Welding wire machine and anti-oxidation structure thereof

A technology of anti-oxidation and wire welding machine, applied in welding equipment, non-electric welding equipment, electrical components, etc., can solve the problems of large nitrogen consumption, difficult replacement and maintenance of the ignition rod, etc., to reduce the consumption, facilitate maintenance, improve The effect of wire bond efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to describe in detail the technical content, structural features, achieved objectives and effects of the present invention, the following is a detailed description in conjunction with the embodiments and accompanying drawings.

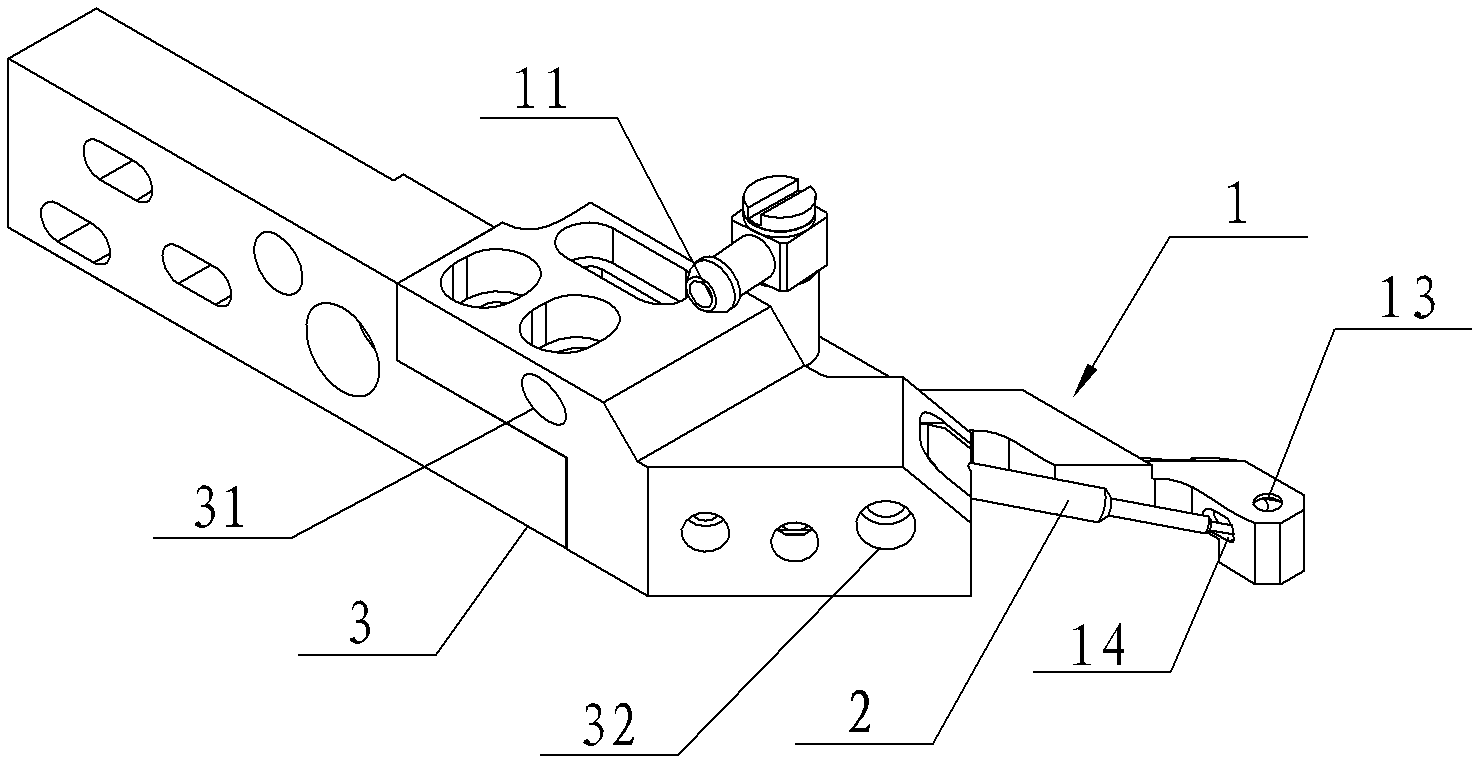

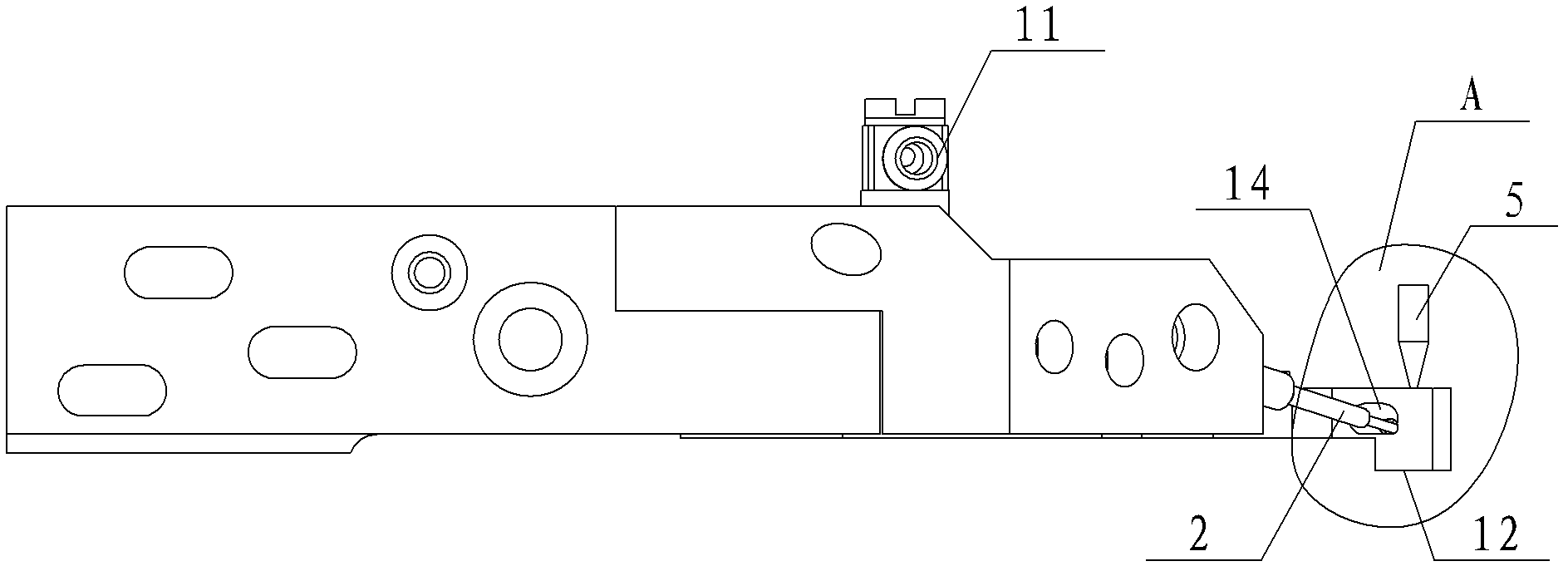

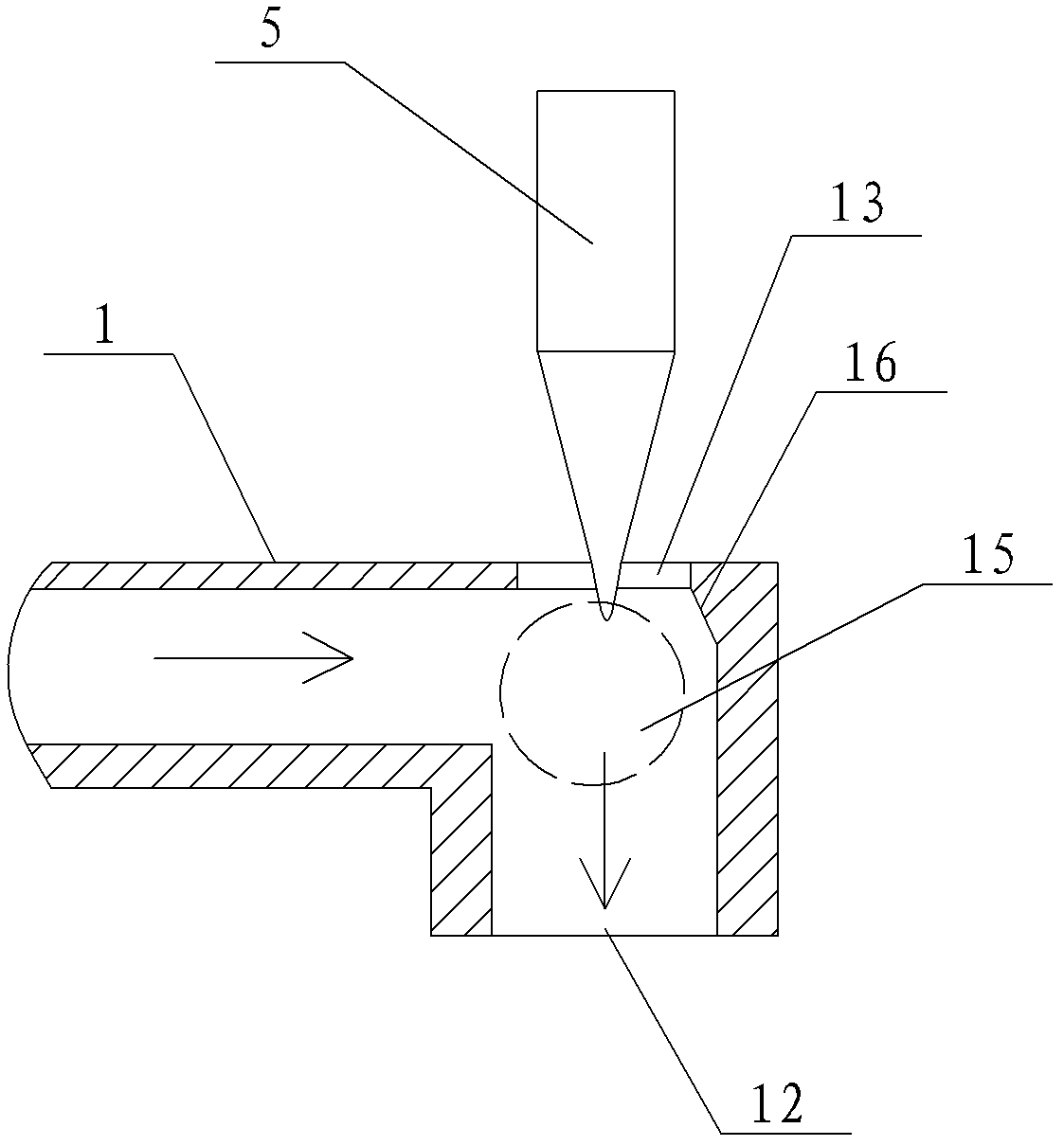

[0023] See Figure 1 to Figure 3 , The present invention provides an anti-oxidation structure for a wire bonding machine, comprising a gas circulation pipe 1, a firing rod 2 independent of the gas circulation pipe 1, and a firing rod fixing seat for fixing the firing rod 2 3. The gas circulation pipe 1 has an air inlet 11 and an air outlet 12. A burning ball zone 15 is provided in the gas circulation pipe 1 near the gas outlet 12, which corresponds to the gas circulation pipe 1 of the burning ball zone 15. The walls are respectively provided with a first through hole 13 for the welding wire of the ball to be burnt to extend into the burning area 15 and a second through hole 14 for the end of the firing rod 2 to extend into the burning are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com