Method of producing harm-reducing cigarette filter

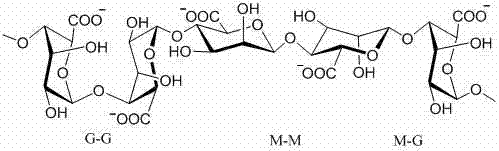

A technology for cigarette filters and filter rods, which is applied in e-liquid filter elements, tobacco, applications, etc., to achieve the effects of coordinated smoking, reduced release, and improved smoking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

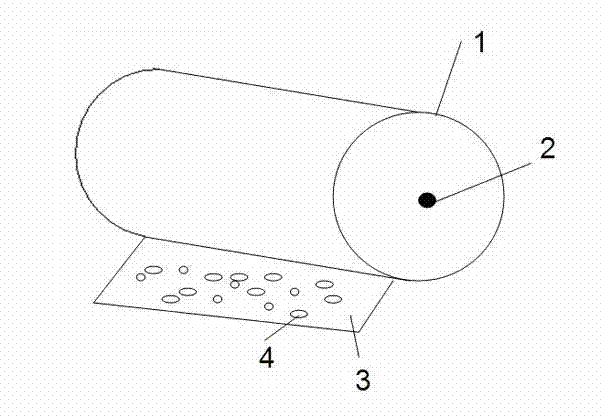

[0027] The seaweed fiber single yarn is prepared by drawing, coarse sand, and fine sand to produce a 40s single yarn. The single yarn adopts the rotor spinning process and is prepared into a seaweed fiber filament with a diameter of 1mm after being combined with 8 strands under the condition of a twist of 400 twists / m. After the acetate fiber is opened, the seaweed fiber bundle is pulled to the forming machine by the traction positioning device, and added to the center of the filter tip through the filter tip forming equipment, and the forming paper is made of ordinary forming paper to obtain a cigarette filter rod.

Embodiment 2

[0029] The seaweed fiber single yarn is drawn, coarse sand, and fine sand to prepare a 40s single yarn. The single yarn adopts the rotor spinning process, and the single yarn is prepared into a seaweed fiber with a diameter of 1.5mm after 12 strands under the condition of a twist of 400 twists / m. The tow is then prepared on a filter rod forming machine to obtain a cigarette filter rod; the forming paper is made of high-permeability forming paper to obtain a cigarette filter rod, and the air permeability of the forming paper is 12000CU.

Embodiment 3

[0031] The seaweed fiber single yarn is drawn, coarse sand, and fine sand to prepare a 40s single yarn. The single yarn adopts the rotor spinning process, and the single yarn is prepared into a seaweed fiber with a diameter of 1.5mm after 12 strands under the condition of a twist of 400 twists / m. tow;

[0032] Pull the seaweed fiber tow to the filter rod forming machine, add it to the center of the filter rod tow through the filter tip forming equipment, and become the filter rod tow containing the seaweed fiber tow;

[0033] Tobacco particles are crushed into 300 meshes, and evenly distributed on the forming paper, the weight of the used tobacco particles accounts for 5% of the dry weight of the forming paper; the forming paper is wrapped in the outer layer of the filter rod tow.

[0034] Using cigarette shredded tobacco, cigarette paper, tipping paper and filter sticks prepared by the above-mentioned method from Guangdong China Tobacco Industry Co., Ltd. A brand, under the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Air permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com