Series connection process device for freezing pipes of pitshaft of overlength inclined shaft

A technology for freezing pipes and inclined shafts, which is applied in shaft equipment, sinking, mining equipment, etc. It can solve the problems of increased freezing costs and increased power consumption, and achieves the reduction of total circulation of brine, reduction of power consumption, and simple installation structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

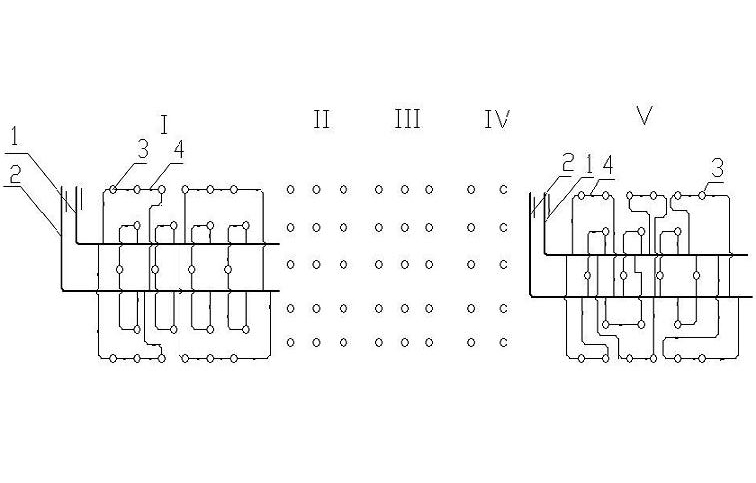

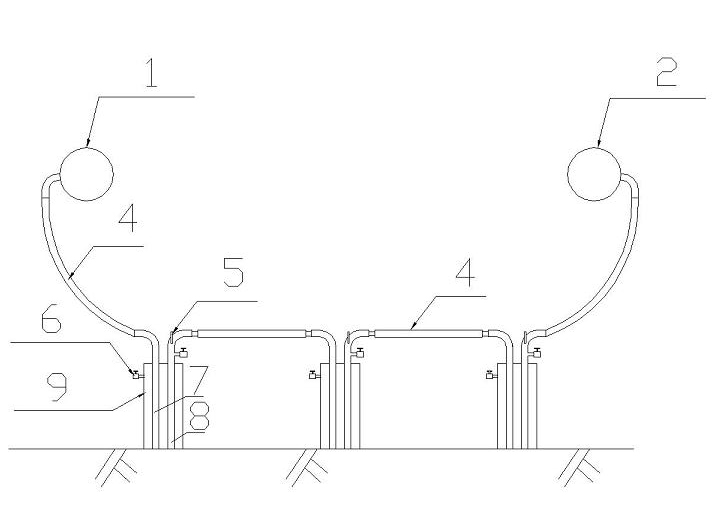

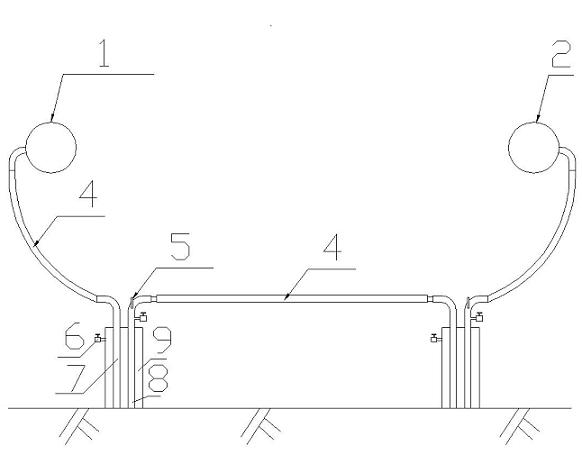

[0015] Such as Figure 1-3 As shown, a super-long inclined shaft shaft freezing pipe series process device is provided with 5 rows vertically and horizontally with a plurality of freezing holes 3 on the ground of the ultra-long inclined shaft shaft, and a freezing pipe is installed in each freezing hole 3 9. The freezing pipe 9 is provided with a liquid inlet pipe 7 and a liquid outlet pipe 8; along the horizontal direction of the freezing hole, it is divided into sections I, II, III, IV, and V, and each section is provided with a brine inlet pipe 1 and Brine liquid return main pipe 2; Sections I, II, and III adopt three freezing pipes in series, in which the liquid inlet pipe of the first freezing pipe is connected with the brine liquid inlet main pipe, and its outlet pipe is connected with the liquid inlet pipe of the second freezing pipe connection, the liquid outlet pipe of the second freezing pipe is connected with the liquid inlet pipe of the third freezing pipe, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com