Passenger conveying equipment

A technology for passenger conveying equipment and alarms, applied in transportation and packaging, escalators, etc., can solve problems such as motor burnout and unfavorable passenger safety, and achieve the effect of preventing burnout, maintaining service quality, and ensuring smooth movement of people.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described below with reference to the drawings.

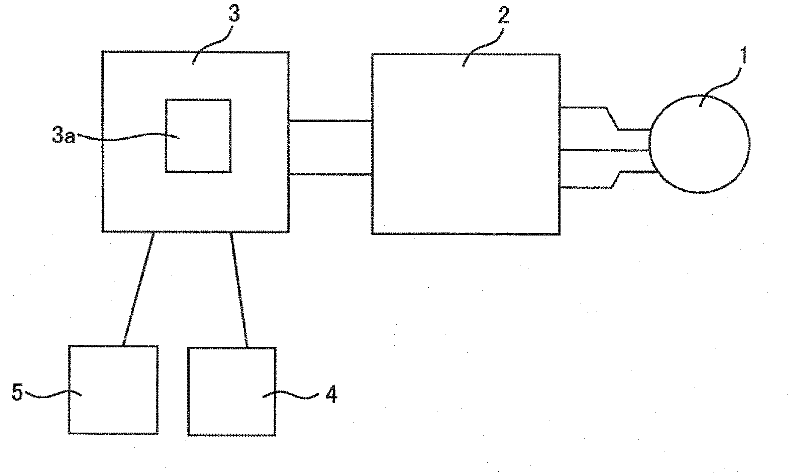

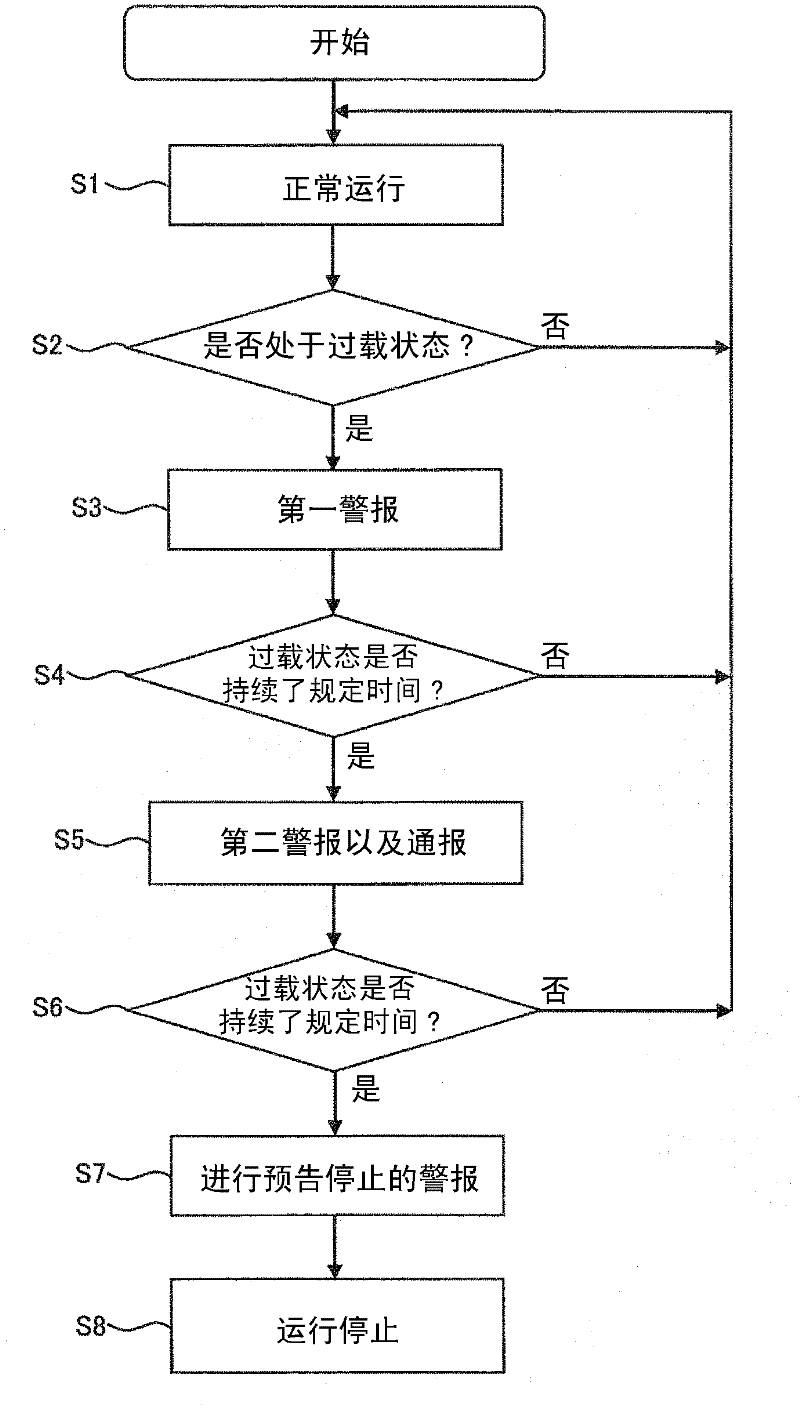

[0021] Such as figure 1 As shown, the passenger conveying equipment of this embodiment has: a motor 1 for driving an unillustrated pedal connected in a loop to convey passengers, etc.; an inverter 2 connected to the motor 1; a control section for performing operation control 3; the overload detection part 3a, which detects the overload state, and outputs an output signal representing the overload state; the alarm part 4, which is arranged on the side of the main body of the passenger conveying device, and is used to issue an alarm; and the notification part 5, which is arranged on the The duty room on duty is used for issuing announcements. Among them, the overload detection part 3a is built in the control part 3, detects the overload state according to the inverter load information of the inverter 2, and outputs an output signal indicating the overload state when the overlo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com