Microcrystalline low-temperature lens and camera using same

A low-temperature, microcrystalline technology, applied in the field of low-temperature lenses, can solve problems such as inability to completely eliminate, and achieve the effect of simple and practical system design, avoidance of changes, and simple working principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

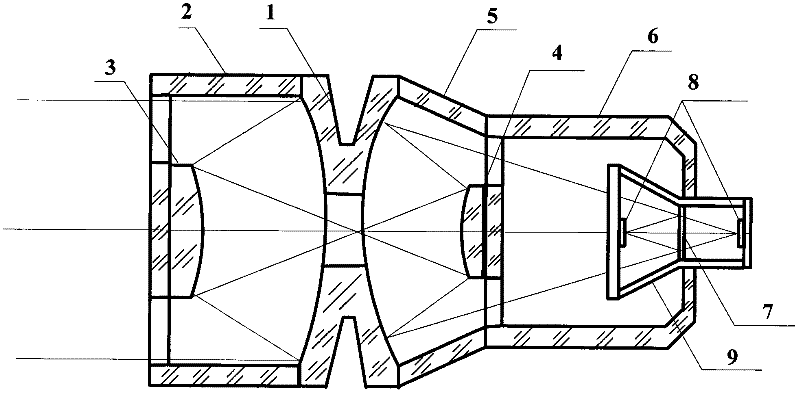

[0034] Working band B1 of full microcrystalline lens: 5.0~7.6μm, B2: 8.2~12.0μm, entrance pupil diameter: 300mm, F number 1.5, effective field of view is 4°; detector B1 spectrum and B2 spectrum pixel The size is 30μm area array CCD. The primary mirror / fourth mirror (1) is a concave hyperboloid mirror, the secondary mirror (3) is a convex hyperboloid mirror, and the third mirror (4) is a convex spherical mirror.

[0035] The working environment temperature for processing, assembly and testing is 293K, and the working environment temperature is 120K.

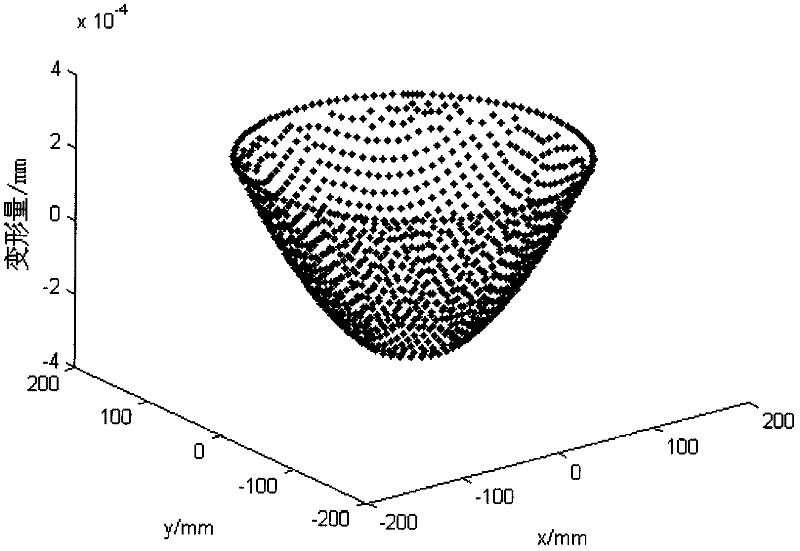

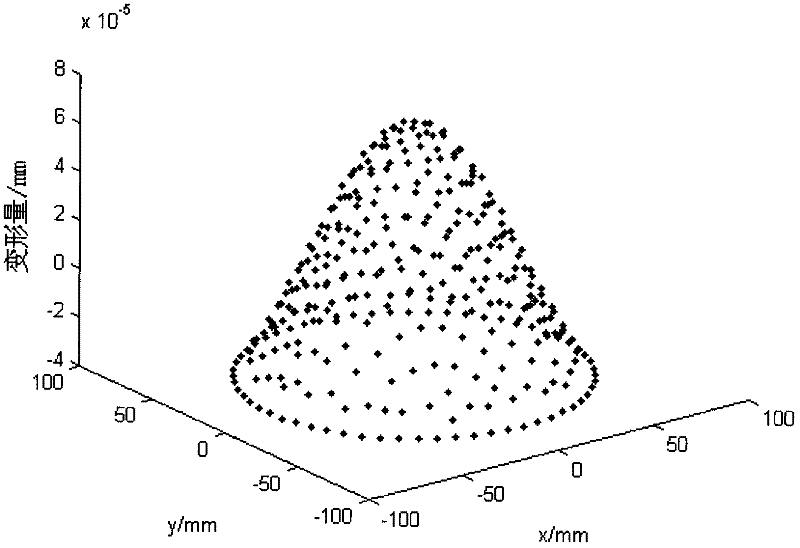

[0036] In this embodiment, when the temperature is lowered from 293K to 120K, the deformation of each mirror surface of the full microcrystalline cryogenic lens is as follows: Figure 2a-2d As shown, the deformation of each mirror is symmetrical.

[0037] In this embodiment, under the working conditions of 293K and 120K, the energy concentration of the pixel in the B1 and B2 bands of the full microcrystalline cryogenic lens is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com