Protective Cap Assembly with Leak Detection Capability for Pressure Valves

A technology of pressure valve and cap assembly, which is used in valve devices, engine components, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

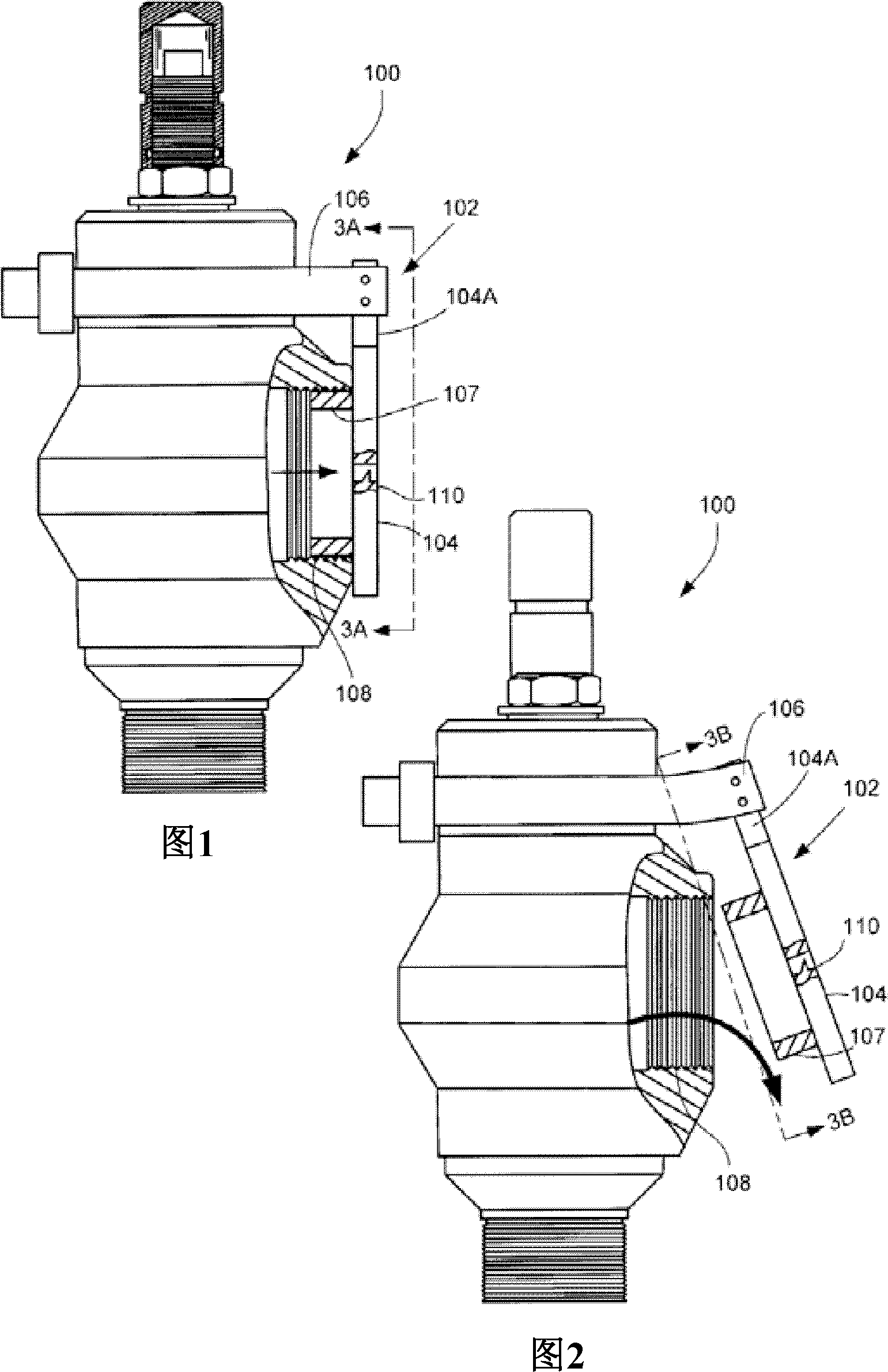

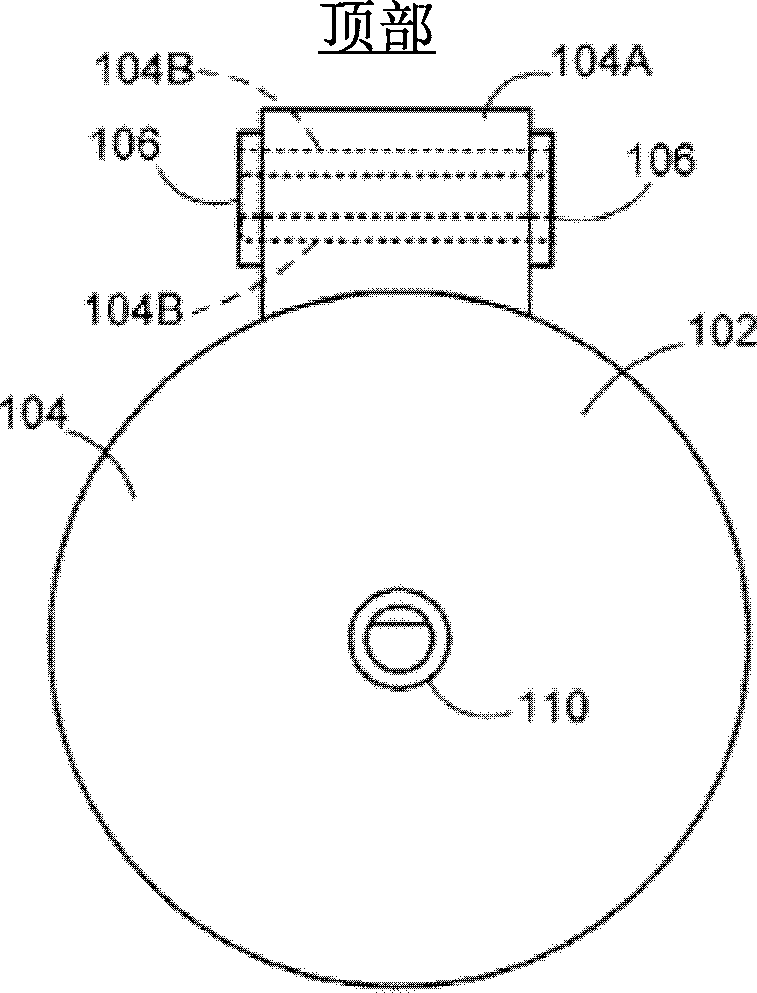

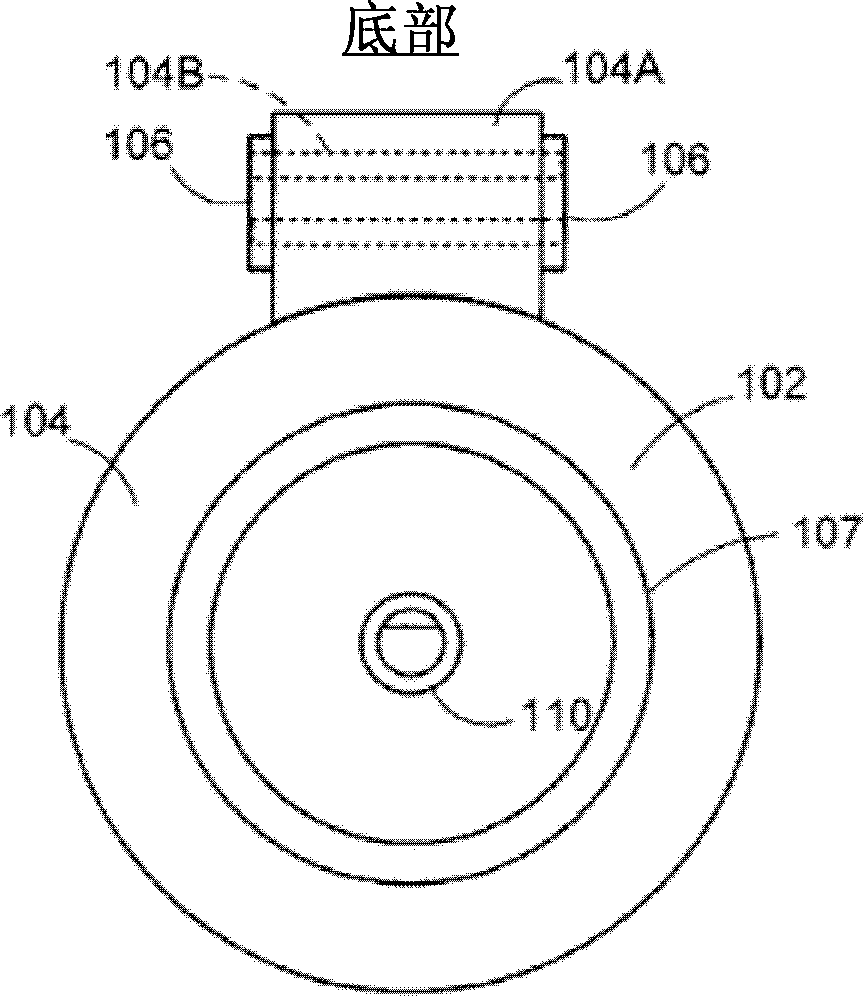

[0041] Without limitation, embodiments of the present invention generally relate to an environmental protection cap assembly for providing human sensory cues to indicate fluid flow in a pressurized fluid system.

[0042] As described below, in some embodiments, the cap assembly is configured to cover a discharge conduit downstream of a pressure valve for discharging fluid to ambient air. The cap assembly provides a cue by providing an audible and / or visual cue that fluid flow through the valve has a low level of leakage. In some embodiments, a whistle may be used to provide an audible cue to indicate a leak; in other embodiments, an LED may be used to provide a visual cue to indicate a leak.

[0043] figure 1 Pressure relief valve 100 is shown provided with an environmental protection cap assembly 102 associated therewith. The pressure relief valve 100 is of the normally closed type so that during normal processing, upstream pressurized fluid (such as gas or liquid) is pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com