Tire bead wrapping apparatus

A technology of winding device and bead, applied in tires, other household appliances, household appliances, etc., can solve the problem of heavy labor load of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

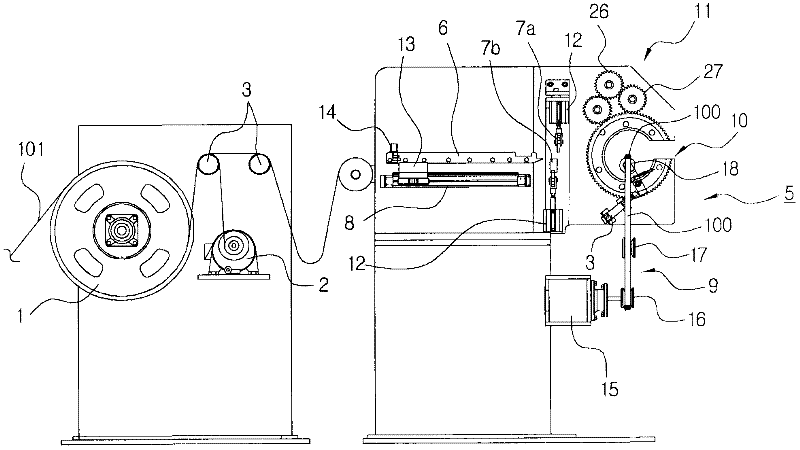

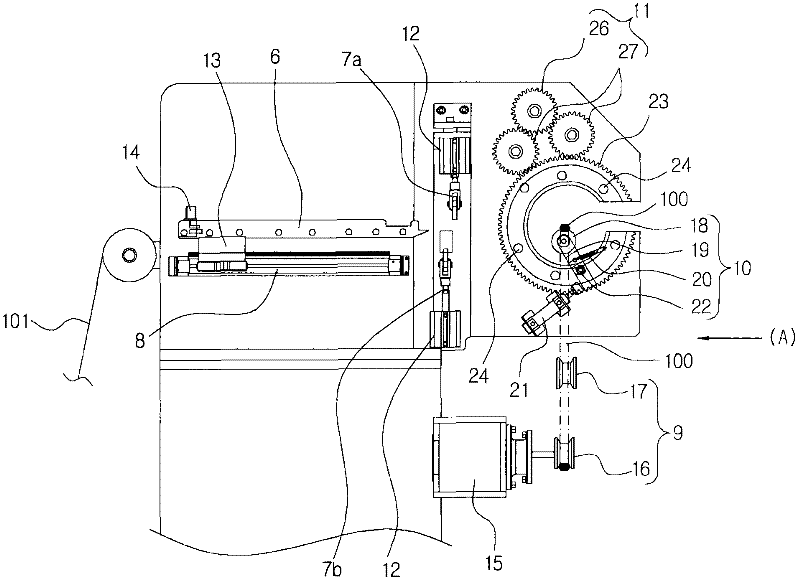

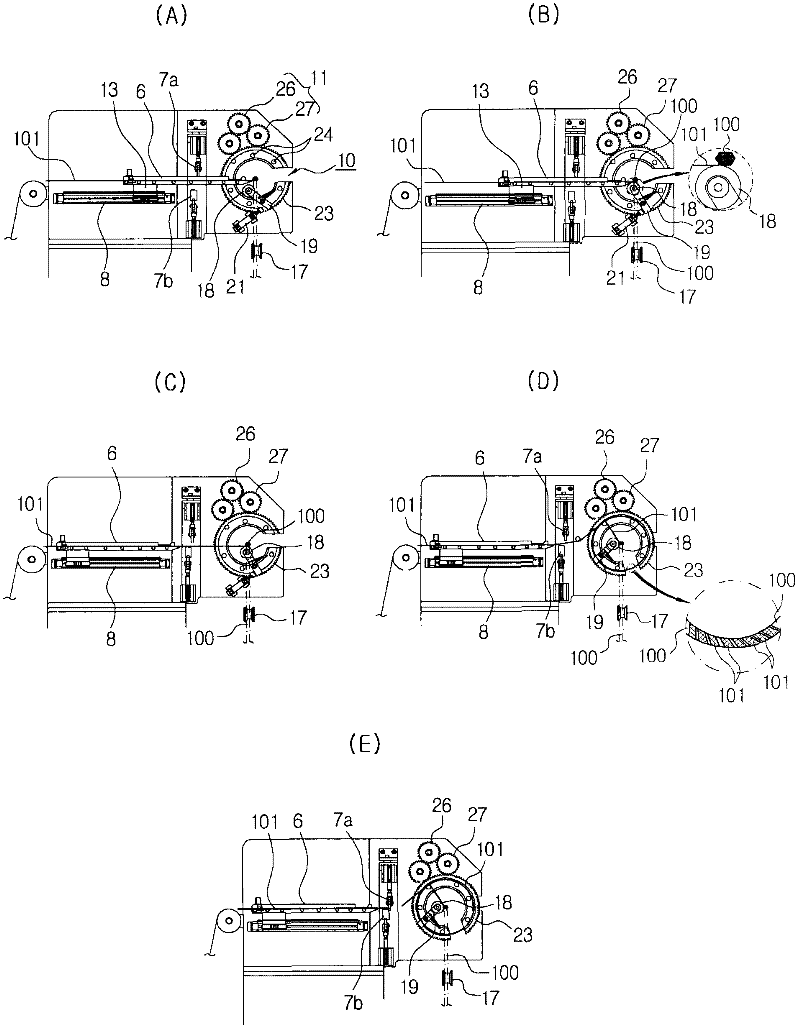

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 with figure 2 As shown, the present invention relates to a bead winding device, which includes a winder 1 for winding a winding material 101; a plurality of pulling rollers 3 connected to a motor 2 stretched and wound on the winder 1 the winding material 101; and the transfer device 6, which guides the winding material 101 stretched by the pulling roller 3 to the bead winding part 5 in an endless state. The above-mentioned bead winding unit 5 includes: a bead driving motor 15; a bead rotating unit 9 that rotates the bead through the bead driving roller 16 and the bead rotating roller 17 that transmit the power of the bead driving motor 15; The attachment unit 10 covers the wrapping material 101 over the entire circumference of the bead rotated by the bead rotation unit 9 ; and the driving rotation unit 11 drives the wrapping attachment uni...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap