Air source heat pump system for providing direct high temperature air

An air source heat pump and hot air technology, applied in heat pump, fluid heater, drying gas arrangement, etc., can solve the problem of inability to obtain high temperature hot air, avoid a significant increase in power consumption, solve condensation temperature, and improve the effect of hot air temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: Eight-color printing machine heating transformation project:

[0026] The original status of the project: a 1050 mm wide eight-color gravure printing machine, because the exhaust gas contains a large amount of organic solvents, it is impossible to use the air source heat pump to heat the circulating air. Can not meet the requirements, so the electric heating tube heating method is used. The electric heating power is 30KW per color, divided into three levels, the first level is 15KW, the second level is 9KW, the third level is 6KW, a total of 240KW, and the eight-color printing temperature requirements are 60℃-62℃, 60℃-62℃, 63 ℃-66℃, 80℃-83℃. 63°C-66°C, 70°C-73°C, 72°C-75°C, 80°C-83°C. When the ambient temperature is 32°C (the same below), the power consumption for printing, drying and heating is 191°C per hour.

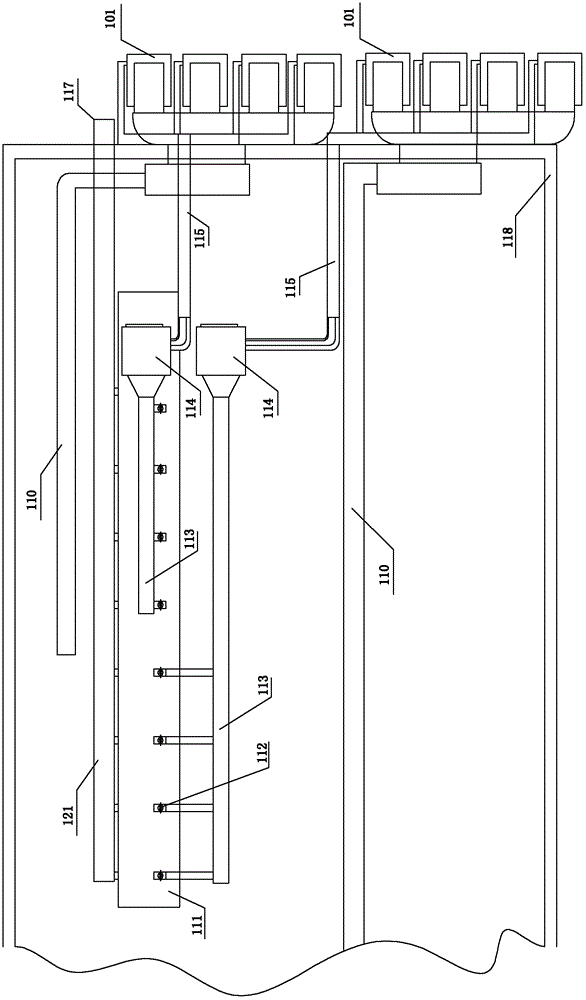

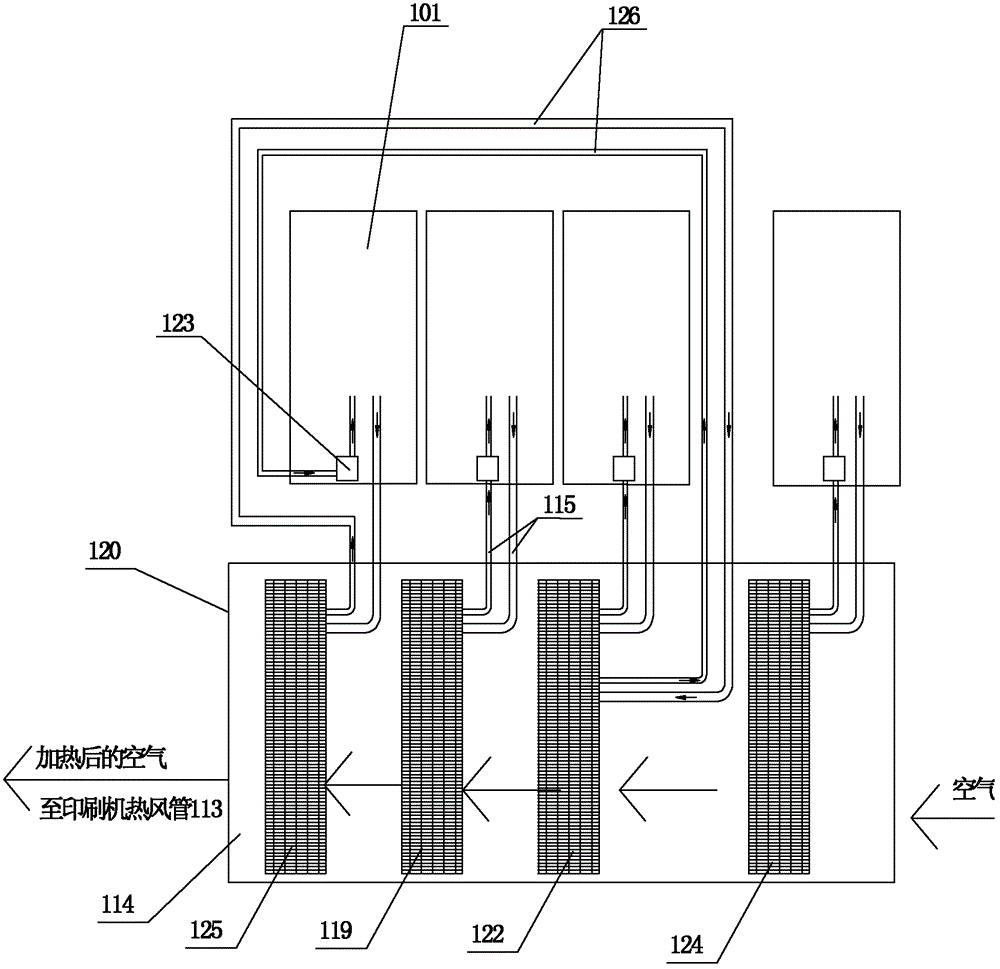

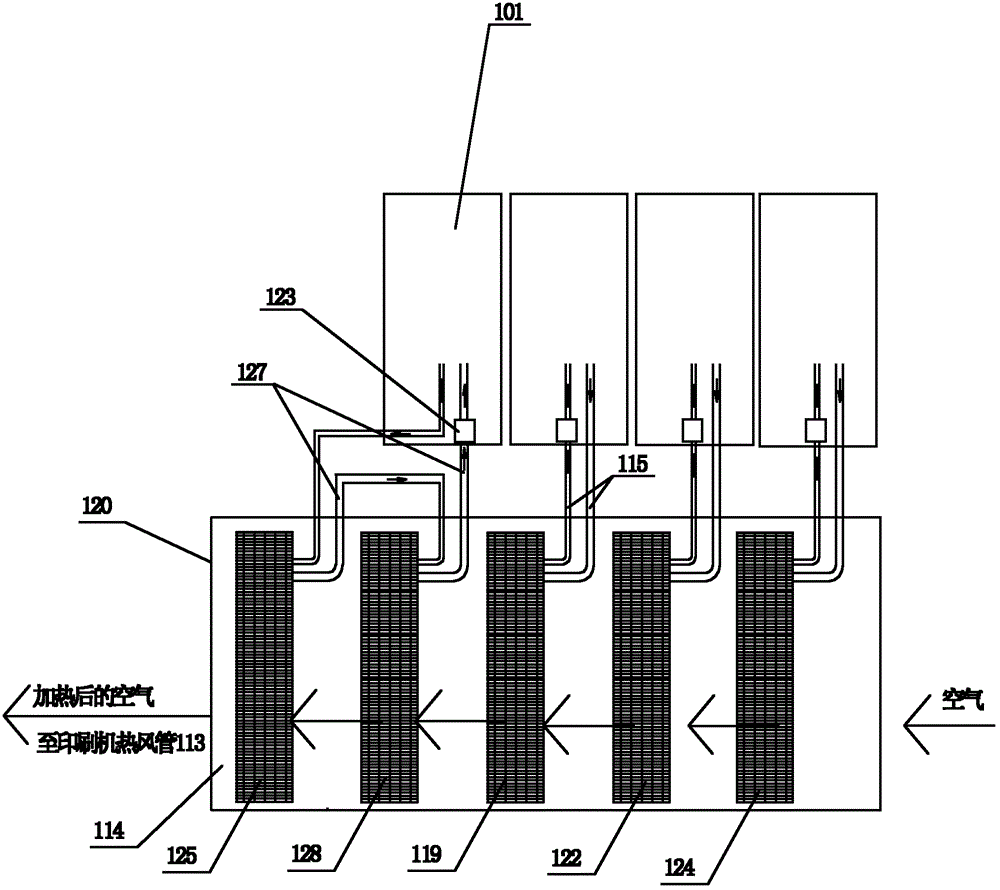

[0027] Situation after adopting technical scheme of the present invention to transform: see figure 1 , 2 , reflecting a specific structure of t...

Embodiment 2

[0032] Example 2: Dry compound machine heating transformation project:

[0033] The original status of the project: one 1050mm dry compound machine, the wind speed of the three air inlets is 2000m 3 About / h, the high temperature zone is required to be 80°C-83°C, the medium temperature zone is 71°C-74°C, and the low temperature zone is 62°C-65°C. Because the exhaust gas contains organic solvents, the air source heat pump cannot be used for circulating air heating, and the air source heat pump is used to heat the air with direct current air, and the air temperature cannot meet the requirements, so the electric heating tube heating method is used. The power of the electric heating tube in the high temperature zone of the dry compound machine is 70KW, the power of the electric heating tube in the medium temperature zone is 55KW, the power of the electric heating tube in the low temperature zone is 50KW, and the total electric heating power is 175KW. When the ambient temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com