw detector 2 for receiving the signal of the ultrasonic flaw detector 2 , and send a driving signal through the serial interface 32; the driving device 4 is connected to the serial interface 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com