Installation structure of vertical self-priming pump on chemical tank

A technology of installation structure and self-priming pump, which is applied in the direction of non-variable pumps, components of pumping devices for elastic fluids, pumps, etc., can solve the problem of non-explosion-proof solutions, long-axis submerged pumps with short service life, and easy Problems such as metal friction occur, and the installation method is simple and reliable, cost saving, and the process is simple and easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

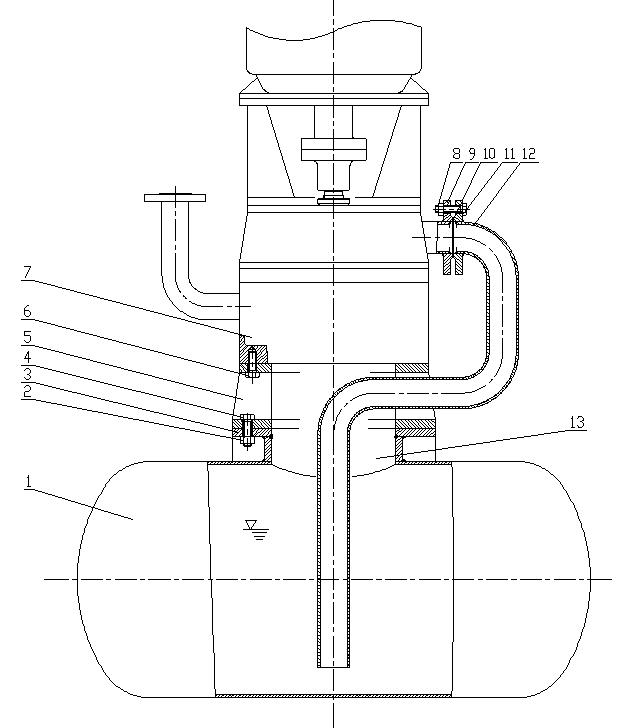

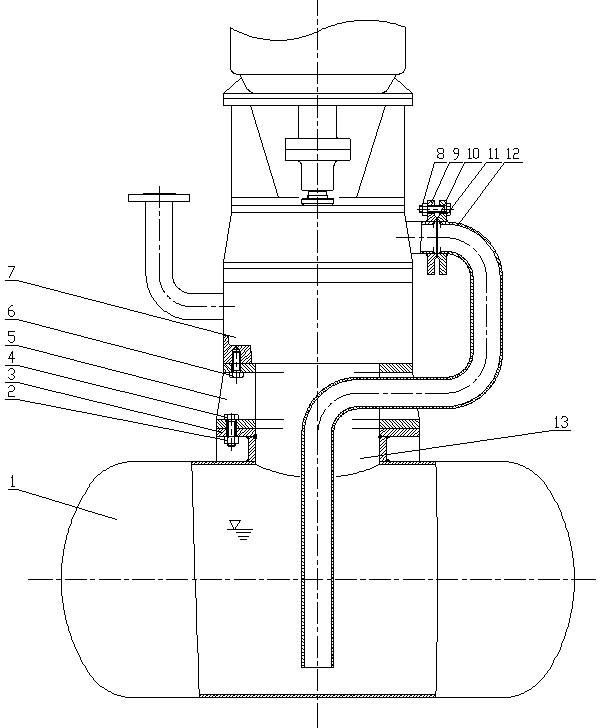

[0010] control figure 1 , its installation structure includes tank body 1, tank body flange 3, base 5, vertical self-priming pump 7, vertical self-priming pump inlet flange 9, inlet special-shaped pipe 12, wherein the base 5 is installed on the vertical On the vertical self-priming pump 7, the inlet special-shaped pipe 12 passes through the base 5 and is fixed on the inlet flange 9 of the vertical self-priming pump through C bolts 11 and B nuts 8, and the inlet special-shaped pipe 12 and the vertical self-priming pump inlet flange 9 is sealed with imported rubber gasket 10, lift the vertical self-priming pump 7 and install the vertical self-priming pump on the tank flange 3 through the base 5, the base 5 and the tank flange 3 use A bolts 4. A nut 2 is connected and fixed. There is a tank flange opening 13 on the tank flange 3. One end of the inlet special-shaped pipe 12 extends into the liquid in the tank 1. In this way, the vertical self-priming pump 7 is installed in the tan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com