Process for reducing energy consumption of absorption and stabilization system in oil refining process

An absorption stabilization system and oil refining process technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of inability to benefit absorption, reabsorption, desorption and stabilization at the same time, and achieve reduction of the total amount of internal circulation, Effects of better absorption, enhanced absorption and reabsorption process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

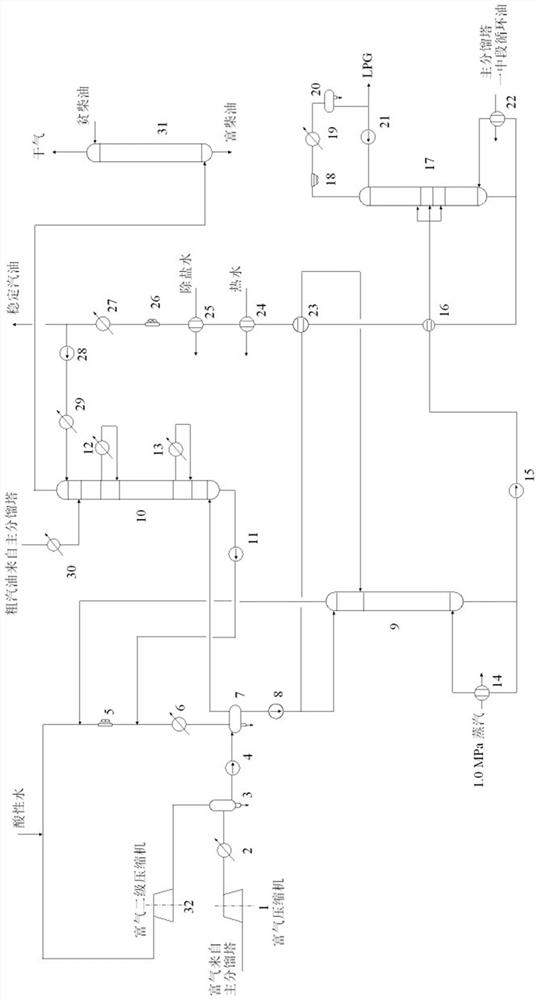

Image

Examples

Embodiment

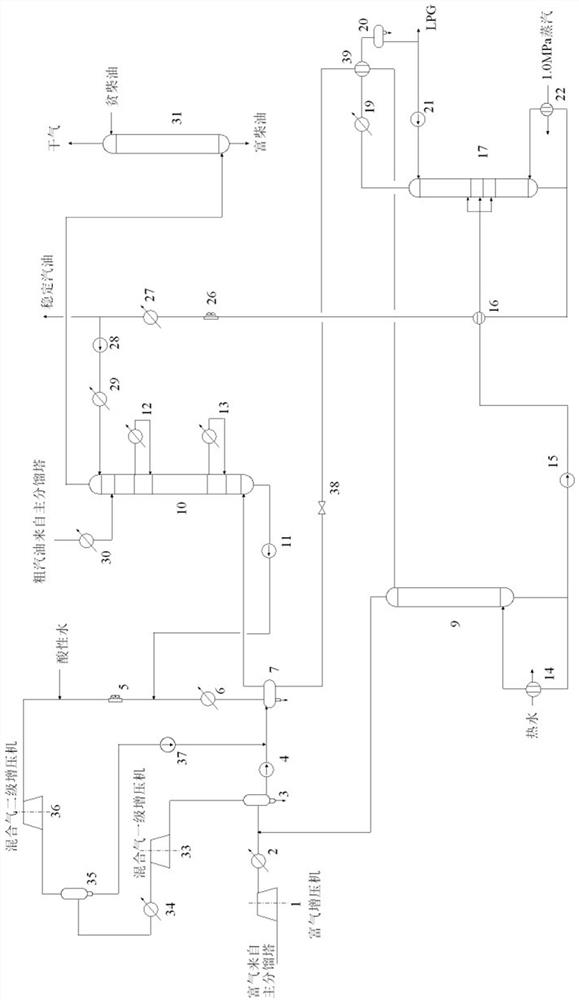

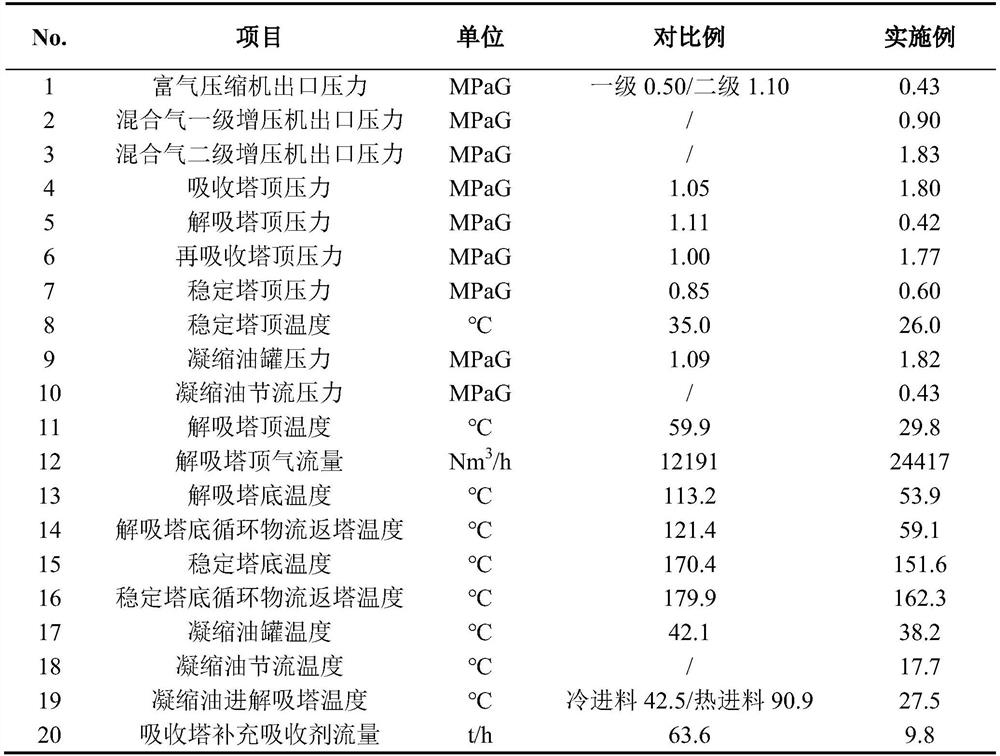

[0095] This embodiment is a differentiated absorption stabilization system in the refining process and a new pressure swing operation new process, which is an improvement on the original process flow, and its structural diagram is as follows figure 2 shown. (other undescribed processes are all the same as the comparative example, so I won't repeat them here):

[0096] The absorption stabilization system of the refinery process of the embodiment not only includes: rich gas compressor 1, compressed rich gas liquid separation tank 3, condensed oil tank 7, stable tower top circulating water cooler 19, stable tower top reflux tank 20, absorption Tower 10, desorption tower 9, stabilizing tower 17 and reabsorption tower 31; Also include: mixed gas primary booster 33, mixed gas circulating water cooler 34, compressor interstage liquid separation tank 35, mixed gas secondary booster Compressor 36, interstage liquid separation oil pump 37, condensed oil throttle valve 38 and low-tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com