Angle steel non-slip ramp

A technology of anti-slip and angle steel, which is applied in the direction of roads, roads, climate change adaptation, etc., can solve the problems of passenger discomfort, wear and tear, and non-slip slopes do not have drainage functions, etc., to achieve convenient use, prolong service life, and avoid slopes slippery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

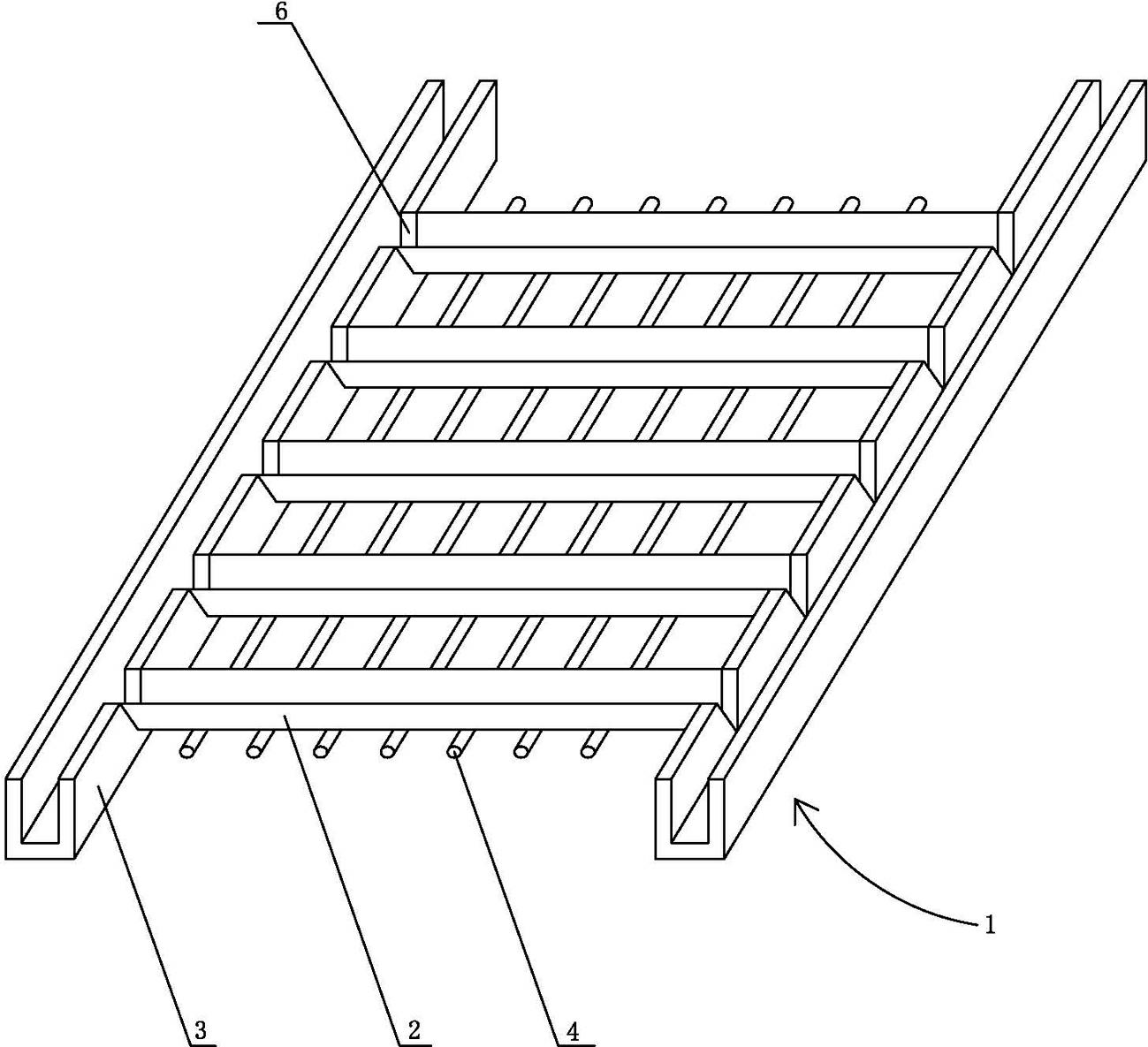

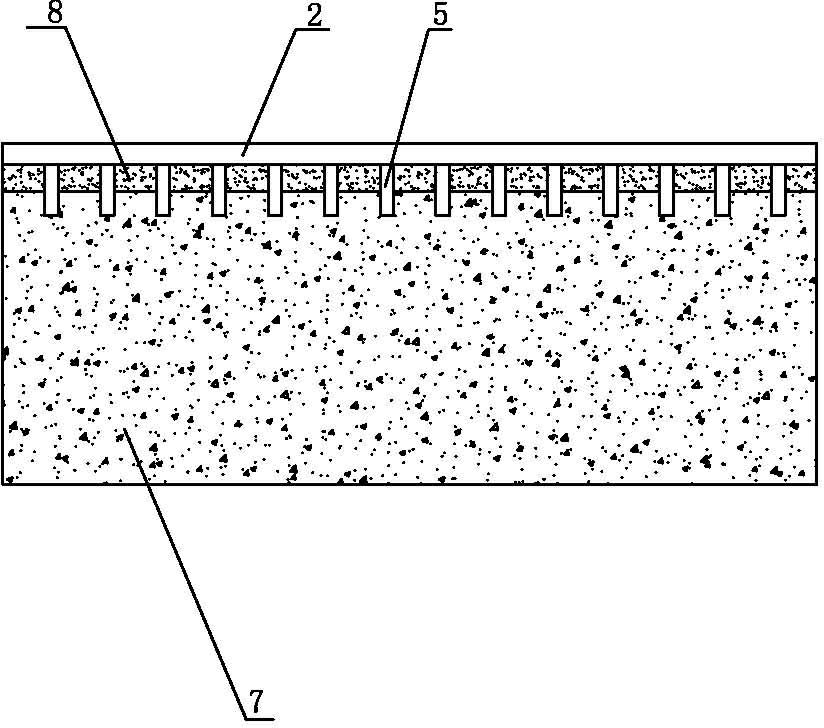

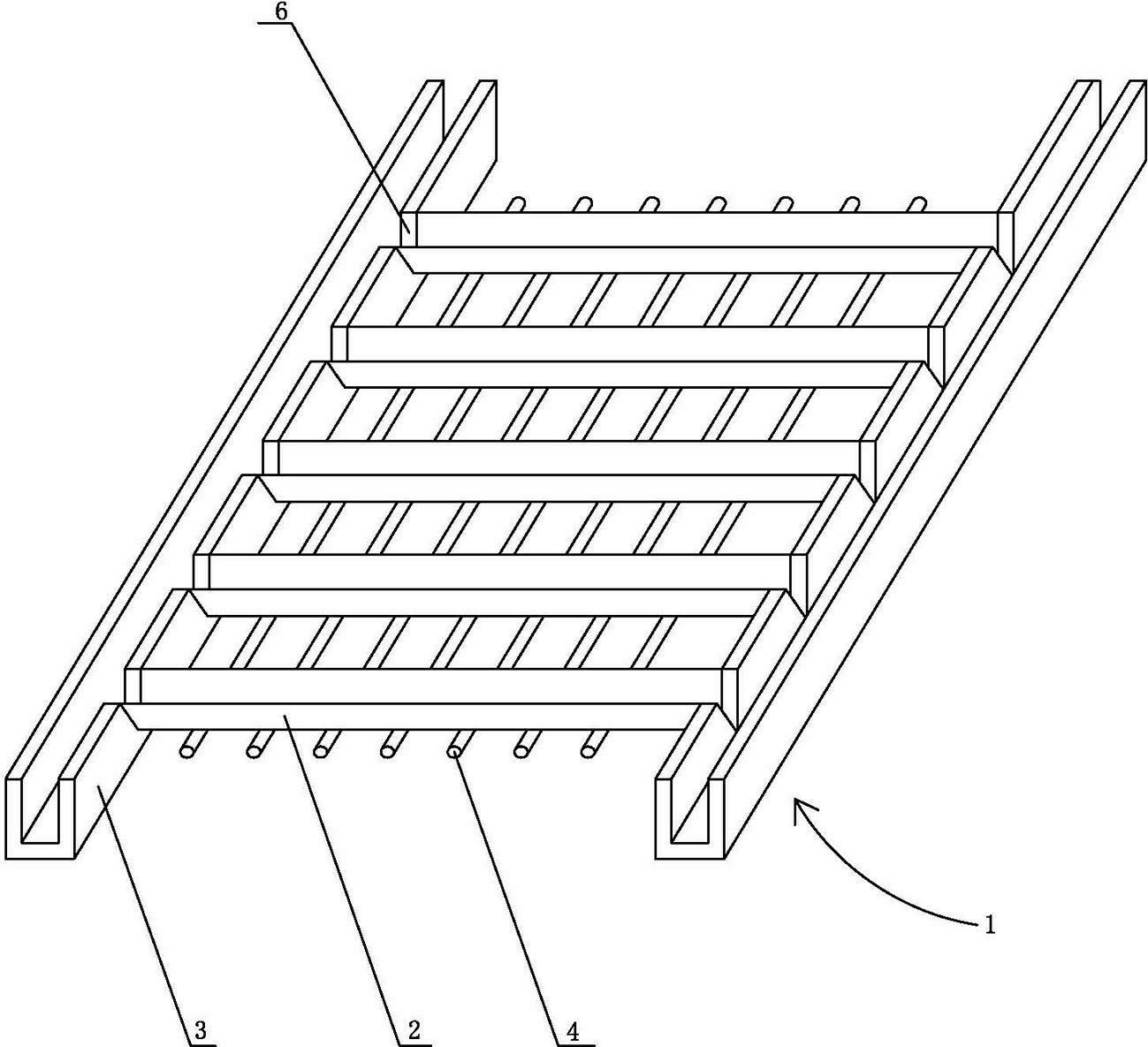

[0012] Embodiment 1: An angle steel anti-slip ramp, including an anti-slip frame 1 and a concrete layer 7, the anti-slip frame 1 is fixed on the concrete layer 7, and the anti-slip frame 1 is welded with No. 4 channel steel 3 and L35×3 angle steel 2 As a result, two channel steels 3 are arranged on both sides of the anti-skid frame 1 as vertical keels; the angle steels 2 are in the shape of a "V", and several angle steels 2 are welded to the channel steels 3 on both sides at intervals of 150 mm to make It is a horizontal keel; the connection between the channel steel 3 and the angle steel 2 is provided with a channel steel opening 6, so that the accumulated water in the angle steel 2 can flow from the channel steel opening 6 to the channel steel 3, and the channel steel 3 is used as a drainage channel; in the angle steel Round steel 4 is also welded below 2, and round steel 4 is welded and fixed with several angle steels 2 at the same time to strengthen the firmness of angle st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com