Mounting structure for skylight rear drainer and skylight glass run of automobile

A technology for automobile sunroof and installation structure, which is applied in the directions of sealing device, vehicle parts, transportation and packaging, etc., can solve the problems of difficulty, long installation time, poor manufacturability, etc., achieves simple and convenient installation operation, saves installation time, Good installation craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

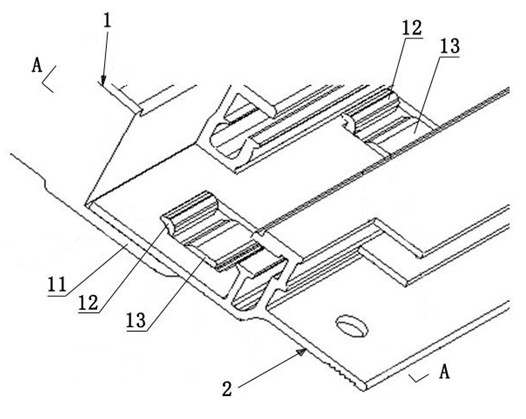

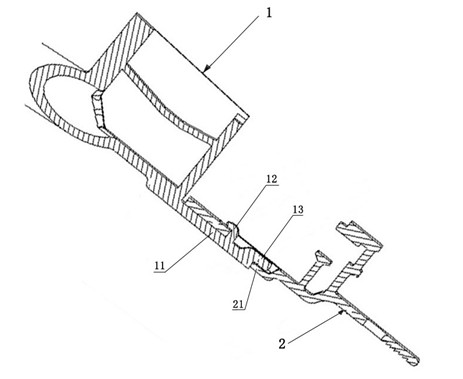

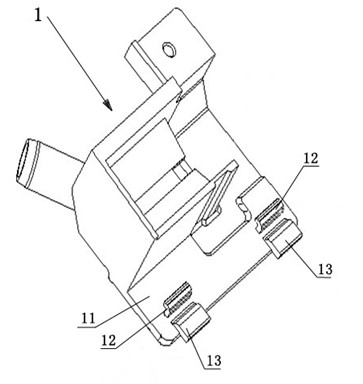

[0015] Such as Figure 1 to Figure 4 The installation structure of the car sunroof rear drain and the sunroof glass chute includes the sunroof rear drain 1 and the sunroof glass chute 2, the sunroof rear drain 1 is provided with a mounting plate 11, and the mounting plate 11 is provided with two clips Connector, each snap connector is made up of snap buckle 12 and the snap block 13 that is arranged on the edge of mounting plate 11, is provided with two snap holes 22 on the sunroof glass runner 2, and snap hole 22 is to connect with the clip. A square hole adapted to the adapter, one side edge of the square hole is provided with a receiving block 21 that cooperates with the clamping block 13, the clamping block 13 is supported on the receiving block 21, and the clamping buckle 12 is stuck on the receiving block 21. The edge of one side of the square hole is opposite to the edge of the other side of the square hole.

[0016] During installation, firstly insert the two clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com