Method and device for aseptic filling

A technology of aseptic filling and conveying device, which is applied to the safety device of filling device, packaging, bottling machine, etc., can solve the problems of low efficiency and high cost, and achieve the effect of economical operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

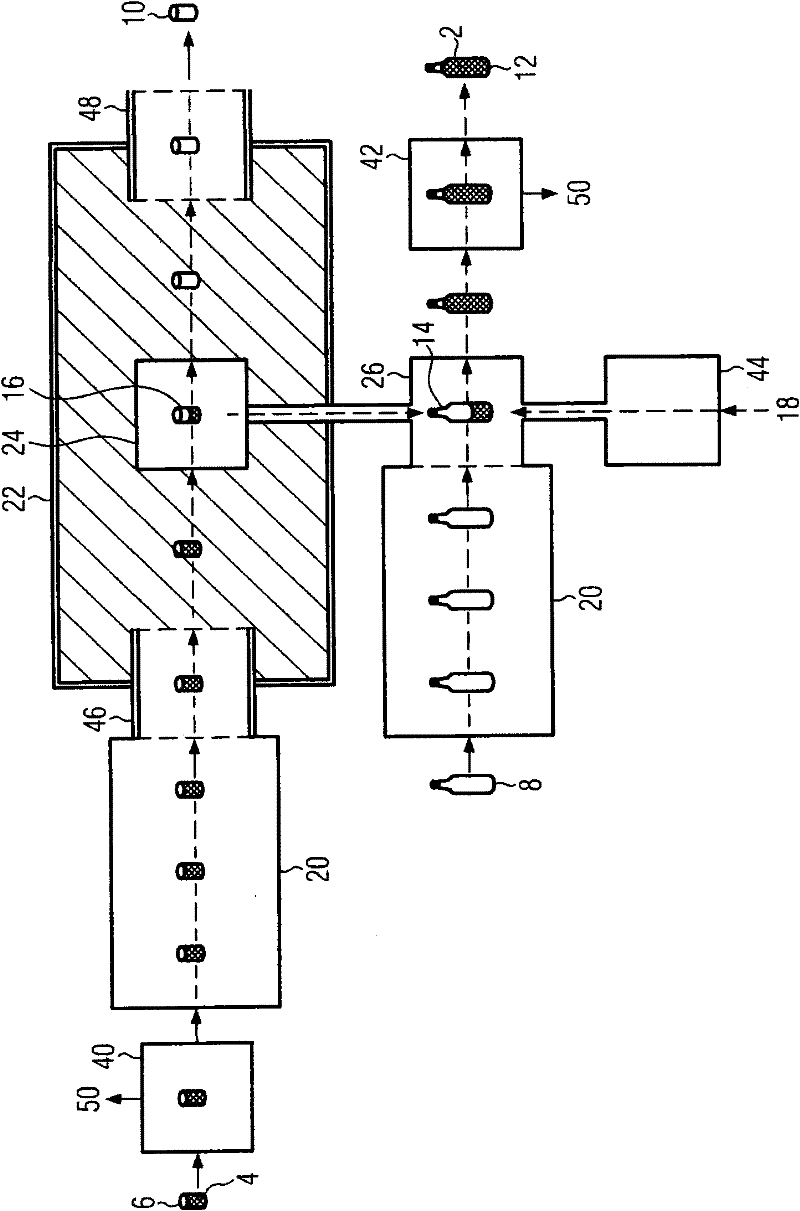

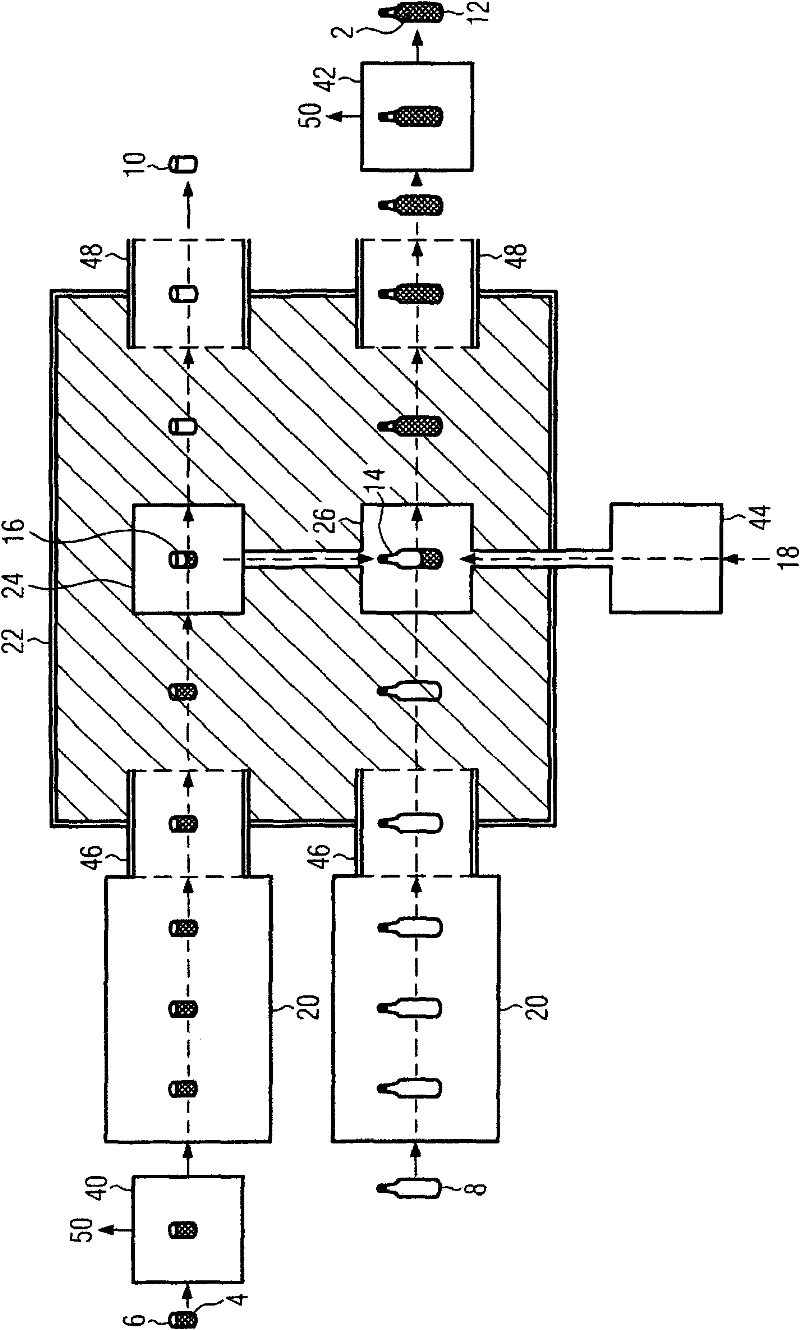

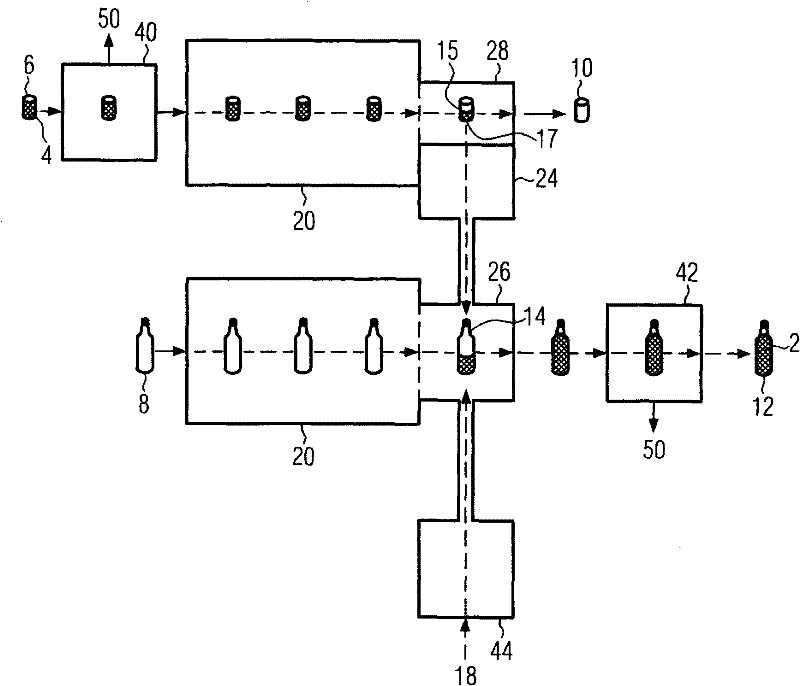

[0059] figure 1 The device is shown with a test unit 40 for testing the leak-tightness of the first container 6 and a disinfection unit 20 for sterilizing the outer surface of the first container 6 . Furthermore, the device comprises a clean room 22 with a conveying device 46 for introducing full first containers 6 and a second conveying device 48 for removing empty first containers 10 . The clean room 22 comprises an opening unit 24 for opening the sterilized first container 16 and removing solid particles 4 from the container 16 . In addition, the device comprises a filling unit 26 and a second sterilization unit 20 for sterilizing the empty second container 8 to be filled with the food product 2 . The filling unit 26 is coupled with the opening unit 24 and the pasteurization unit 44 via ducts through which solid particles 4 or liquid food 18 are fed into the filling unit 26 . In addition, the device includes a metal detector 42 for detecting metal in the second container ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com