Reservoir ink-filling machine

A technology of rolling and filling ink, which is applied in the direction of ink filling device, ink container, printing, etc., which can solve the problems of reducing writing length, heavy manual workload, dripping points, etc., to avoid ink leakage and dripping points, and reduce manual intervention , Improve the effect of ink filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

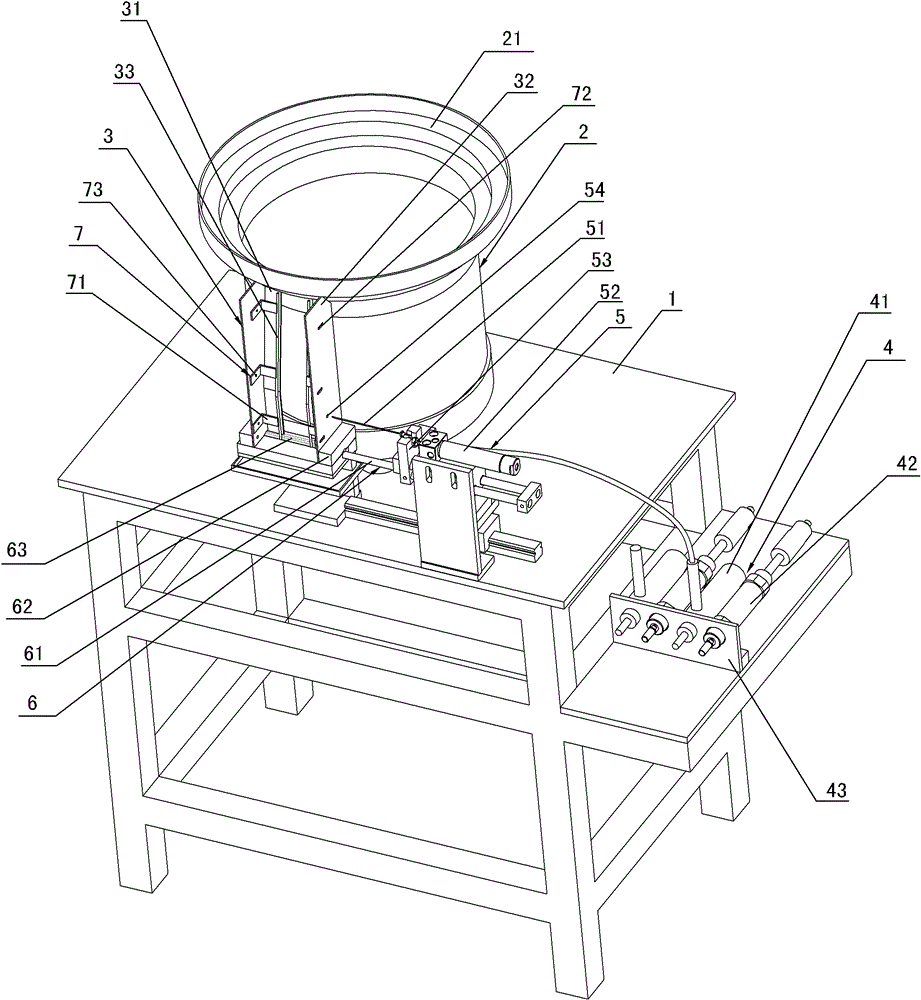

[0014] A kind of volume core ink filling machine that the present invention proposes, as figure 1 As shown, it includes a frame 1 and a feeding mechanism 2 arranged on the frame 1, a feeding arrangement rail 3, an ink filling mechanism 4, an ink filling mechanism 5, a pushing mechanism 6 and a controller (not shown in the figure) , the feeding mechanism 2 is mainly composed of a directional feeding vibrating plate 21 and a vibrating motor (not shown in the figure) connected to the directional feeding vibrating plate 21, and the ink filling mechanism 4 is mainly composed of a plug pump 41, an ink filling cylinder 42 and the first connection plate 43, the ink filling mechanism 5 is mainly composed of an ink injection needle 51, a needle tube cylinder 52, a second connecting plate 53, and a positioning through hole 54 arranged on the feeding arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com