Method and system for solving problem of exhaust gas recirculation (EGR) drive hysteresis

A hysteresis and engine technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve problems such as inconsistent strokes, affecting the recirculation effect of the exhaust gas recirculation system, EGR drive hysteresis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The core of the present invention is to provide a method and system for solving EGR driving hysteresis, which can avoid the hysteresis phenomenon that occurs when the duty ratio changes from large to small or from small to large.

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. For ease of understanding and brevity of description, the method and system for solving the EGR driving hysteresis will be described below, and the beneficial effects will not be discussed repeatedly.

[0031] The system to solve the EGR driving hysteresis mainly includes: storage unit, acquisition unit, analysis unit and execution unit. The main operation process of the system can be understood in conjunction with the following content.

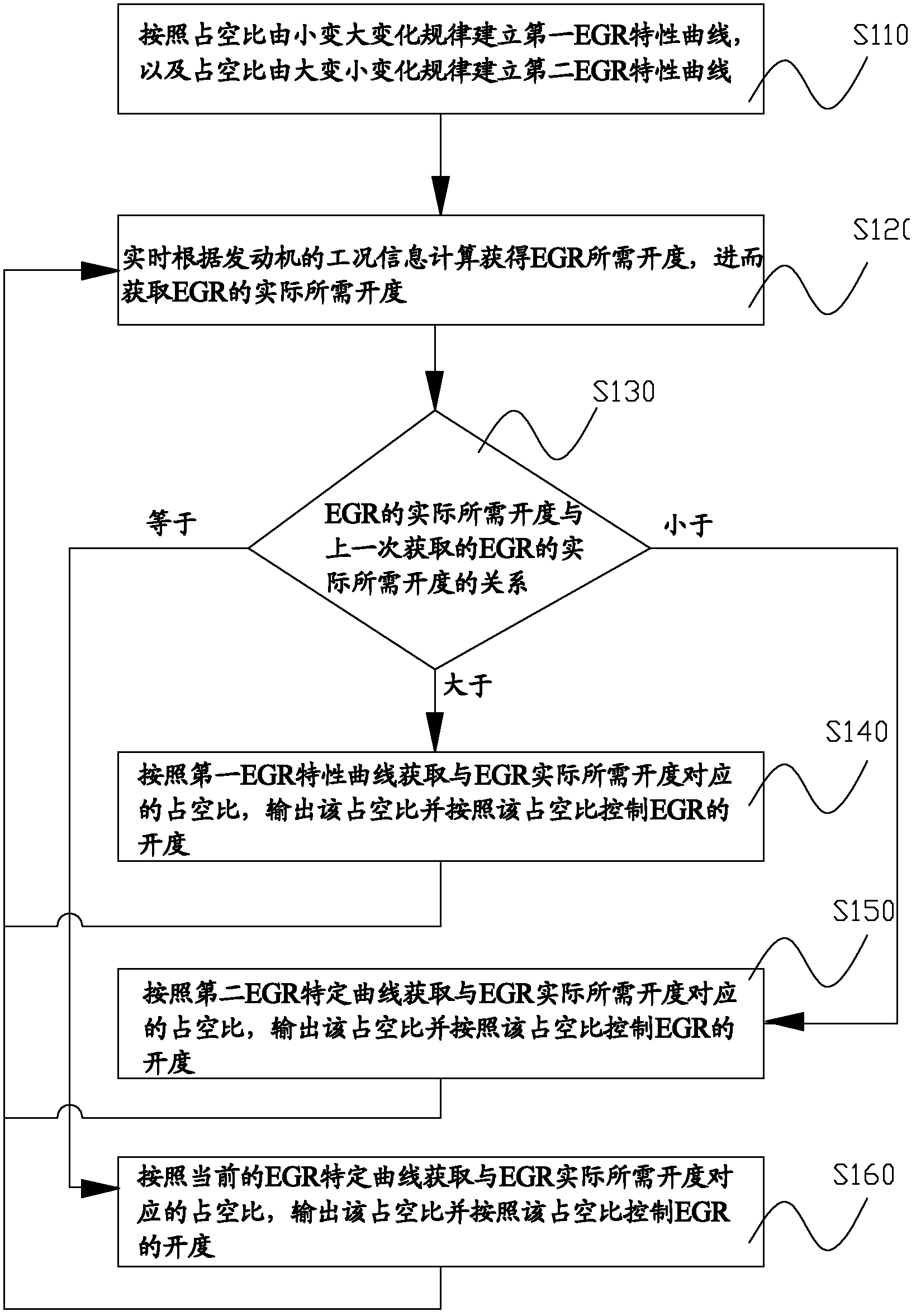

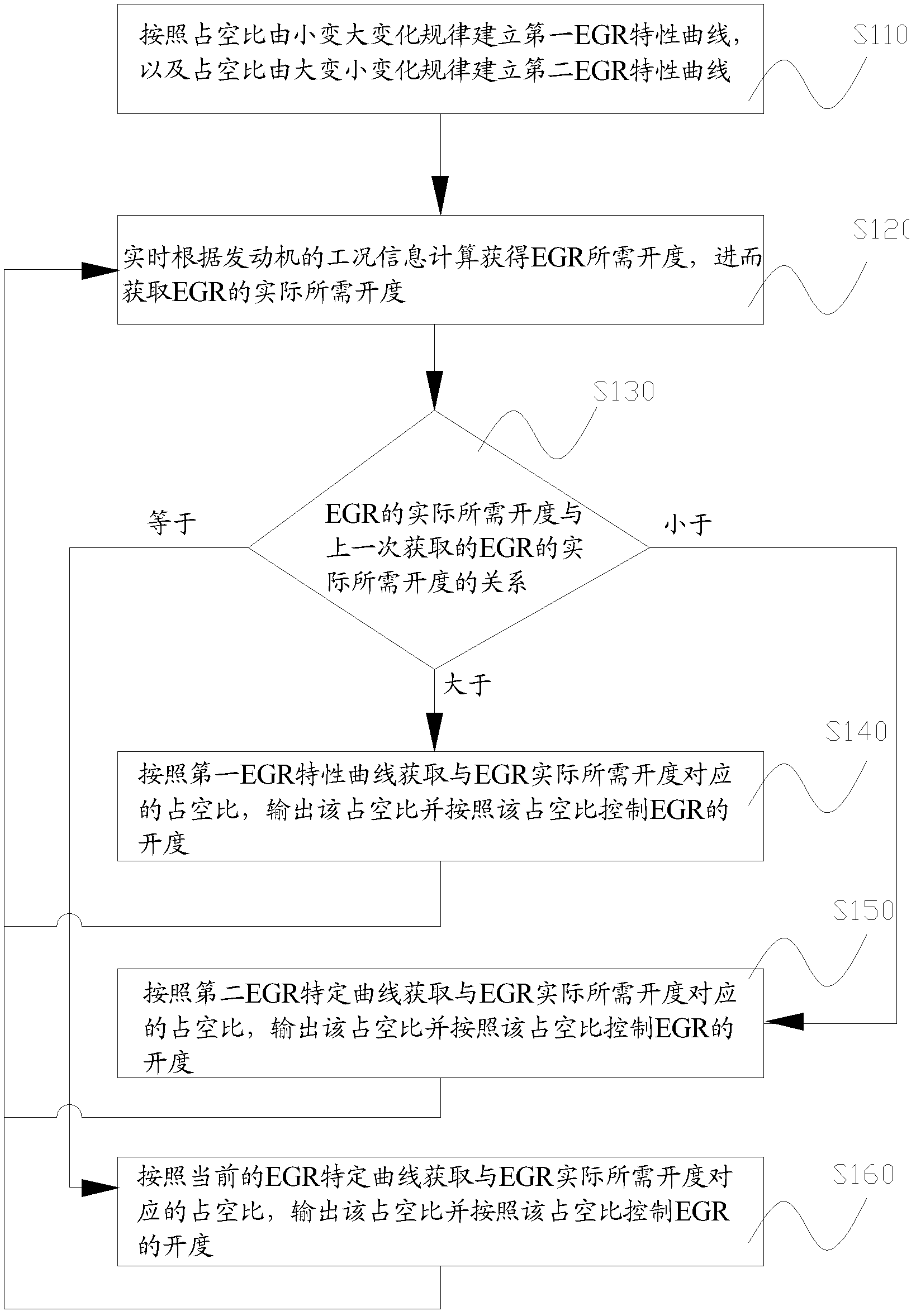

[0032] Please refer to figure 1 , figure 1 It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com