Simulation modeling method of electro-hydraulic servo valve based on Modelica language

An electro-hydraulic servo valve, simulation modeling technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problem that servo valves are difficult to analyze hydraulic servo systems, difficult to modify and replace components, and basic components cannot be reused, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

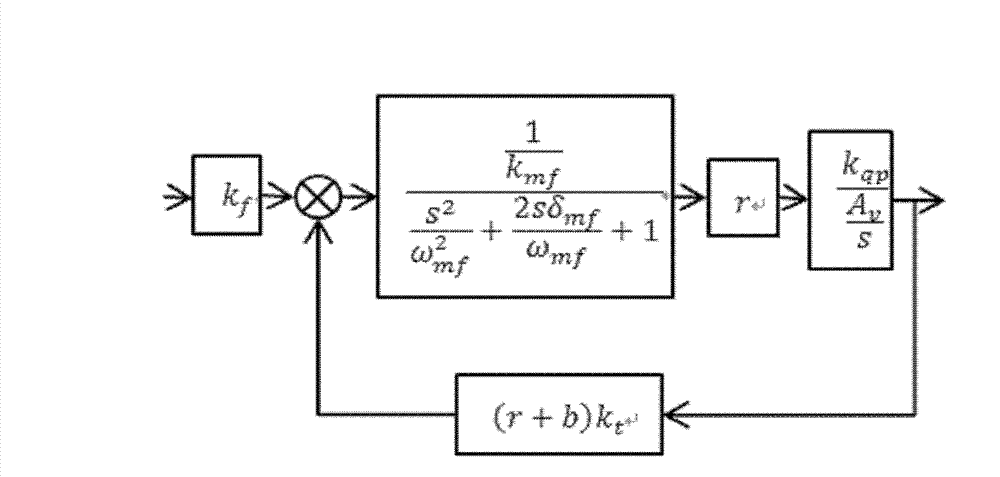

[0036] as attached figure 1 As shown, it is the traditional electro-hydraulic servo valve analysis method. The analysis method using the block diagram cannot faithfully reflect the structural characteristics of the electro-hydraulic servo valve. It is inconvenient to modify the parameters, and it is not easy to substitute into the servo system for overall design and analysis.

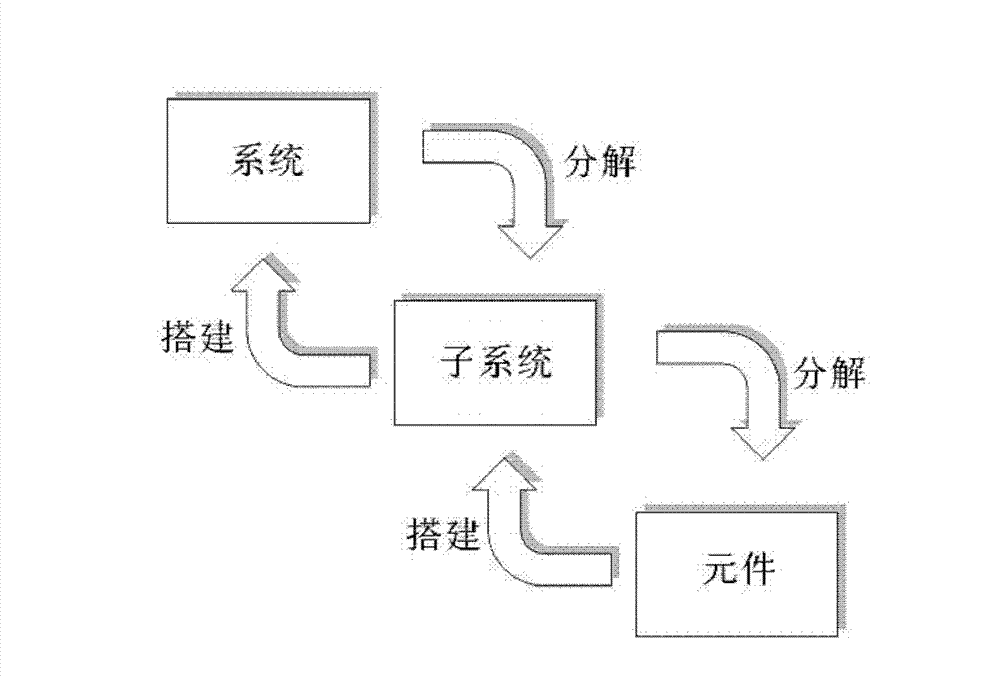

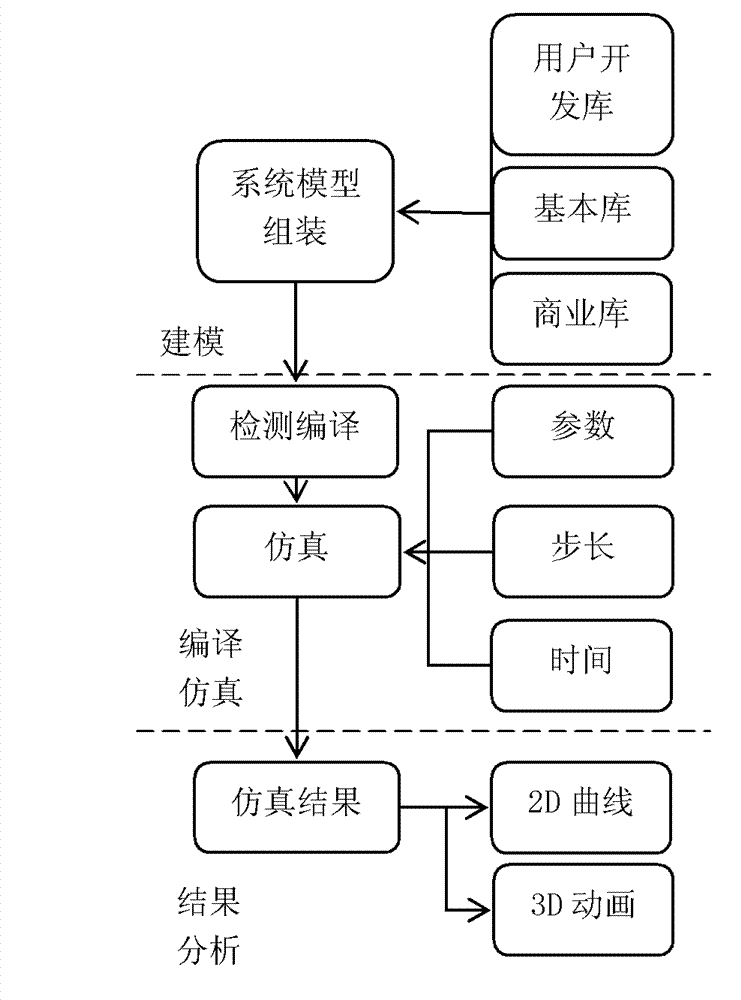

[0037] as attached figure 2 , image 3 shown, with figure 2 Based on the basic analysis principle of the present invention, aiming at the object-oriented nature of the Modelica language, the system is decomposed in a targeted manner, and the system is built using the components that have been modeled. attached image 3 For the analysis process of the present invention, the completed electro-hydraulic servo valve model is compiled and simulated by setting simulation parameters, step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com