Built-in type anti-theft packaging bottle

A packaging bottle, built-in technology, applied in the field of built-in anti-theft packaging bottles, can solve the problem of easy counterfeiting or prying, no separation from the bottle cap, and no traces of opening left on the anti-theft ring and bottle cap, which cannot be achieved Anti-theft effect and other issues, to achieve the best anti-theft effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

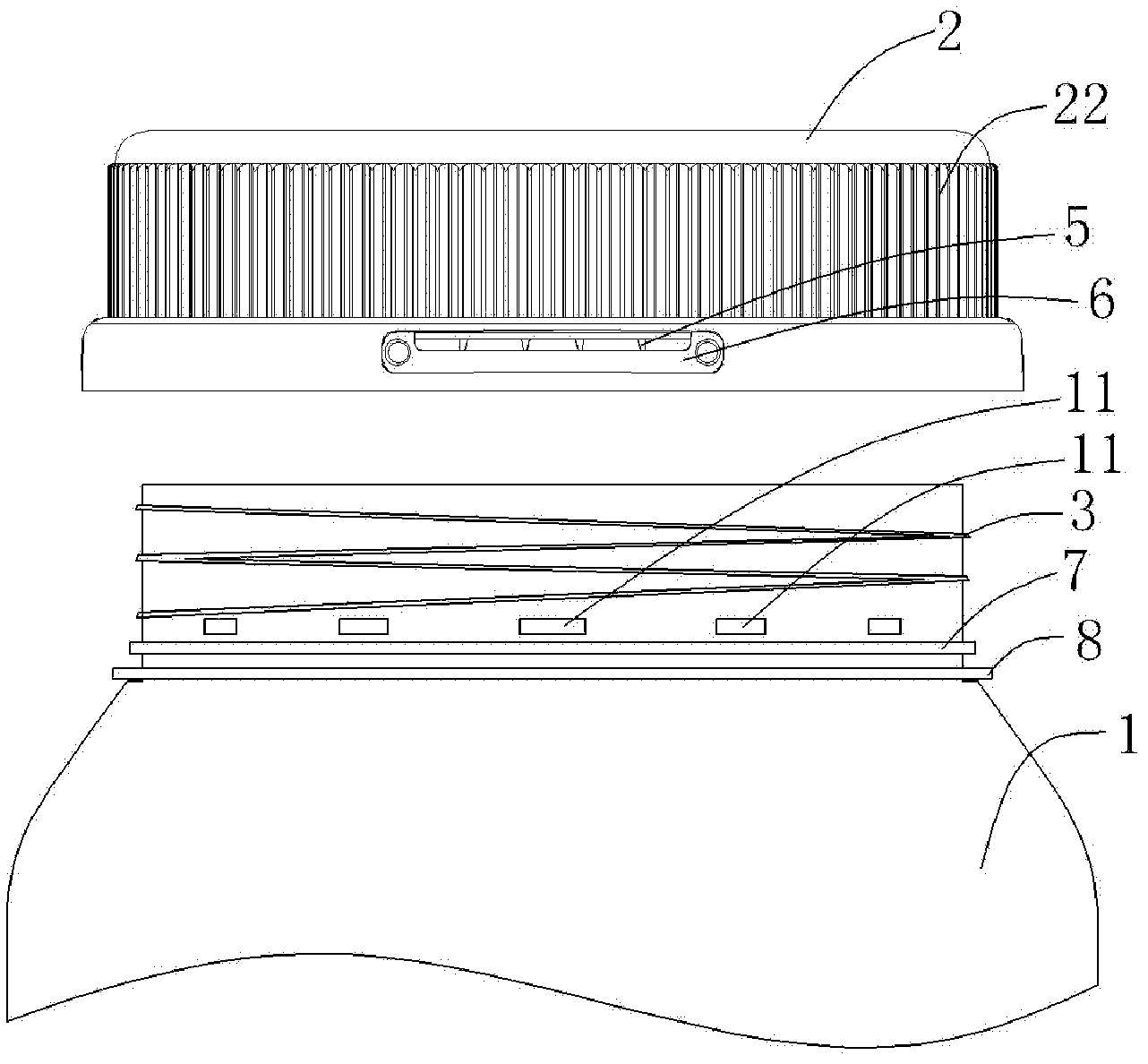

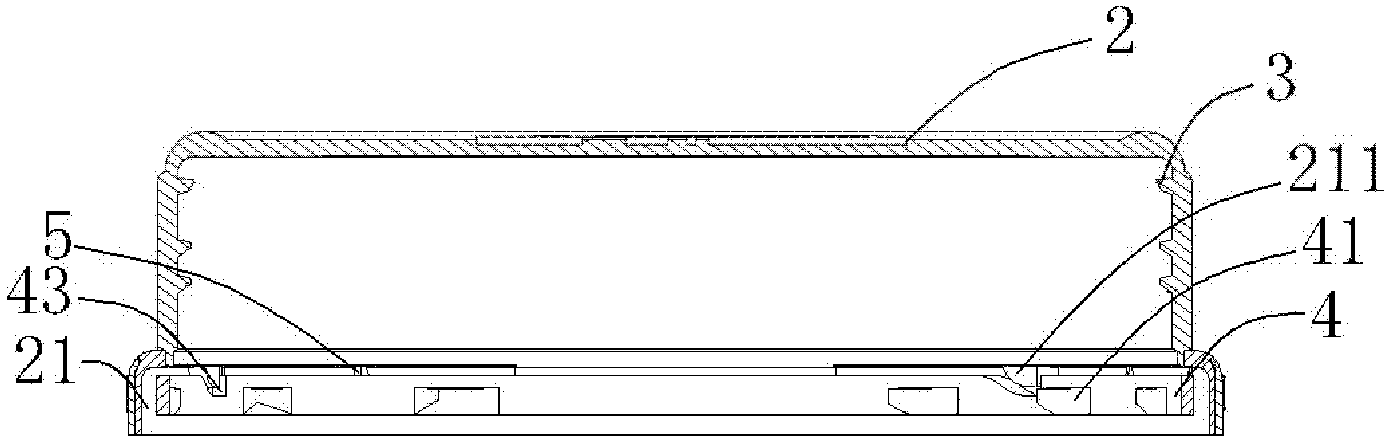

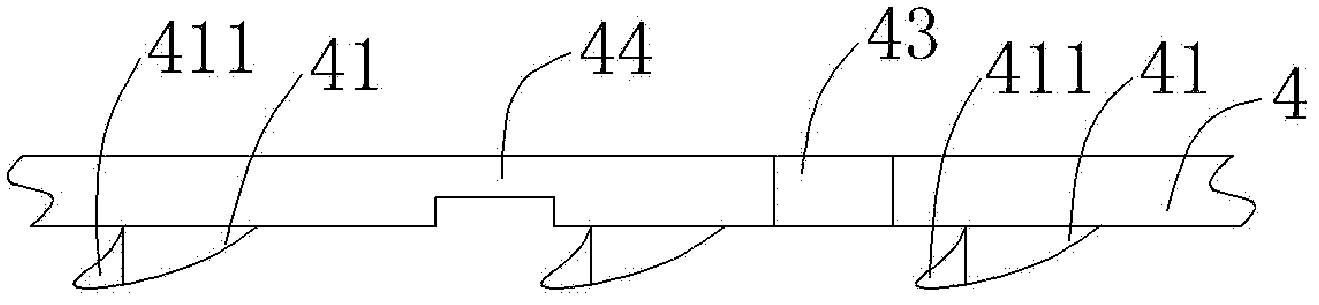

[0025] The present invention will be further elaborated below in conjunction with accompanying drawing, wherein, the direction of the present invention is with figure 1 as standard.

[0026] Such as figure 1 , figure 2 and image 3 As shown, the first embodiment of the built-in anti-theft packaging bottle of the present invention includes a bottle body 1, a bottle cap 2, an anti-theft ring 4 and a connecting rib 5, and the corresponding positions of the bottle mouth outer wall of the bottle body 1 and the inner wall of the bottle cap 2 Threads 3 that cooperate with each other are respectively formed, and the lower side of the thread 3 of the bottle mouth is formed with a stop ring 8 that restricts the rotation of the bottle cap 2 to the installation position, and the outer surface of the bottle cap 2 is formed with longitudinal teeth that are convenient for tightening and opening the bottle. 22, the inner wall of the lower side of the bottle cap 2 is recessed outwards to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com