Method of producing cigarette filter containing absorbent materials

A technology of cigarette filter sticks and adsorption materials, which is applied in e-liquid filter elements, tobacco, applications, etc., to achieve the effects of improving filtration efficiency, safety and quality of smoking, and reducing the amount of release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

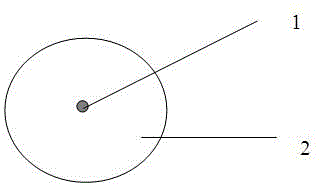

[0026] The seaweed fiber single yarn is drawn, coarse sand, and fine sand to prepare a 40s single yarn. The single yarn adopts the rotor spinning process, and the single yarn is prepared into a seaweed fiber with a diameter of 1.5mm after 12 strands under the condition of a twist of 400 twists / m. Tow: After the acetate fiber is opened, the seaweed fiber bundle is pulled to the forming machine by the traction positioning device, and added to the center of the filter tip through the filter tip forming equipment, and the forming paper is made of high permeability forming paper to obtain a cigarette filter rod.

Embodiment 2

[0028] Seaweed fiber filter rod combined with tobacco particle filter rod:

[0029] Preparation of seaweed fiber filter rod: the seaweed fiber single yarn is prepared by drawing, coarse sand, and fine sand to prepare 40s single yarn. The single yarn is prepared by rotor spinning process and 12 strands under the condition of twist 400 twist / m. Seaweed fiber tows with a diameter of 1.5mm are added to the center of the filter tip on the filter rod forming machine through the filter tip forming equipment, and the forming paper is prepared from ordinary forming paper to obtain a cigarette filter rod.

[0030] Preparation of the tobacco particle filter rod: dry and pulverize the tobacco particle into 300 meshes, and add it to the filter rod according to the mass content of 5% of the filter rod.

[0031] On the cigarette filter rod compounding machine, the seaweed fiber filter rod and the tobacco particle filter rod are compounded according to the length ratio of 0.5:0.5.

[0032] A...

Embodiment 3

[0034] Preparation of the tobacco particle filter rod: dry and pulverize the tobacco particle into 300 meshes, and add it to the filter rod according to the mass content of 5% of the filter rod. On the cigarette filter rod compounding machine, the ordinary filter rod and the tobacco particle filter rod are compounded according to the length ratio of 0.5:0.5. The ordinary filter rod is placed at the rear end, and a section containing tobacco particles is placed at the front end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com