industrial tools

A tool and industrial technology, applied in the direction of motor tools, manufacturing tools, signal transmission systems, etc., can solve problems such as screw connection failure, and achieve the effect of improving process reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

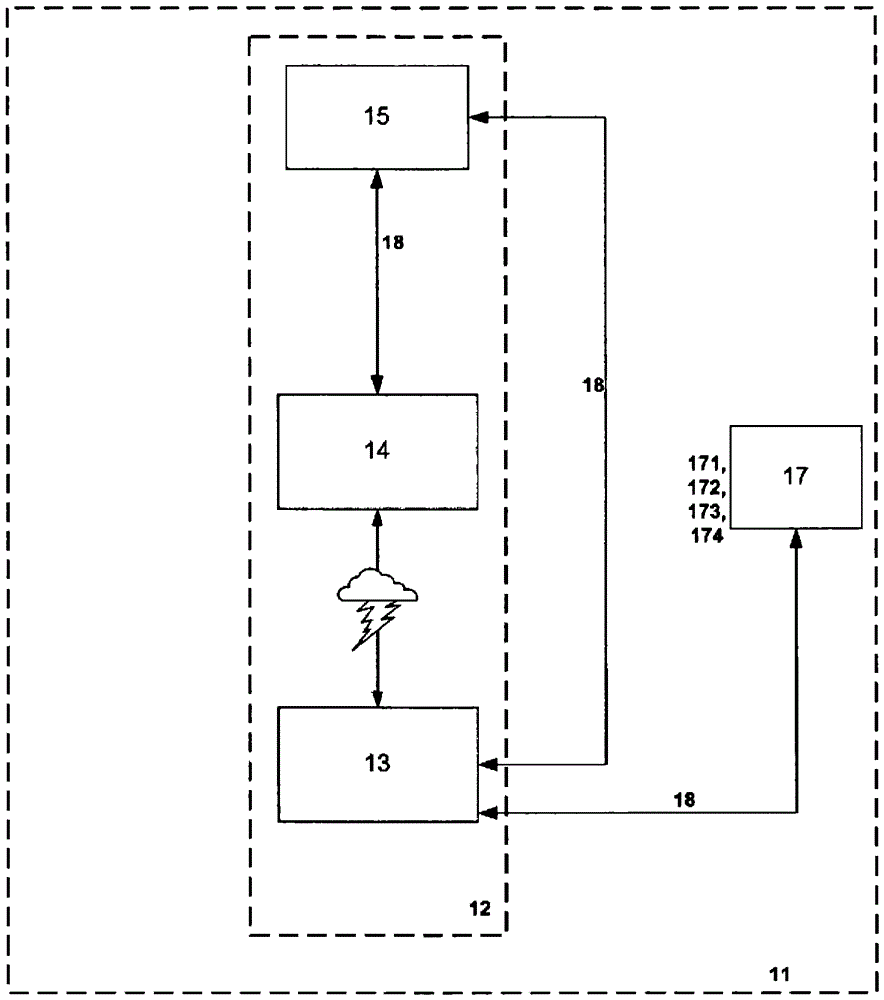

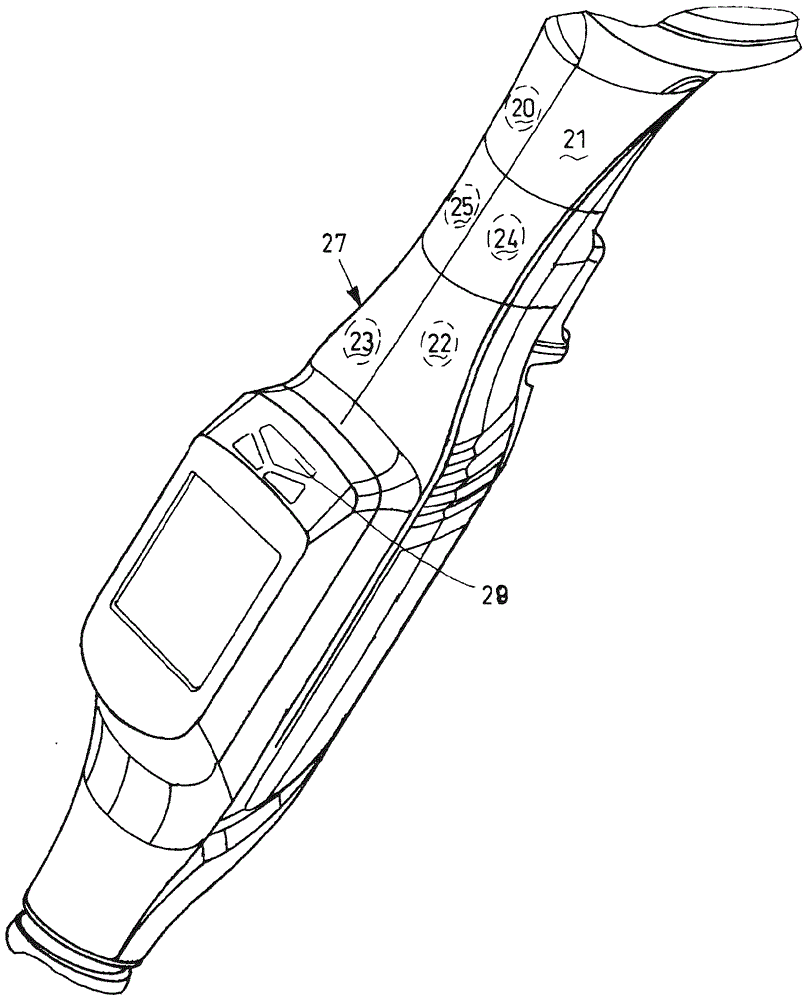

[0032] figure 1 A system for carrying out an automated industrial screwing process is shown, which has a device 17 and a screwing tool 13 . Said device 17 is a mobile phone with user-specific programs and usual components for configuring the tightening tool 13, such as a keypad, display screen etc. 171-174. Program 172 is designed in such a way that it takes place as a data exchange between a tool control (not shown) contained in tool 13 and a corresponding wireless module (not shown) also contained in tool 13 . The tightening tool is battery operated and includes standard data interfaces (WLAN, Bluetooth and similar). By means of the standard data interface, the tightening tool can be remotely controlled using so-called access points (Access Points) 14 which can be installed in the company area of the production plant.

[0033]The remote control takes place by means of a superordinate tightening process control unit. The access points 14 define the coverage area of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com