Special live-axle hub motor for electric vehicle

A technology of electric vehicles and axle wheels, applied in the field of electric vehicles, can solve problems such as inconvenient mass production and daily maintenance, reduced reliability of electrical connections, loss of installation bases, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

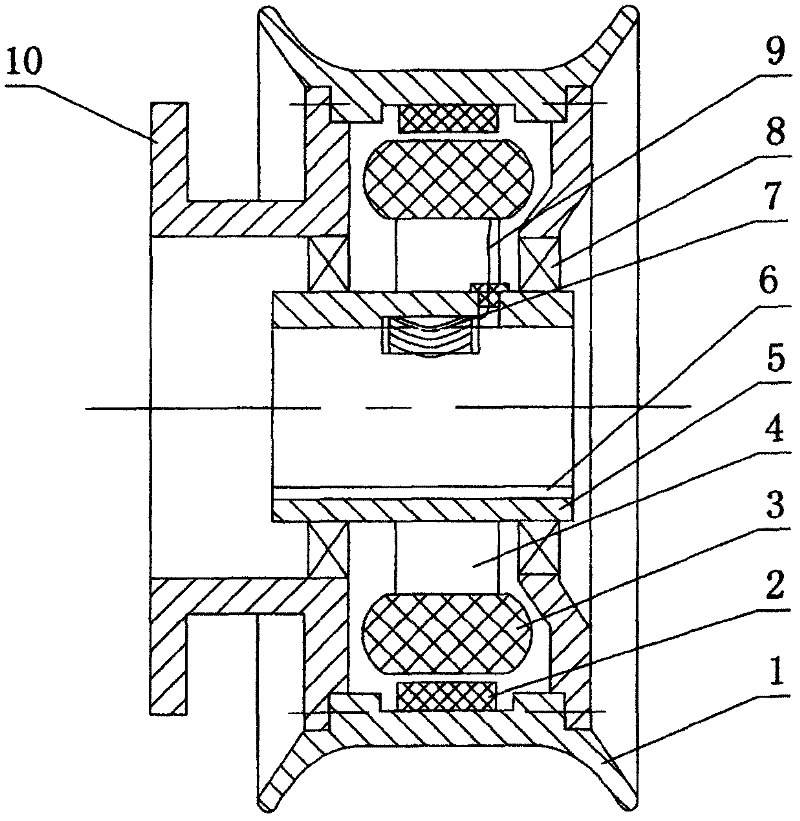

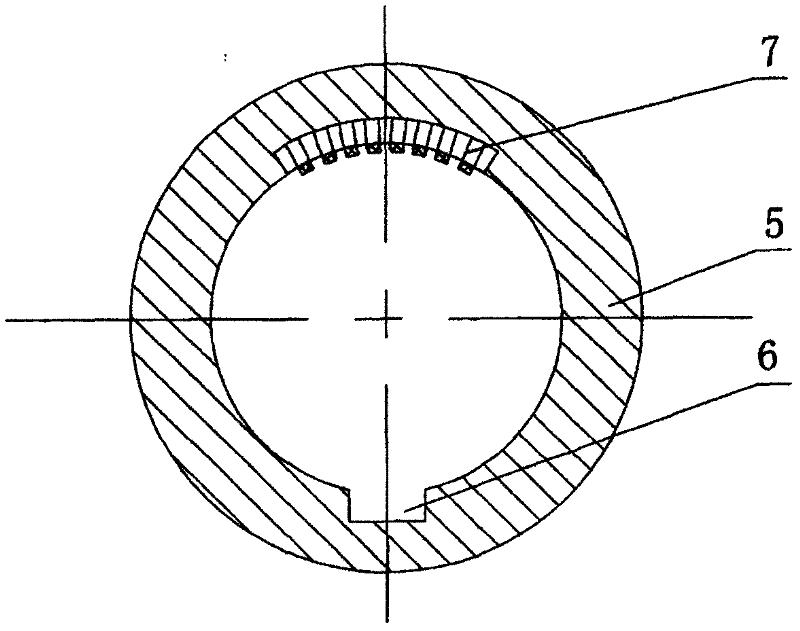

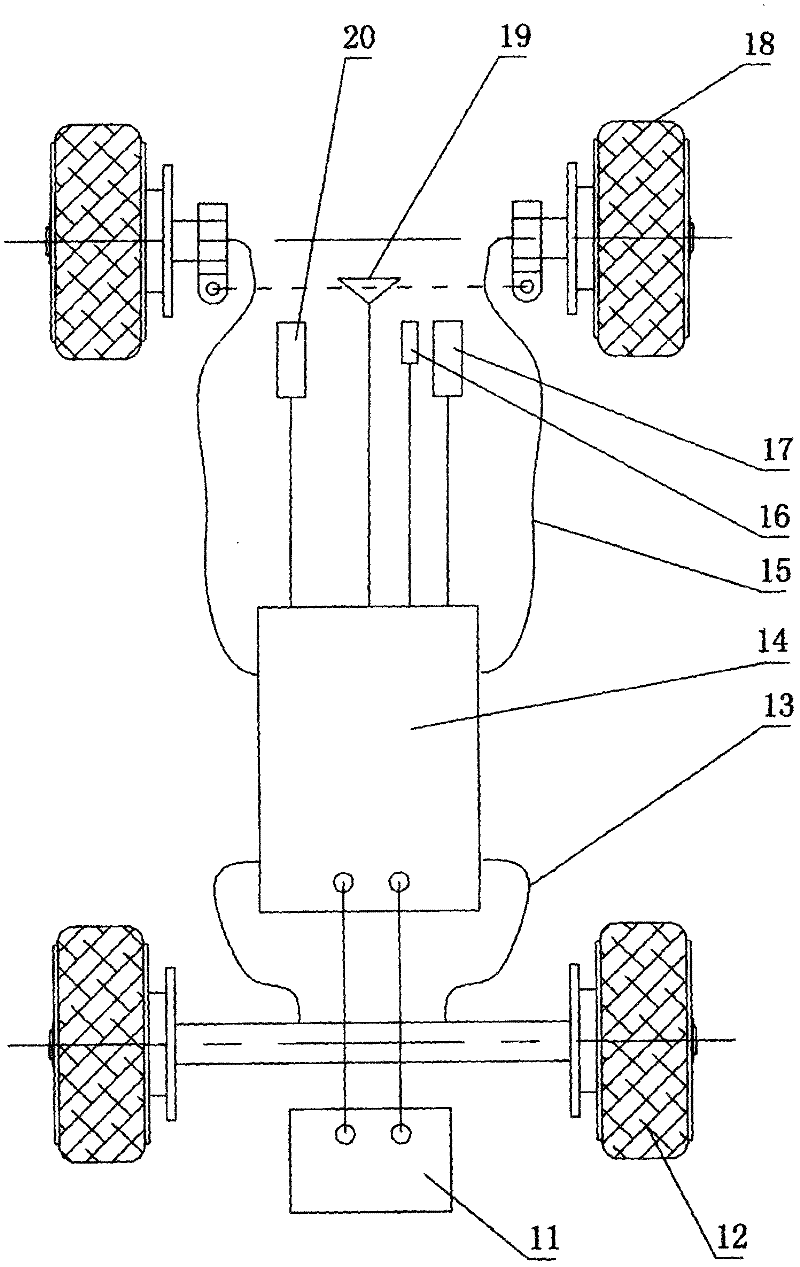

[0014] figure 1 , figure 2 The shown live shaft hub motor includes a hollow casing 5, and a stator is fixed on the outer wall of the hollow casing. The stator includes a coil 3 and a stator bracket 4 installed on the hollow casing. On the outer walls of the hollow casing on both sides of the stator Bearing 8 is also housed respectively, and the hub rotor 1 that is positioned at stator periphery and double as motor housing is installed on the bearing 8, and there is magnetic steel 2 on the inwall of hub rotor. The inner wall of the hollow sleeve is provided with an axially penetrating keyway 6, and the middle section of the inner wall of the hollow sleeve is provided with a sinking groove at the position opposite to the keyway. The wire hole on the casing wall, the sinker is embedded with an elastic electrical connection terminal 7, the motor coil lead wire 9 passes through the wire hole and is electrically connected to the elastic electrical connection terminal 7, and the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com