Patents

Literature

48results about How to "Simple and reliable installation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

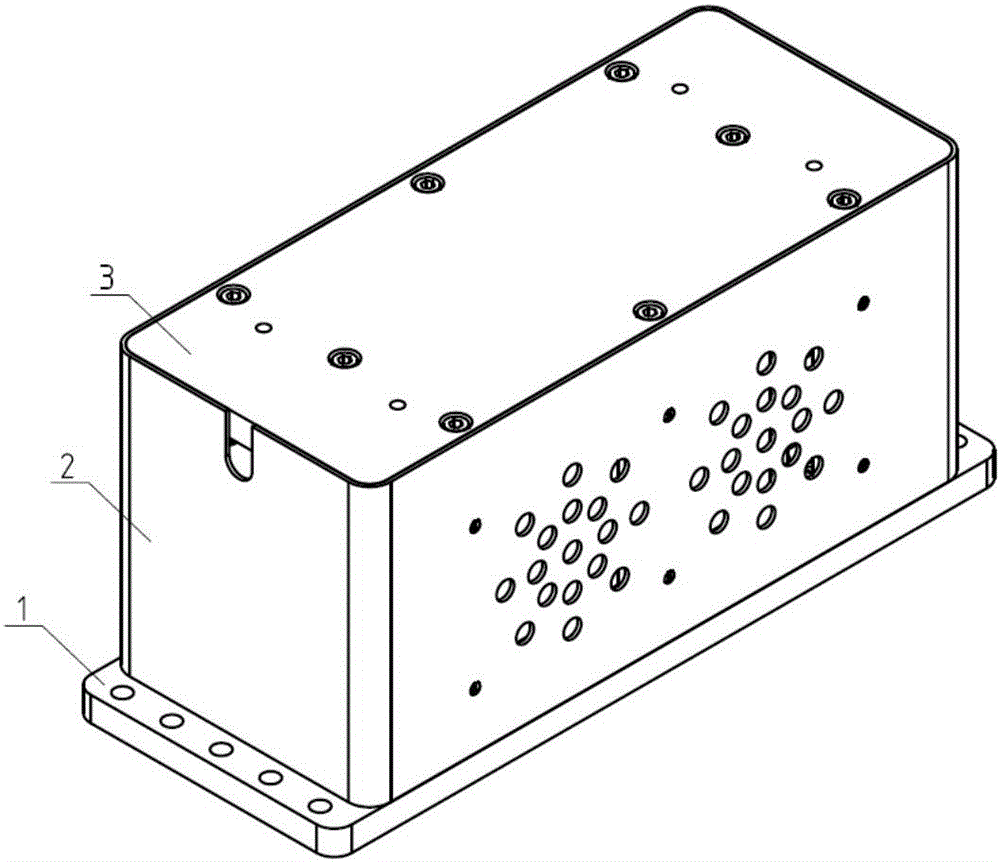

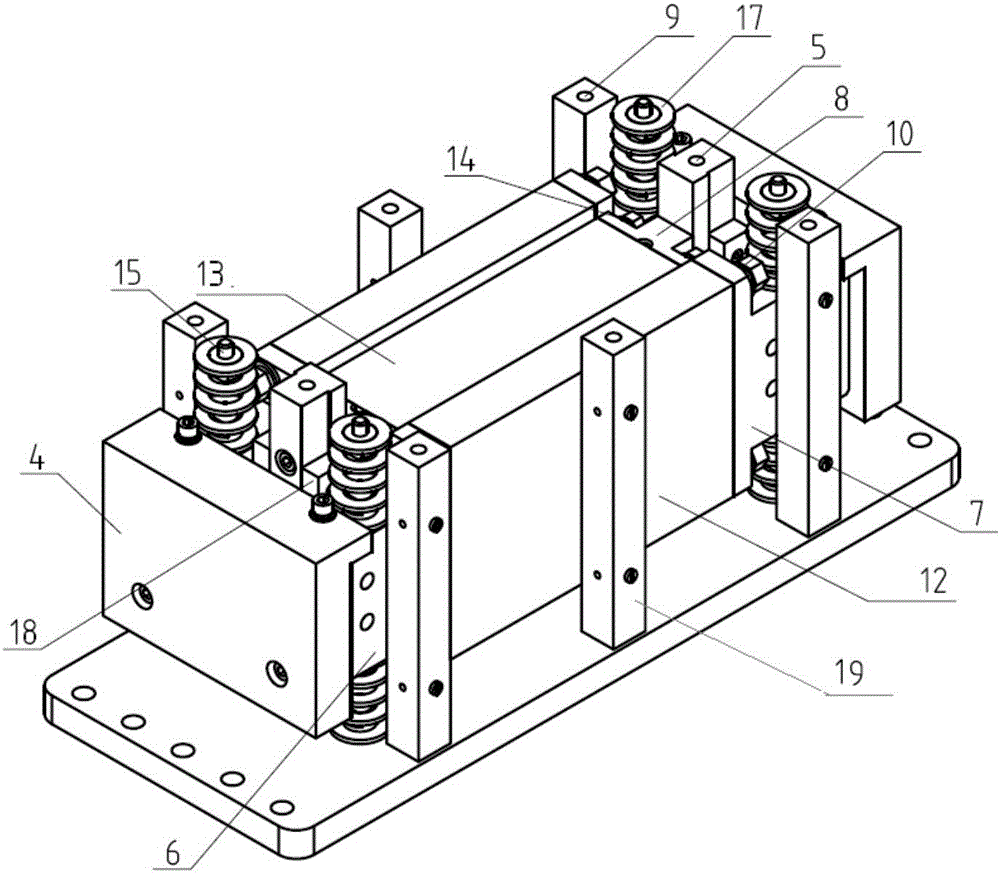

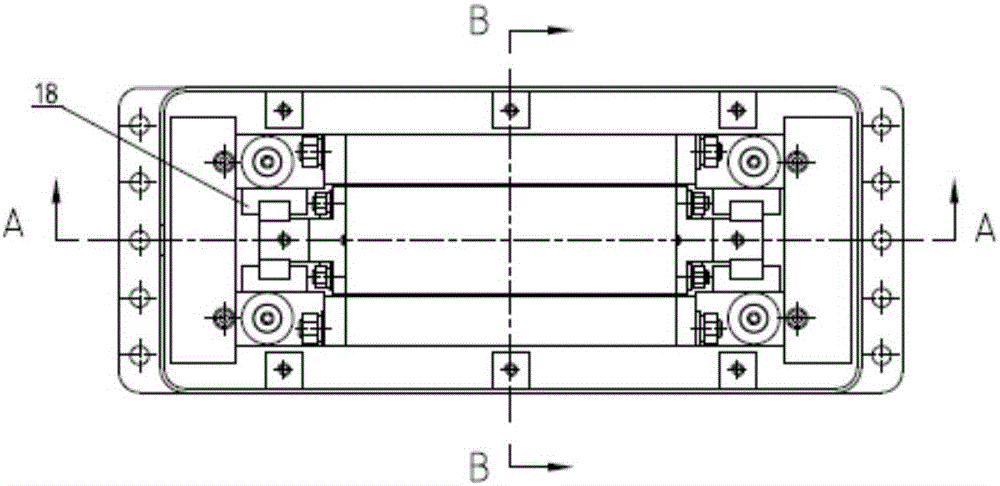

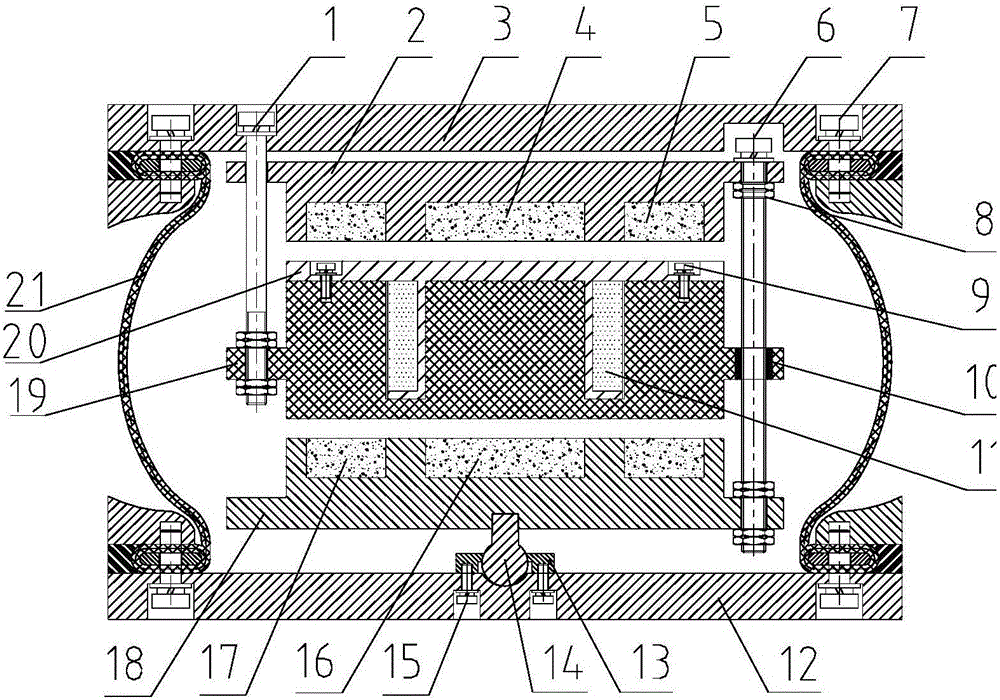

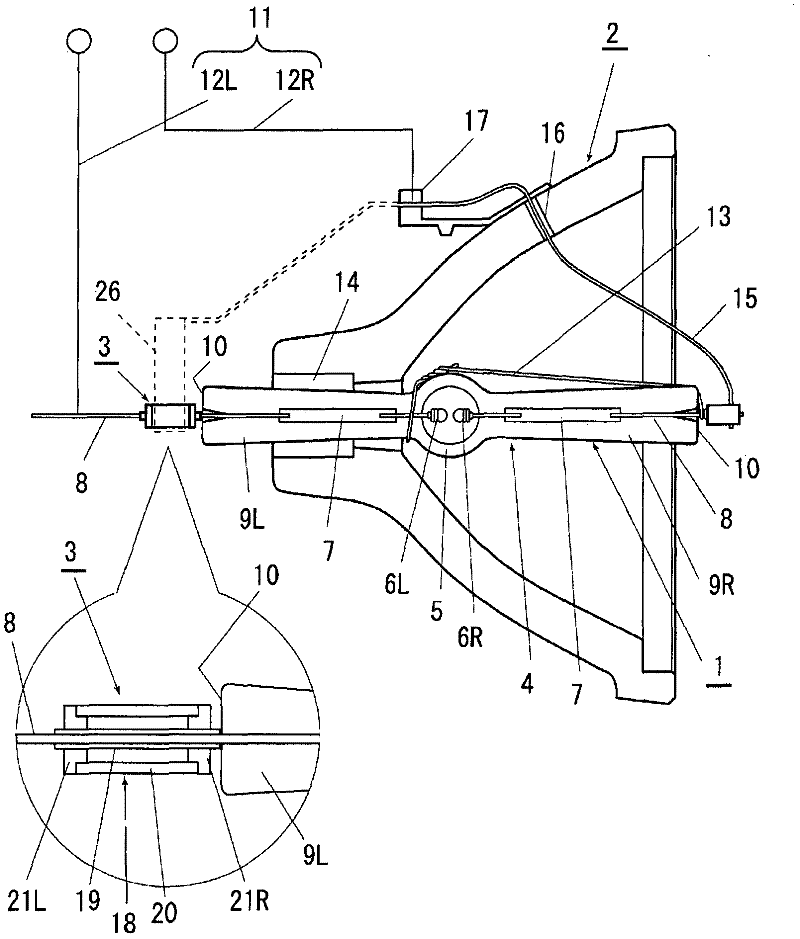

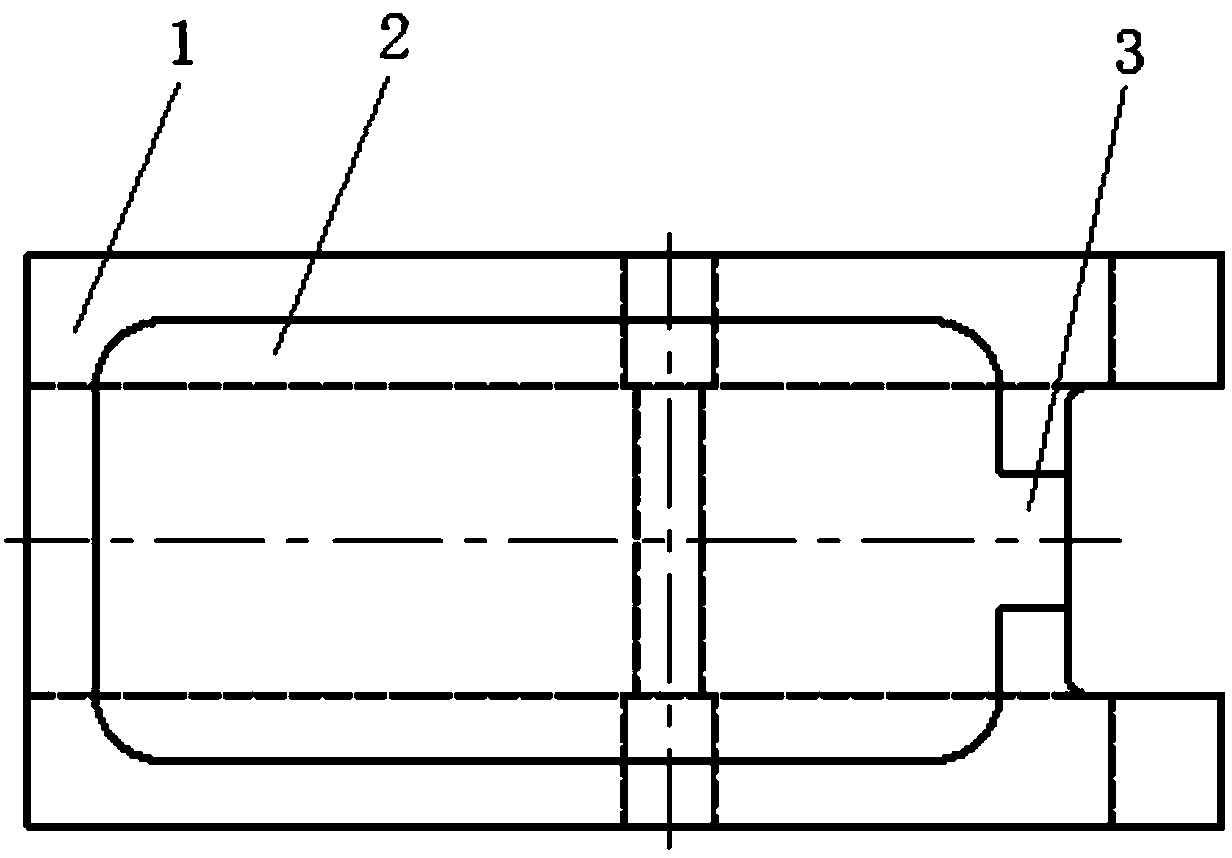

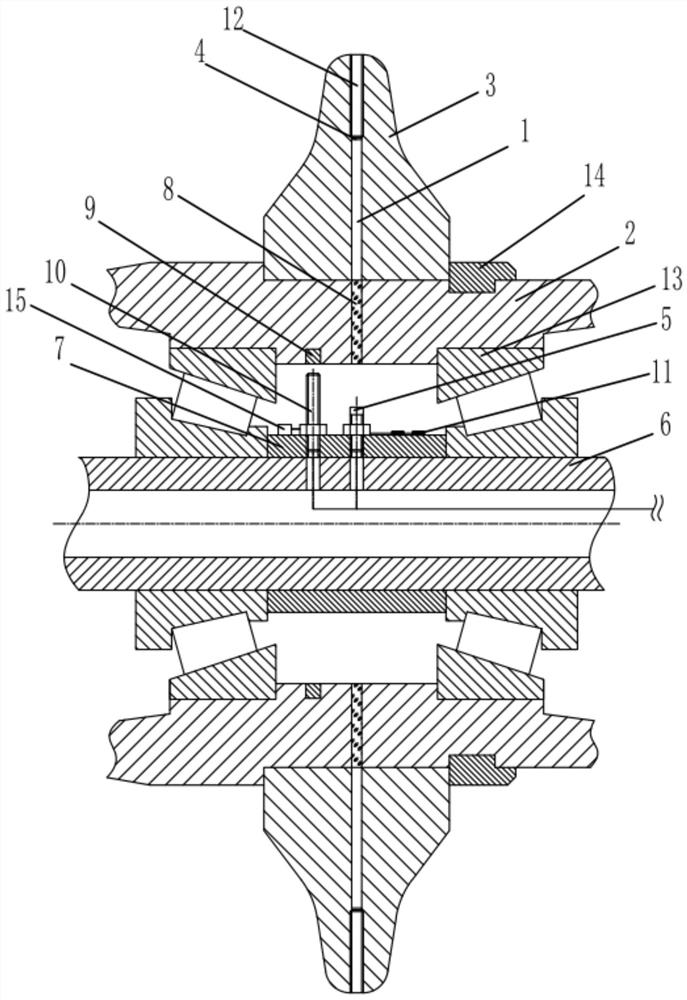

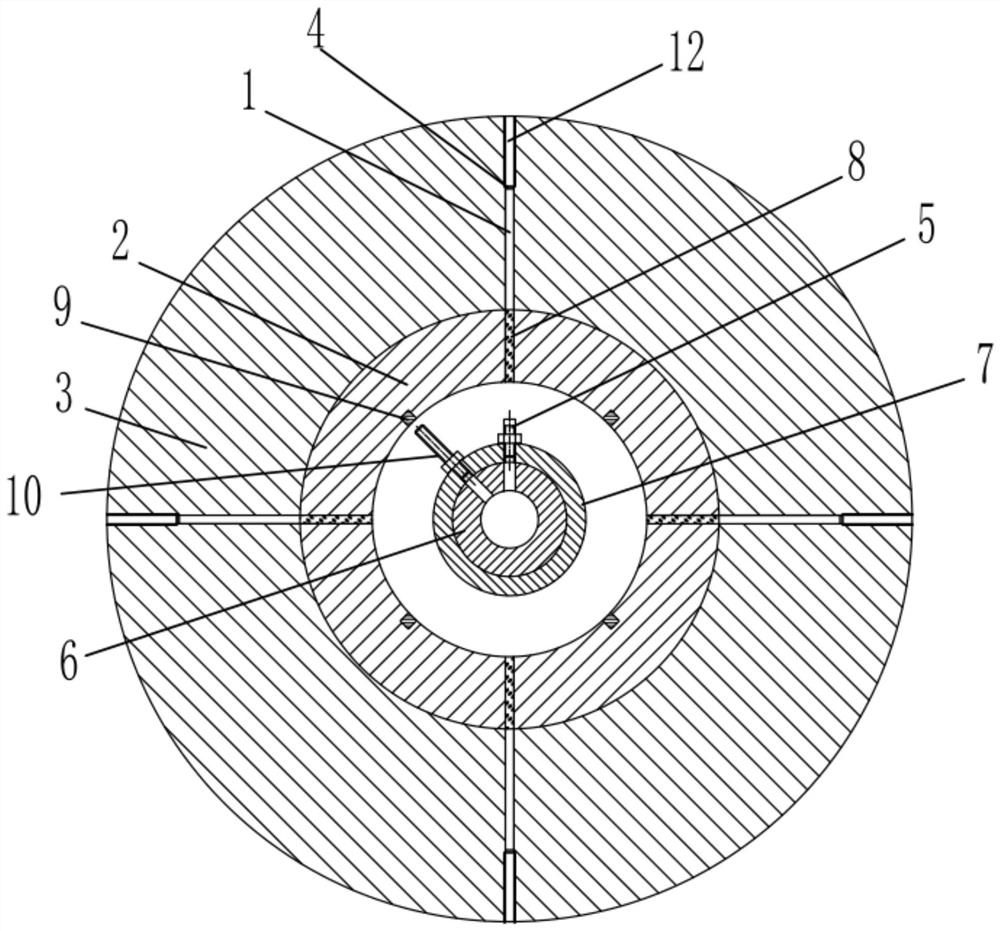

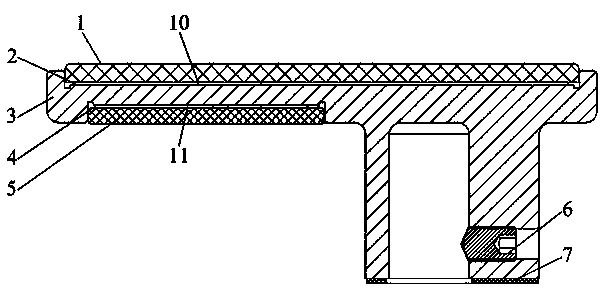

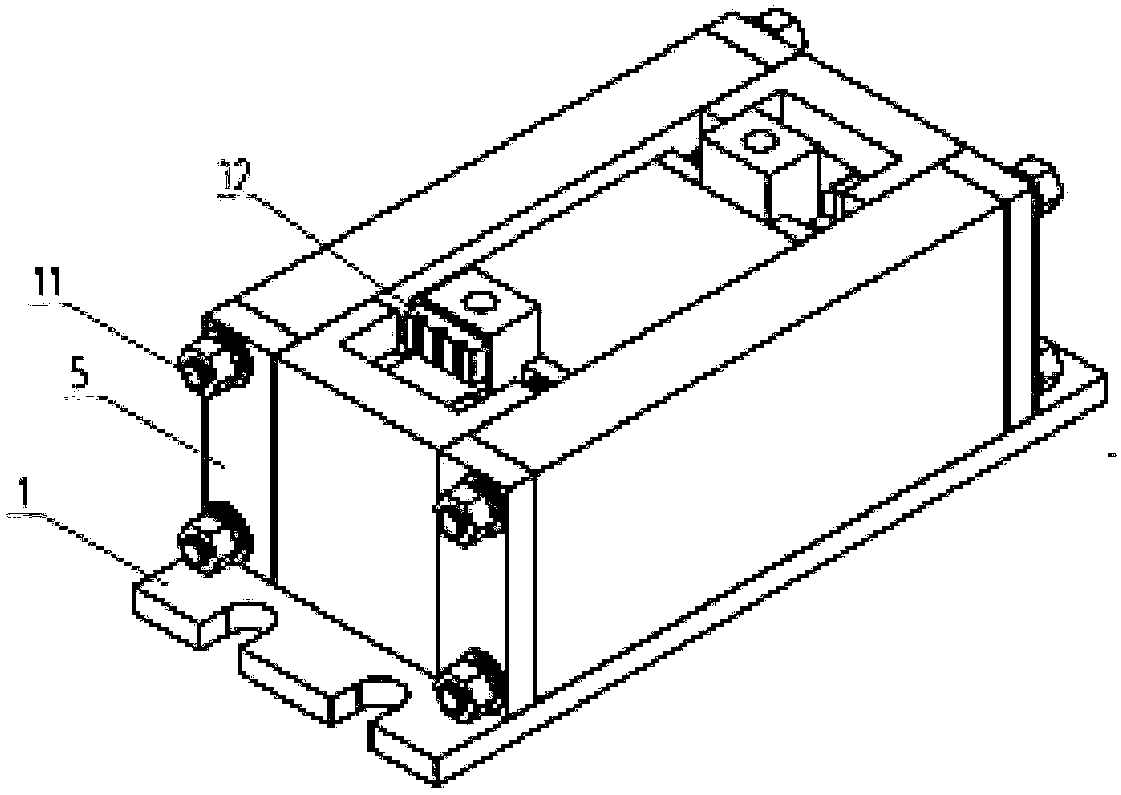

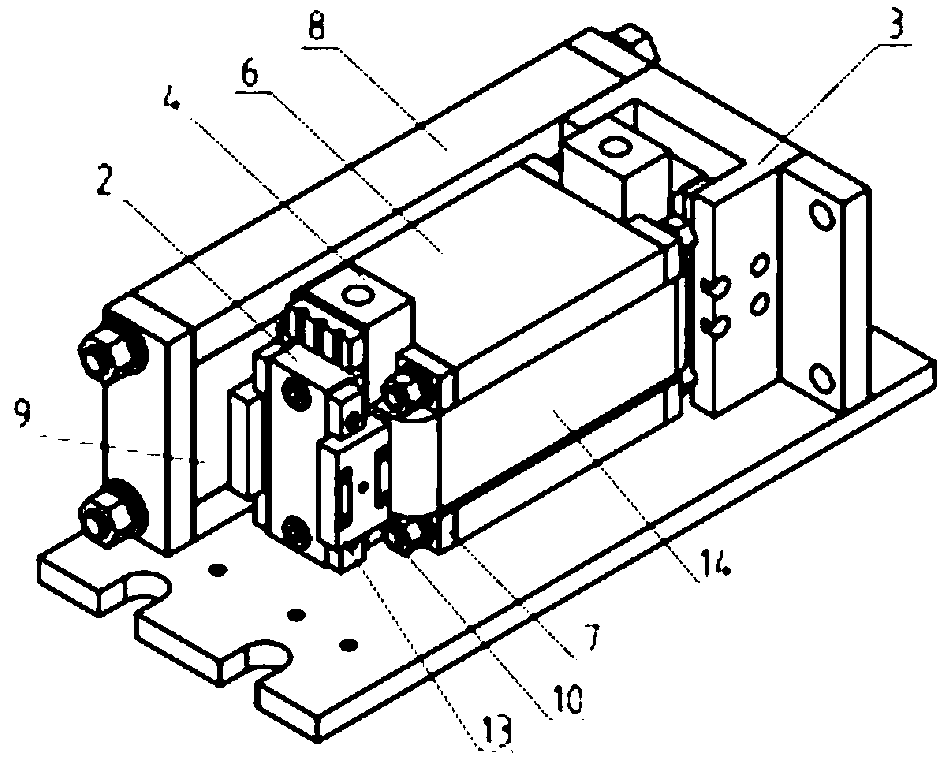

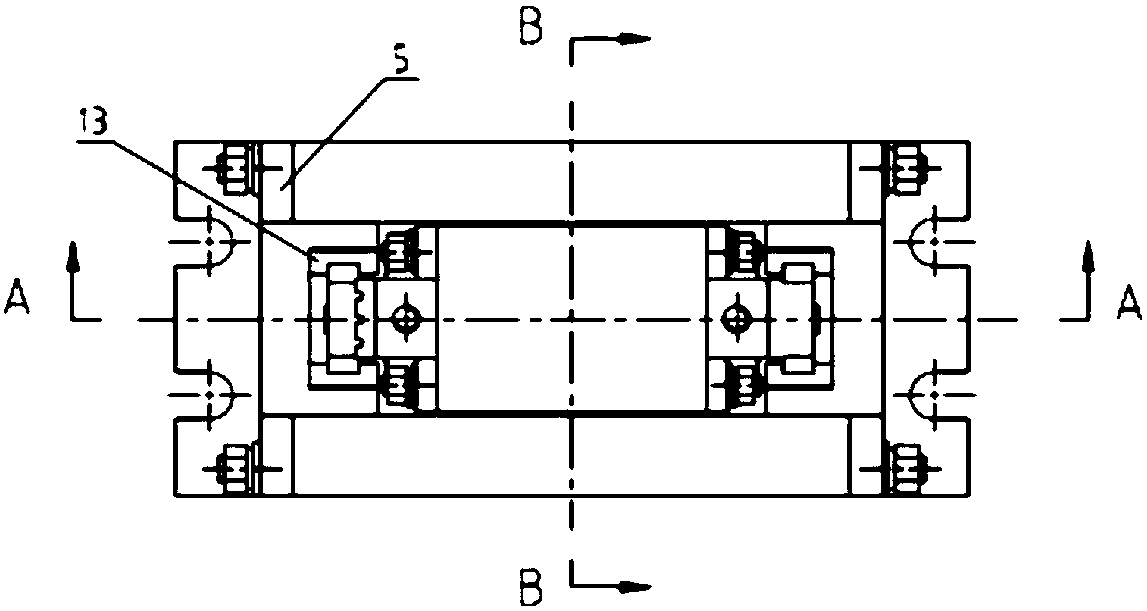

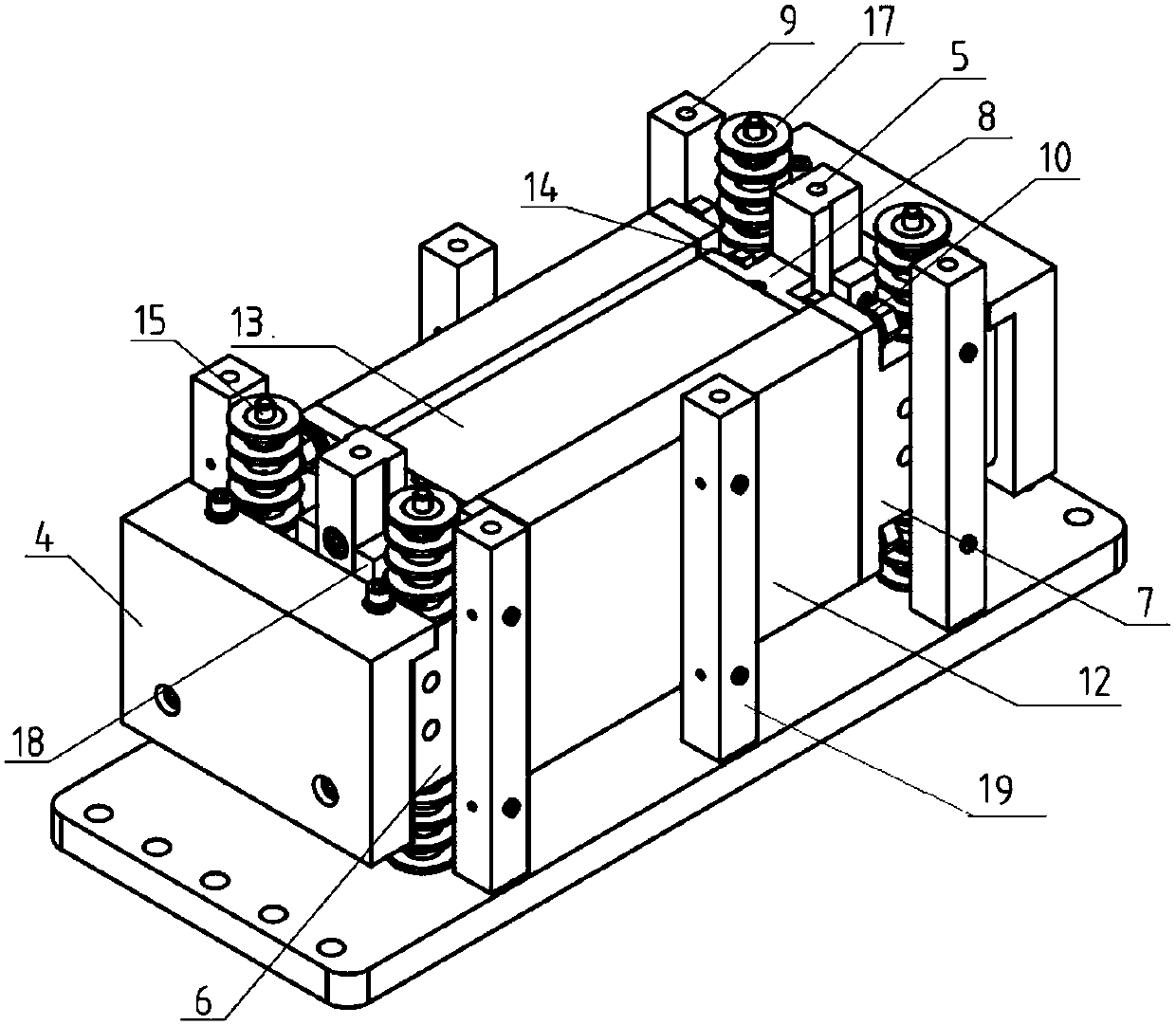

Magnetic resistance type electromagnetic active vibration absorber

ActiveCN106286666AOverall small sizeSmall qualityVibration dampersMagnetic springsNoise controlStator coil

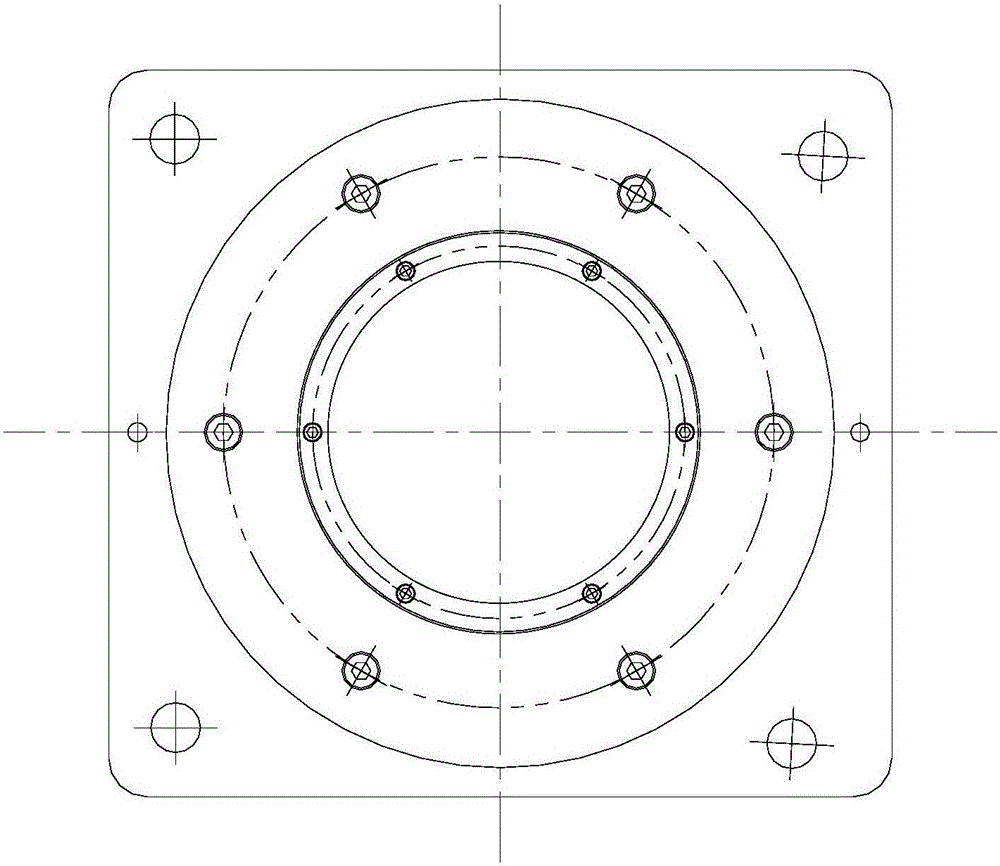

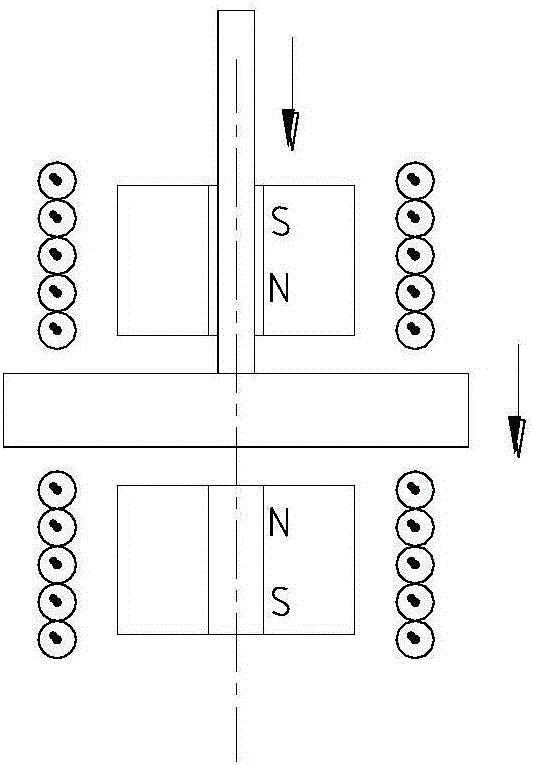

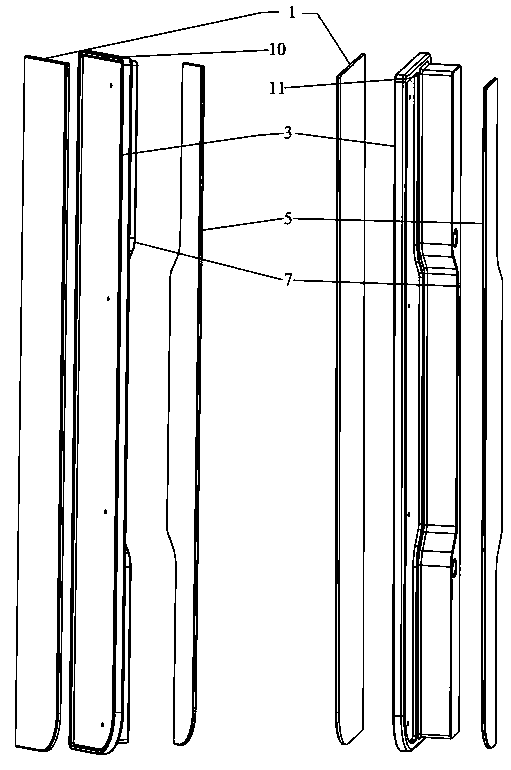

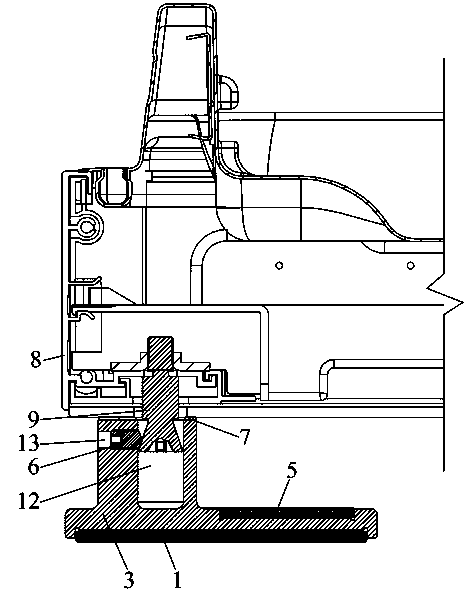

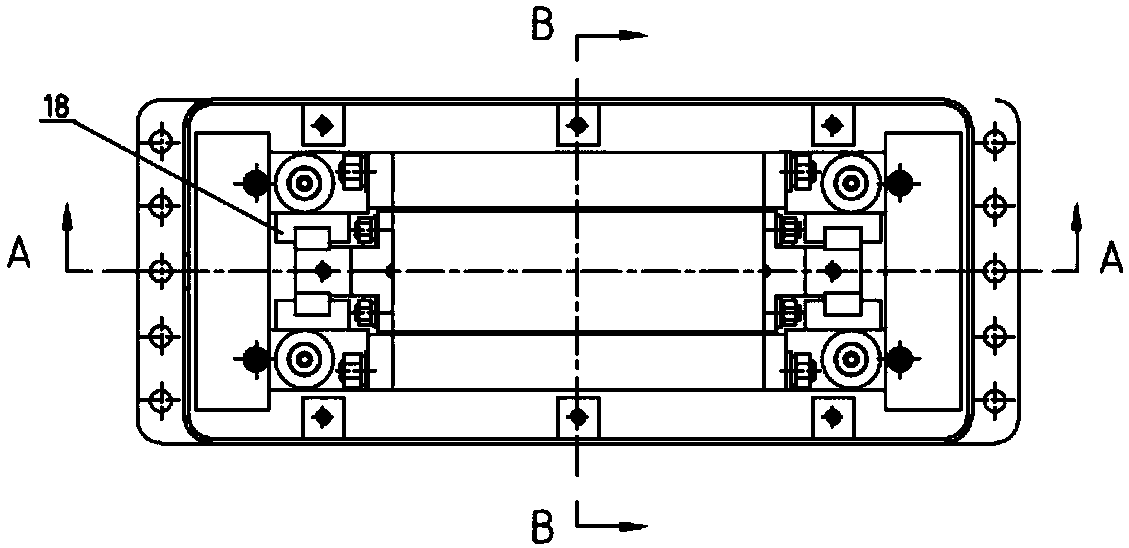

The invention belongs to the technical field of vibration noise control and particularly relates to an active vibration absorber. The magnetic resistance type electromagnetic active vibration absorber comprises a vibration absorber lower installation plate, a vibration absorber cover, a vibration absorber upper installation plate, a rotor assembly and a stator assembly. Four rolling guide rail pairs are installed between the rotor assembly and the stator assembly. The rotor assembly is connected with the vibration absorber lower installation plate and the vibration absorber upper installation plate through springs. The rotor assembly can freely vibrate through the rolling guide rail pairs. The magnetic resistance type electromagnetic active vibration absorber can be installed and used in combination with various types of passive vibration absorbers and can be arranged on a controlled object or a base at will, after a coil is electrified with alternating current, electromagnetic force is generated between the rotor assembly and the stator assembly, the stator coil generates Lorentz force, the resultant force of the electromagnetic force and the Lorentz force drives a vibration absorber rotor to move, the vibration absorption force generated by the vibration absorber rotor is used for offsetting the vibration of the controlled object, and the purpose of controlling vibration is achieved.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

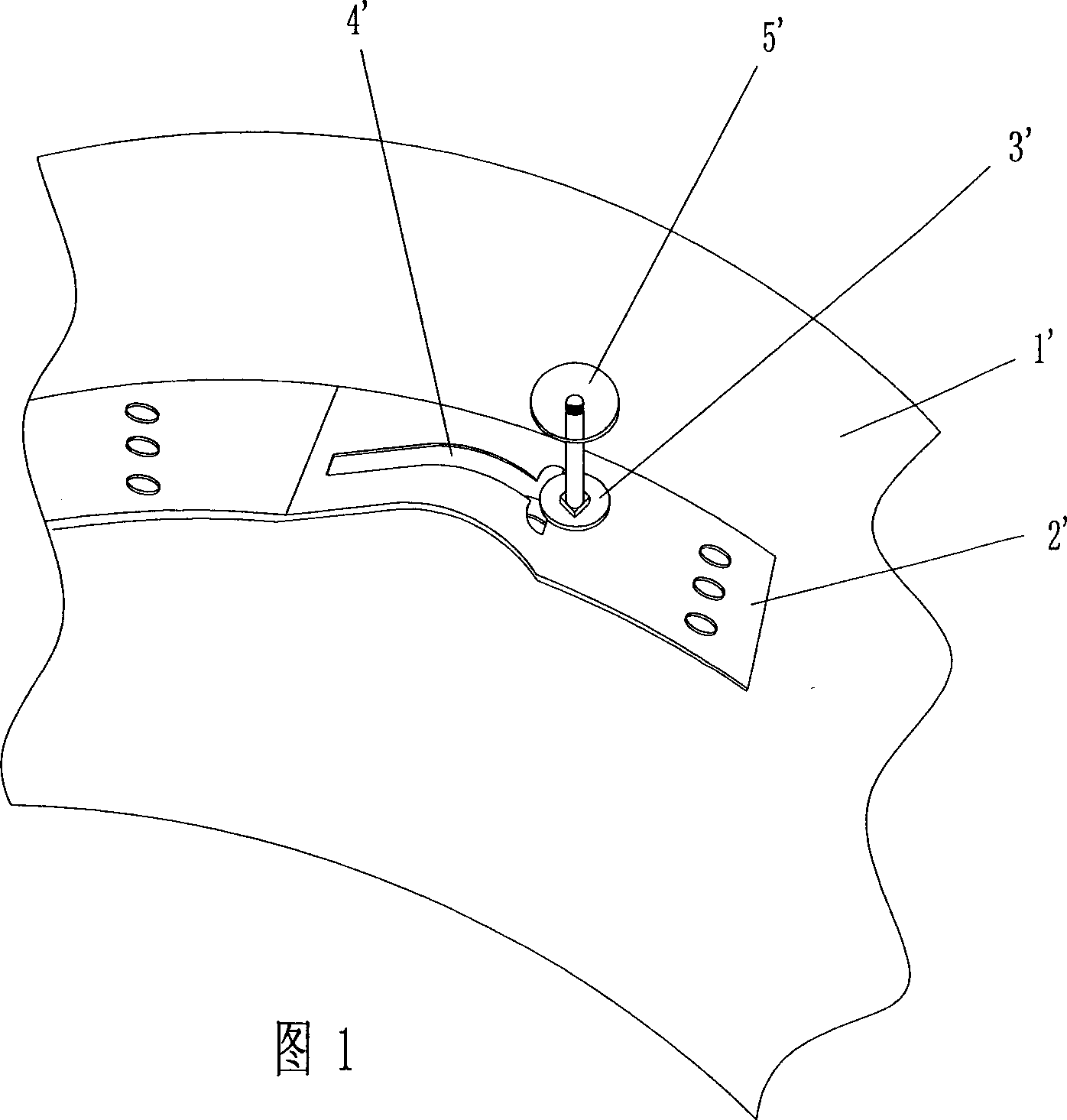

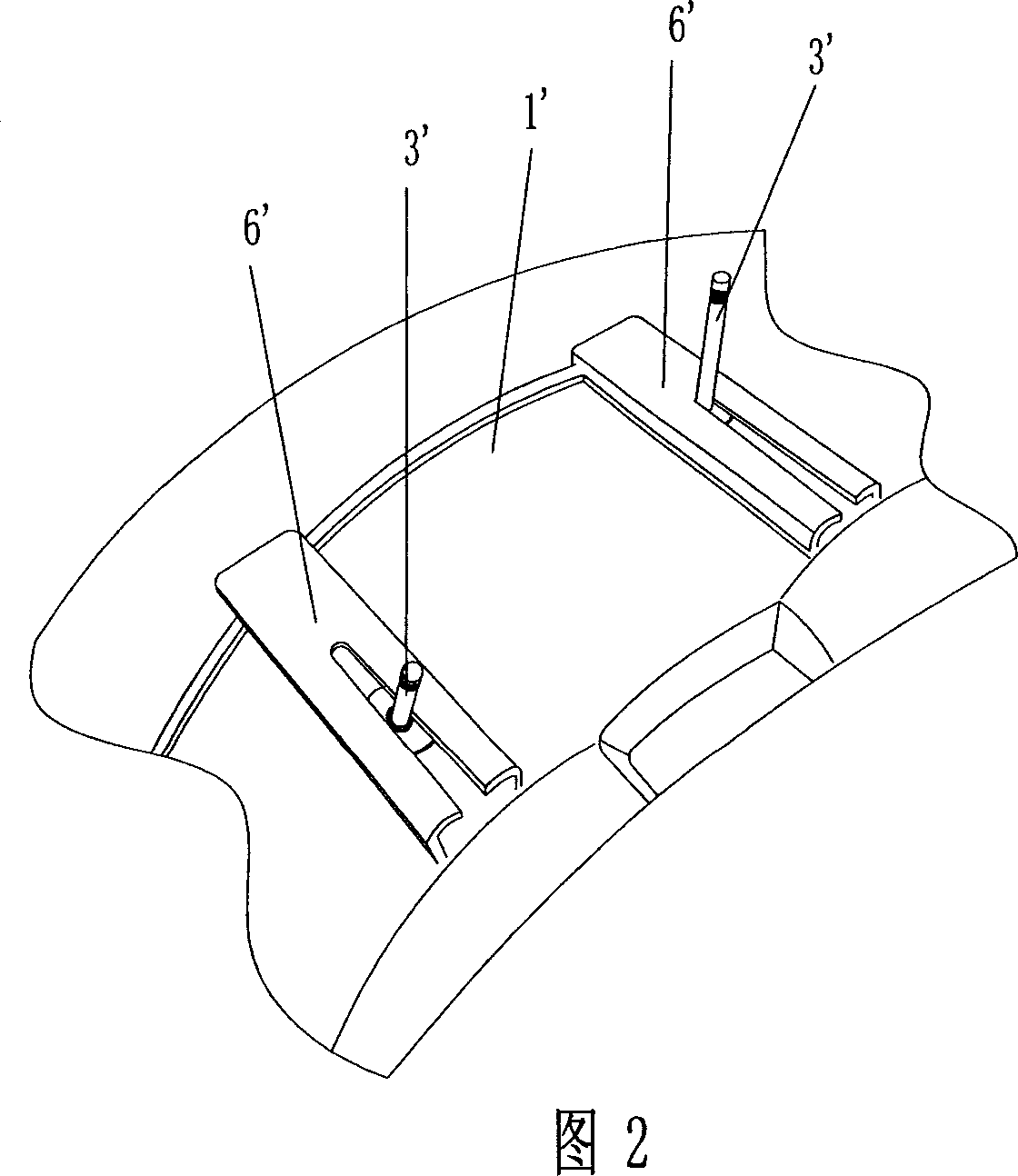

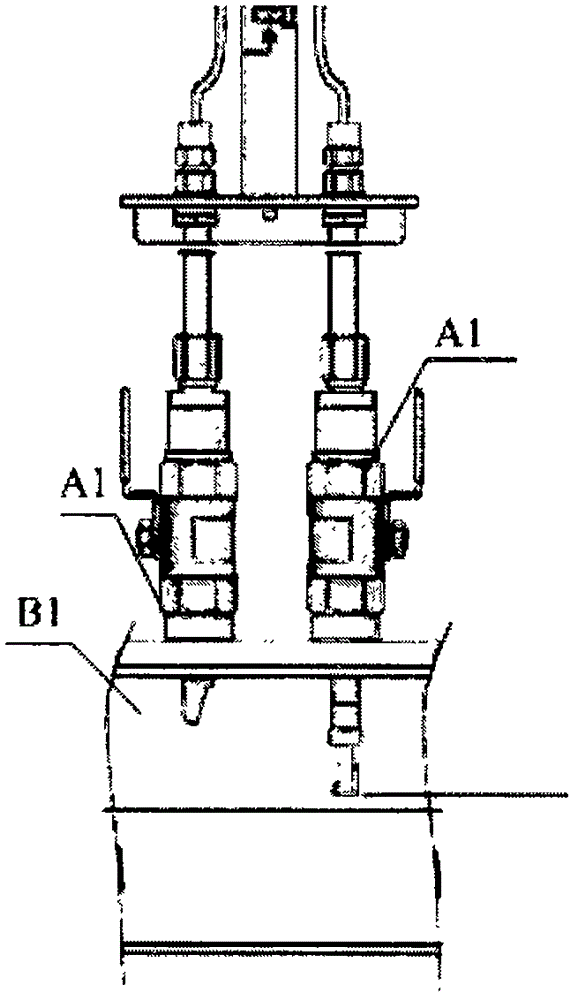

Mounting method for drum washing machine counter weight and mounting structure thereof

ActiveCN101078164AReduce settingsReduce processOther washing machinesTextiles and paperEngineeringComputer engineering

The installing method and installing configuration of match weight block for the barrel roller washing machine, its configuration consists of the outer case of the washing machine, a weight match block on which there are installing holes. There is fixed device incorporated with case for the installing of the weight match block which is installed on the fixed device through the installing holes, and the weight match block can fix on the case of the washing machine by the tighten fixed device. This invention can obtain a more convenient installing method by the replacement of the bolt device by the swell blot on the base of no changing the current configuration of the weight match block. It can save the cost, process and working intensity largely.

Owner:HAIER GRP CORP +1

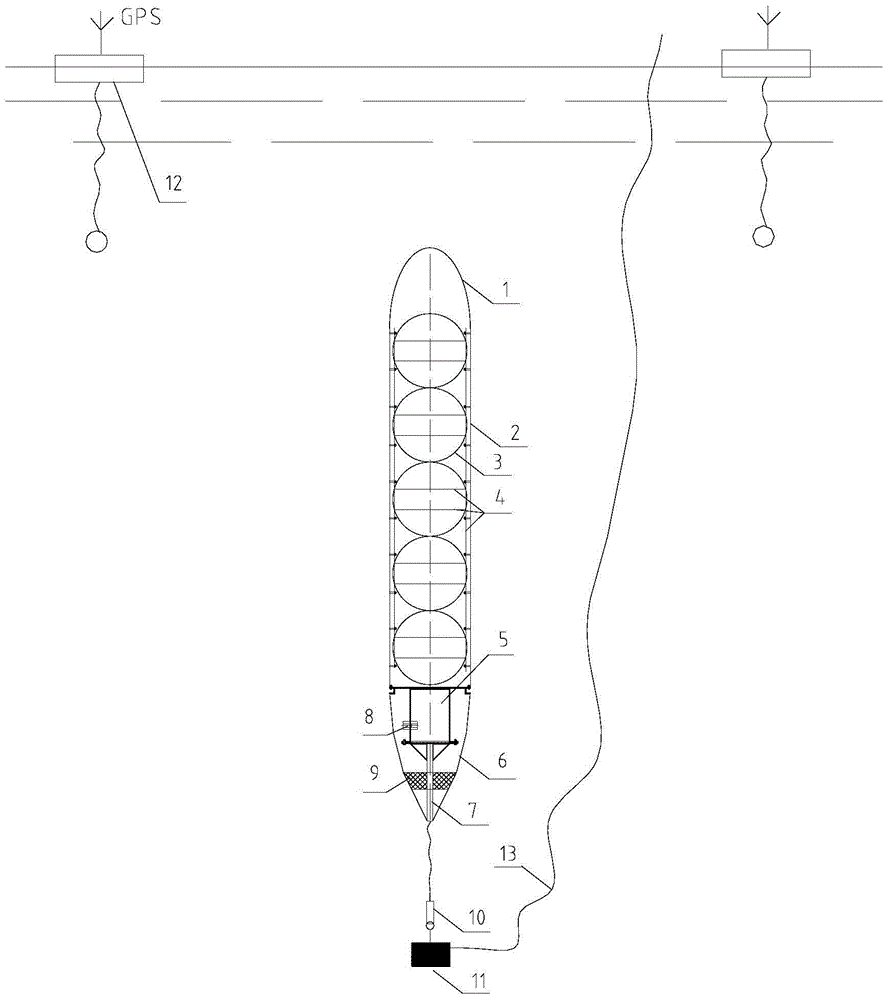

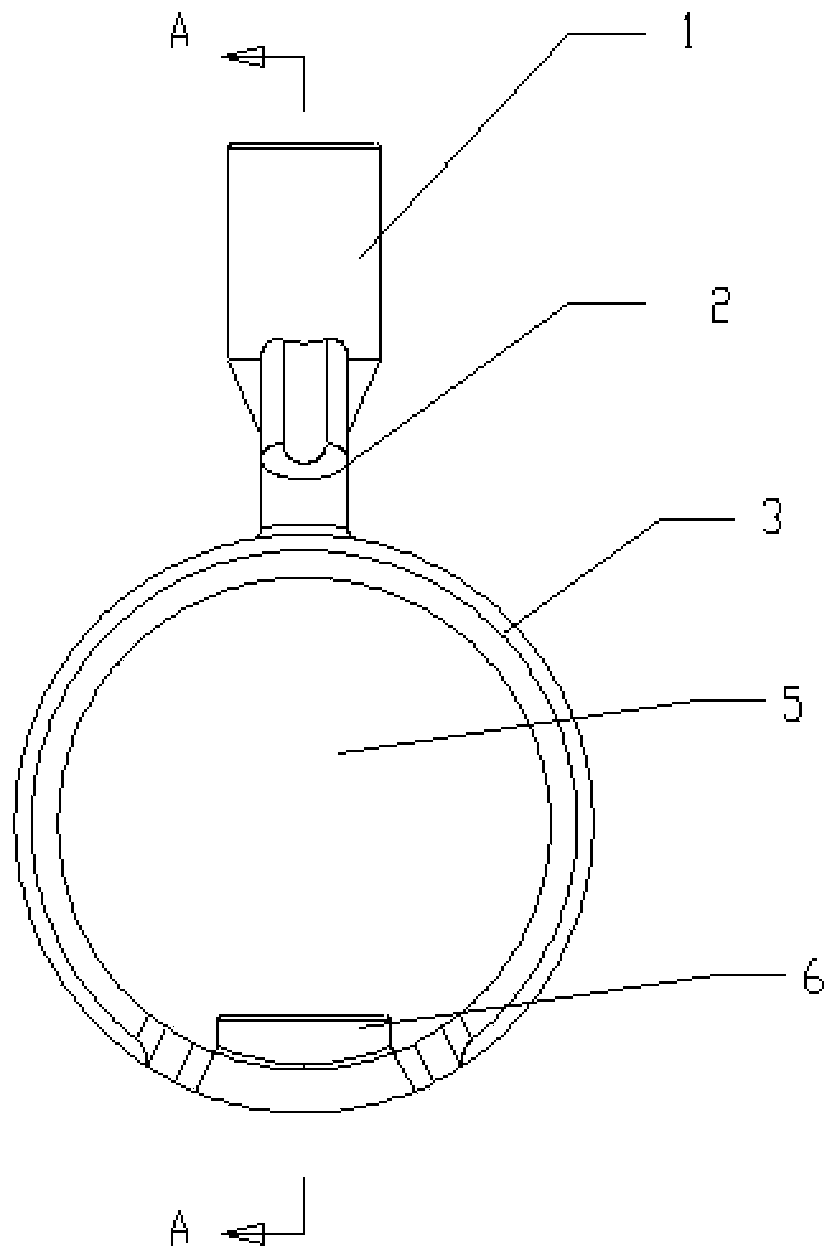

Low-noise high-navigational-speed large-depth underwater unpowered upwards-floating test platform

InactiveCN104986311ACompact and reliableReduce background noiseUnderwater equipmentSternTest platform

The invention provides a low-noise high-navigational-speed large-depth underwater unpowered upwards-floating test platform. The low-noise high-navigational-speed large-depth underwater unpowered upwards-floating test platform comprises a non-watertight outer shell, a floating force device, an electronic cabin, a release mechanism and a stern force bearing rod, wherein the floating force device is composed of a plurality of pressure withdrawing hollow floating balls and a floating ball outer frame; the non-watertight outer shell is composed of a bow end, a parallel middle body and a stern; the multiple pressure withdrawing hollow floating balls are fixedly embedded into the floating ball outer frame, and the floating ball outer frame is fixed to the interior of the parallel middle body; the electronic cabin is fixed to the interior of the stern through a flange, a sensor and a data collecting device are loaded inside the electronic cabin, and a depth sensor is loaded outside the electronic cabin; one end of the stern force bearing rod is fixedly connected to the electronic cabin, and the other end of the stern force bearing rod is fixedly connected with the tail end of the stern of the outer shell; and the release mechanism is composed of a weight and a releaser, and the weight is connected with the other end of the stern force bearing rod through the releaser. The test platform can serve as an underwater structure flow-induced near-field or a far-field noise test verification platform.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

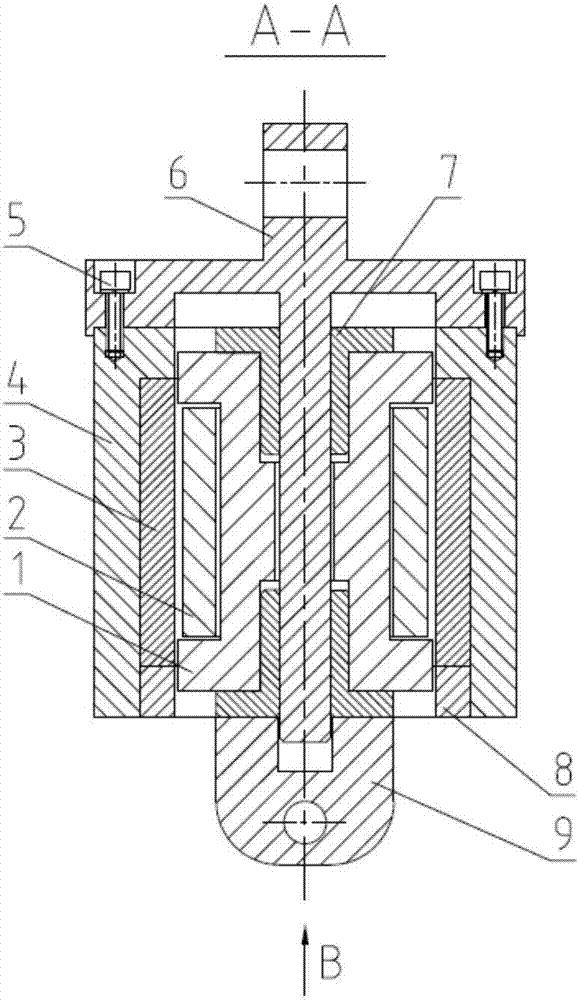

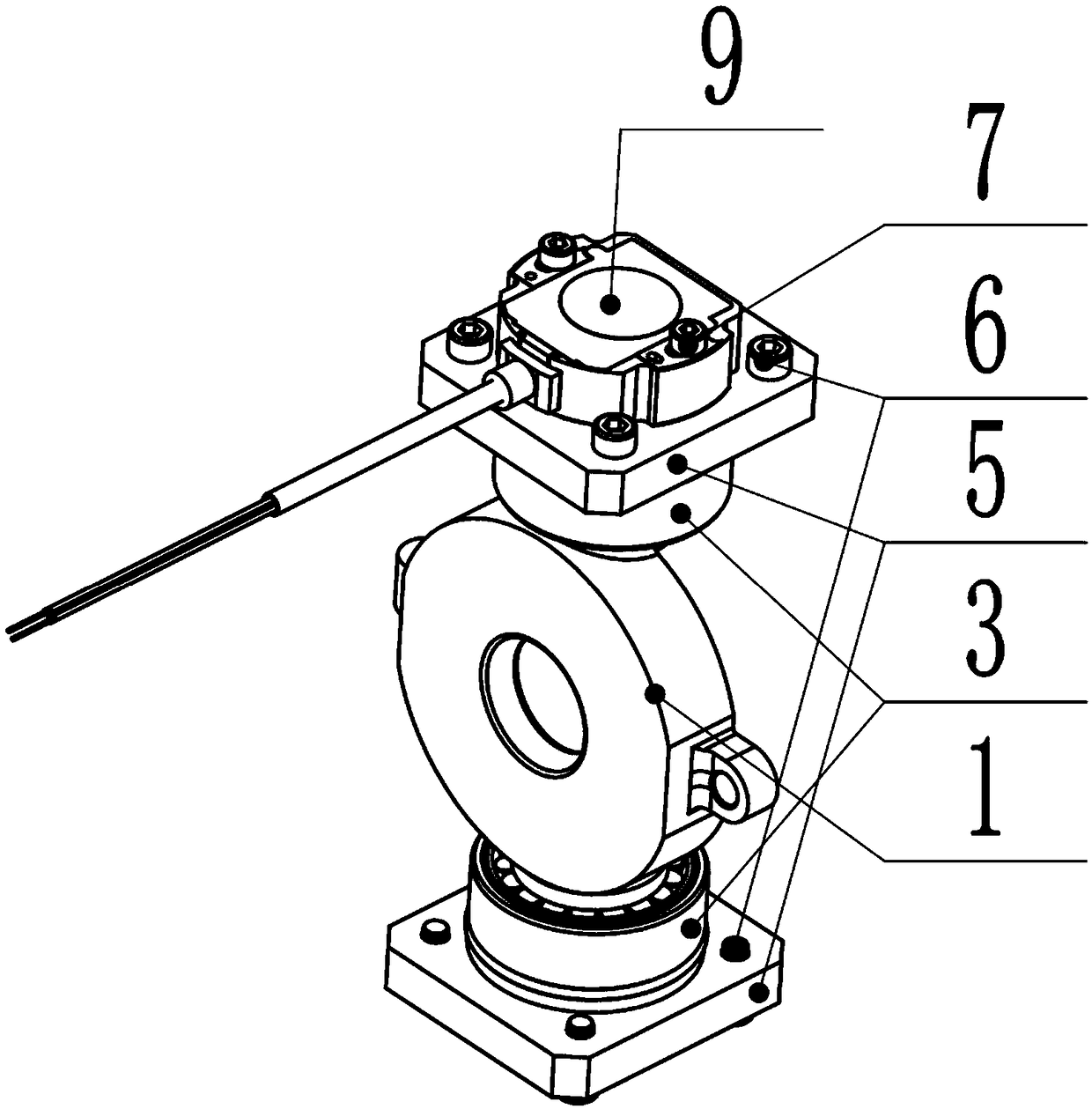

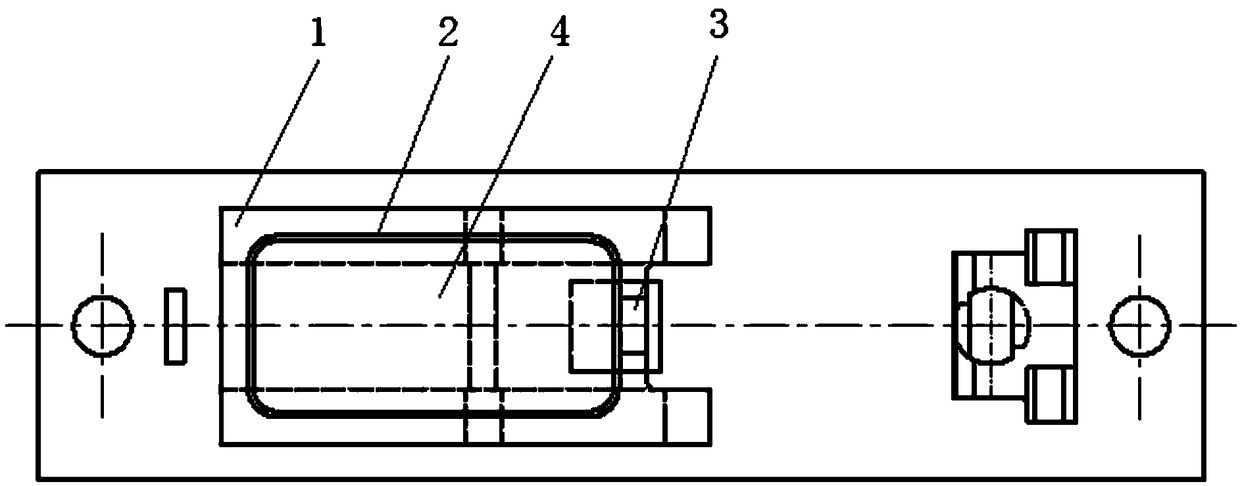

Self-inducing magnetic resistance type electromagnetic damper

PendingCN107387631AImprove output characteristicsOptimize structureVibration dampersMagnetic springsStatorEngineering

The invention discloses a self-inducing magnetic resistance type electromagnetic damper and belongs to the technical field of vibration noise control. The damper comprises a housing stator assembly and an internal active cell assembly, wherein the housing stator assembly and the internal active cell assembly are assembled together, the internal active cell assembly freely moves with respect to the housing stator assembly, a soft magnetic metal magnet yoke and a coil in the internal active cell assembly move in a magnetic field produced by the housing stator assembly, respectively produce eddy current and a Lorentz force hindering cutting magnetic induction line motion of the coil and meanwhile produce an electromagnetic force hindering cutting magnetic induction line motion of the soft magnetic metal magnet yoke, and the electromagnetic force is far greater than the Lorentz force. The damper can output lots of damping forces greater than a traditional electromagnetic damper, meanwhile has good anti-swing and anti-impact performance and has very high engineering applicability.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

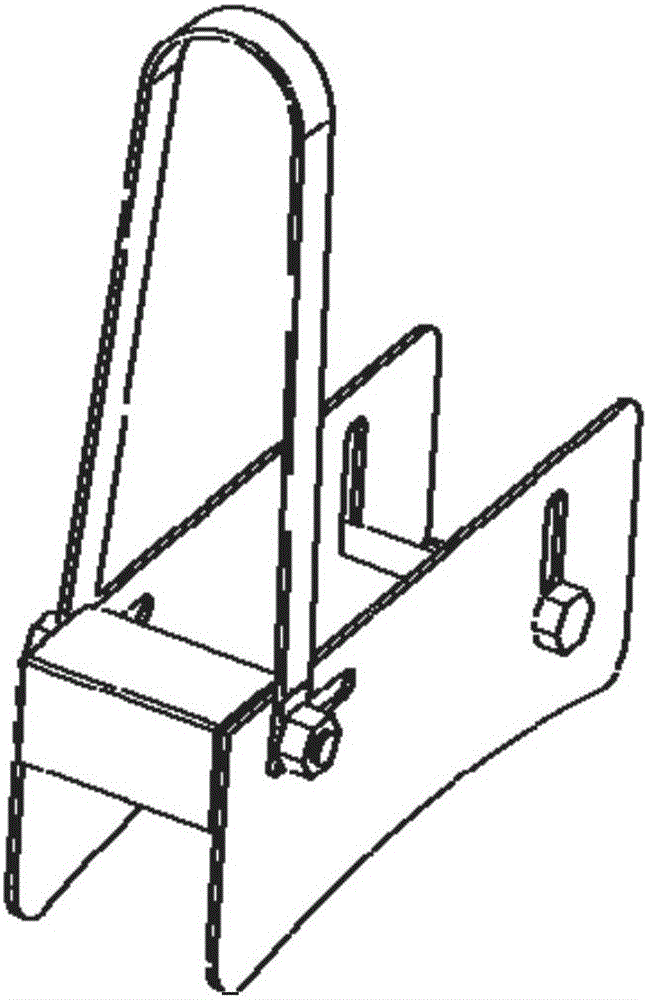

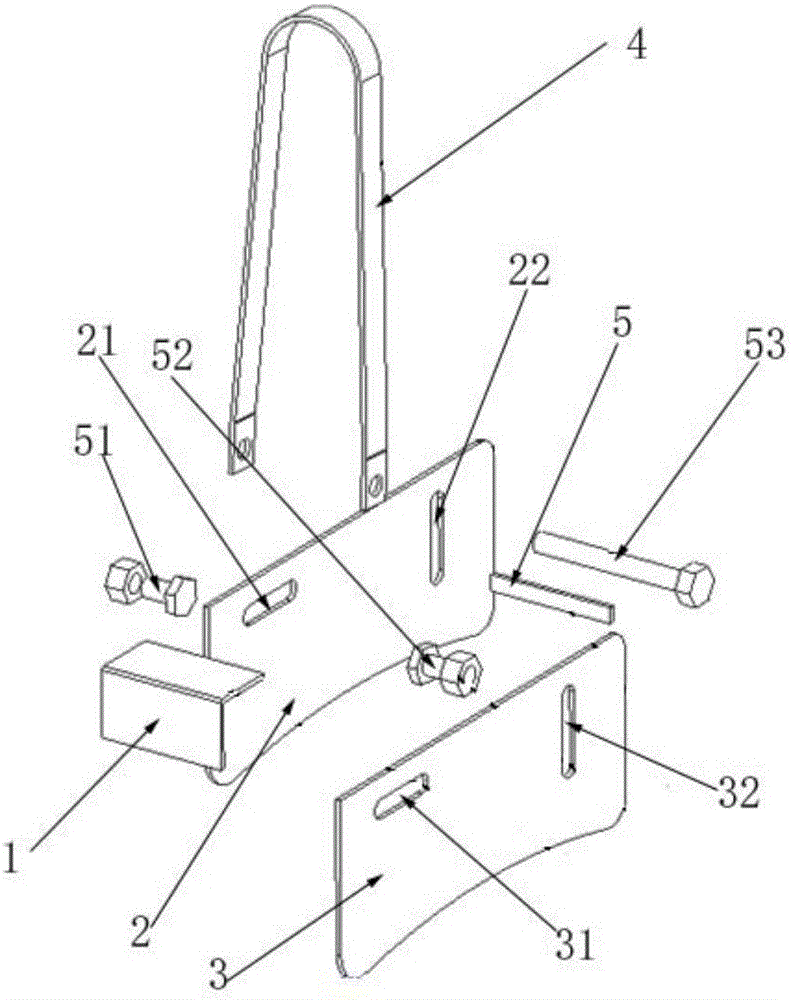

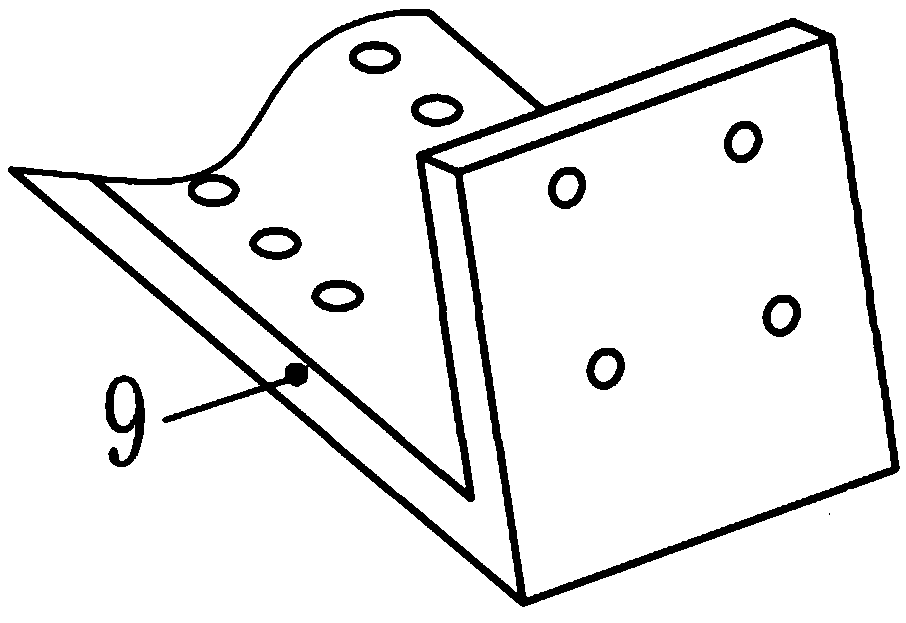

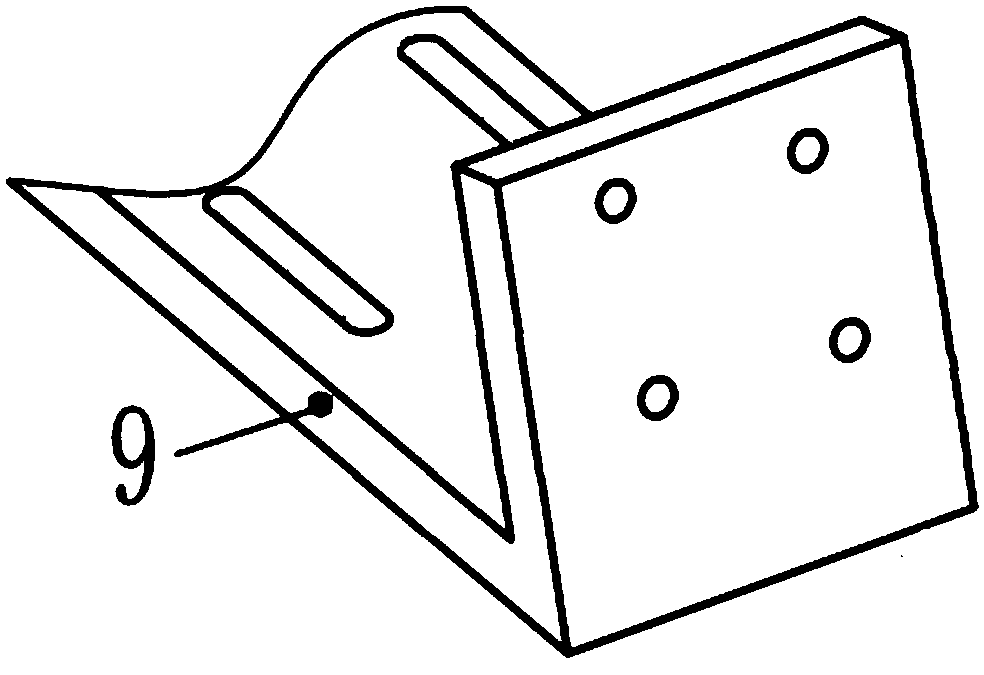

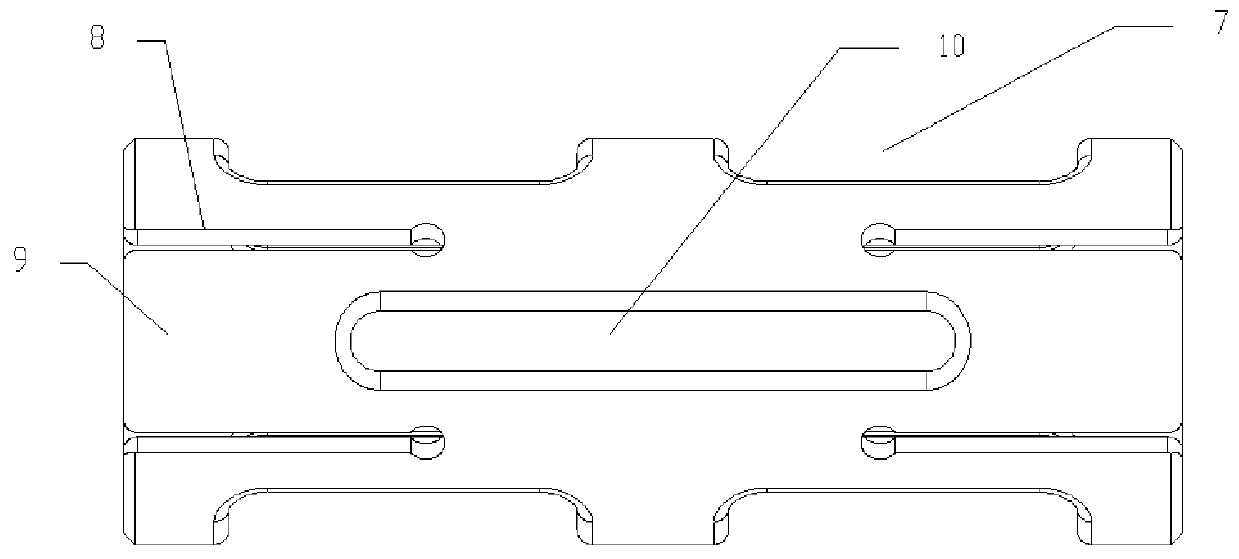

Welding-slag splashing prevention device

The invention provides a welding-slag splashing prevention device. The welding-slag splashing prevention device comprises a front baffle, a first lateral baffle, a second lateral baffle and a hook, wherein the front baffle is located at the front end of the first lateral baffle and the front end of the second lateral baffle and fixed between the first lateral baffle and the second lateral baffle; the hook is in an inverse-U shape, the top end of the hook is mounted on a welding gun, and the hook can move along with the welding gun to drive the whole welding-slag splashing prevention device to move on the surface of a welded workpiece; and the two open ends of the inverse-U-shaped hook are mounted on the front portion of the first lateral baffle and the front portion of the second lateral baffle correspondingly. The welding-slag splashing prevention device provided by the invention is designed according to the structure of the welding gun, the mounting mode is simple and reliable, the device can be reliably positioned only through studs, the positioning mode is simple, and the cost is low; and meanwhile, through matched installation of the studs, the hook and kidney-shaped grooves, the device can be adjusted according to the specific position of the welding gun, and the device can adapt to welding-slag splashing prevention of welding of inner containers with different diameters and at different heights by adjusting the positions of the studs.

Owner:GREE ELECTRIC APPLIANCES INC

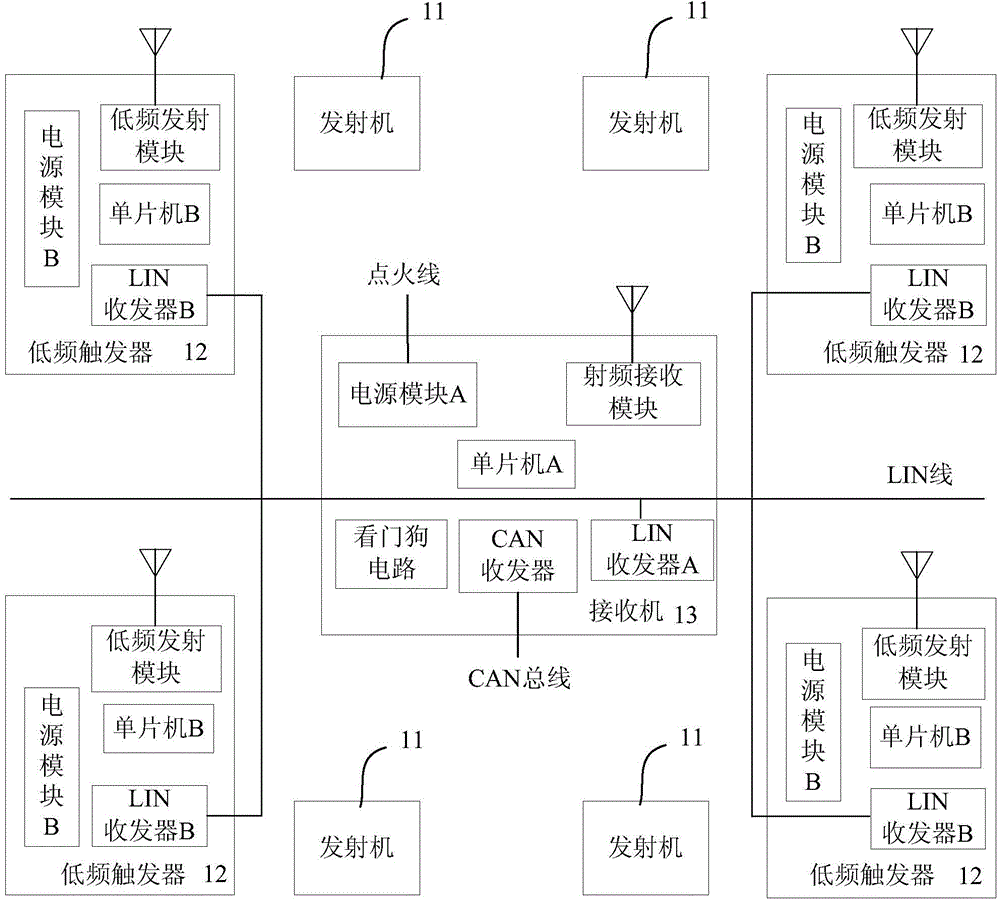

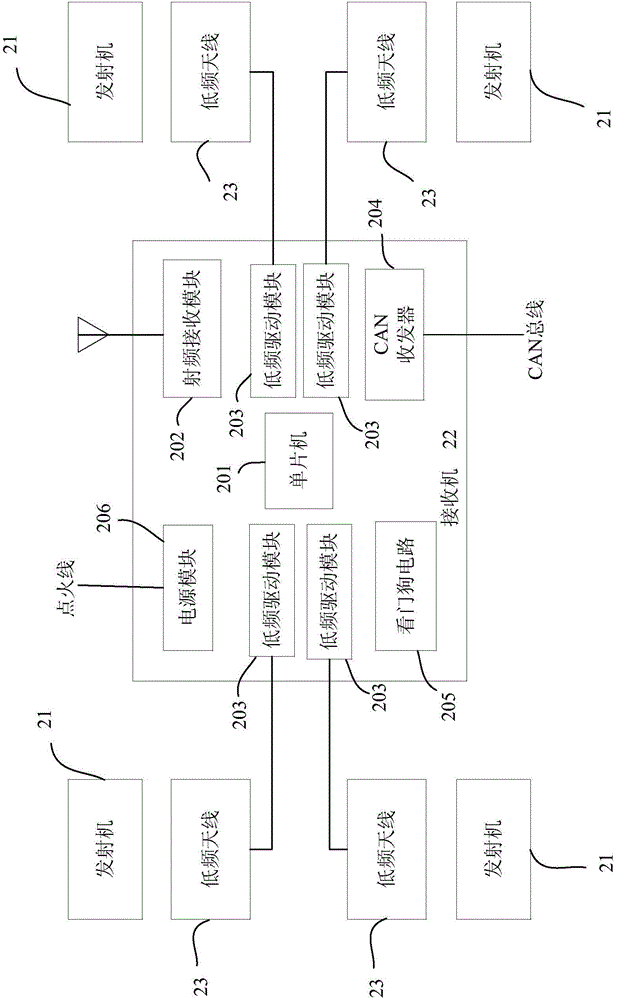

Two-way communication tire pressure monitoring system

InactiveCN104553635AReduce volumeReduce weightTyre measurementsTire-pressure monitoring systemTwo-way communication

The invention relates to a two-way communication tire pressure monitoring system. The two-way communication tire pressure monitoring system comprises a plurality of transmitters, a plurality of low-frequency antennas and a receiver, wherein a plurality of transmitters are fixed on an automobile rim respectively, each transmitter comprises a low-frequency receiving module for receiving a low-frequency wake-up signal; a plurality of low-frequency antennas are used for transmitting all low-frequency wake-up signals respectively; the receiver is arranged inside an automobile body and comprises one or more low-frequency driving modules which are connected with all low-frequency antennas in a wired manner for outputting all low-frequency wake-up signals to all low-frequency antennas respectively.

Owner:SHANGHAI BAOLONG AUTOMOTIVE CORP

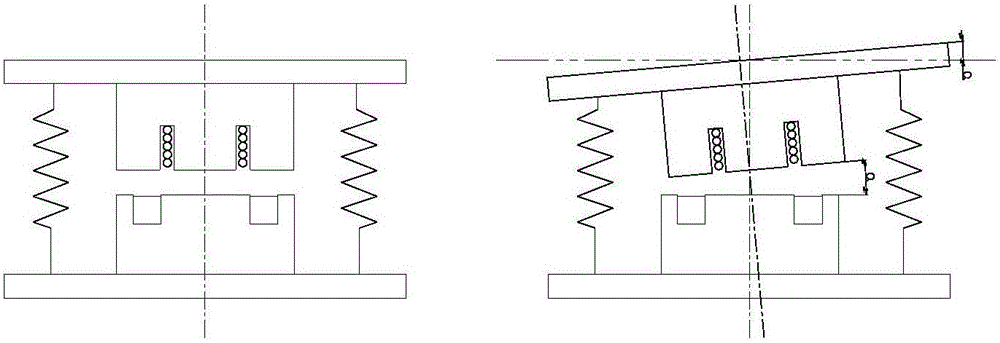

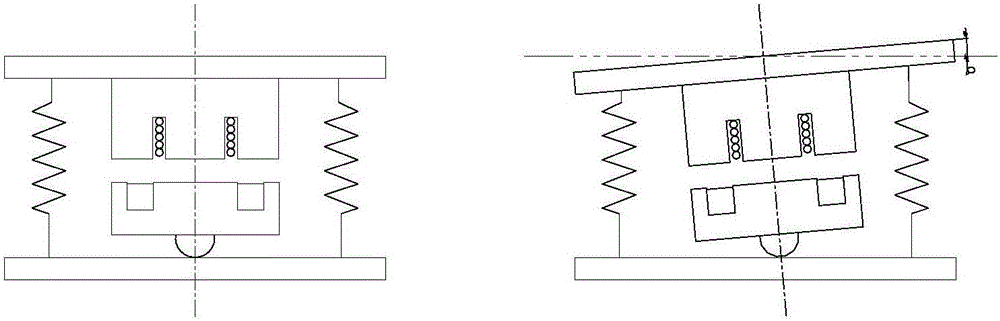

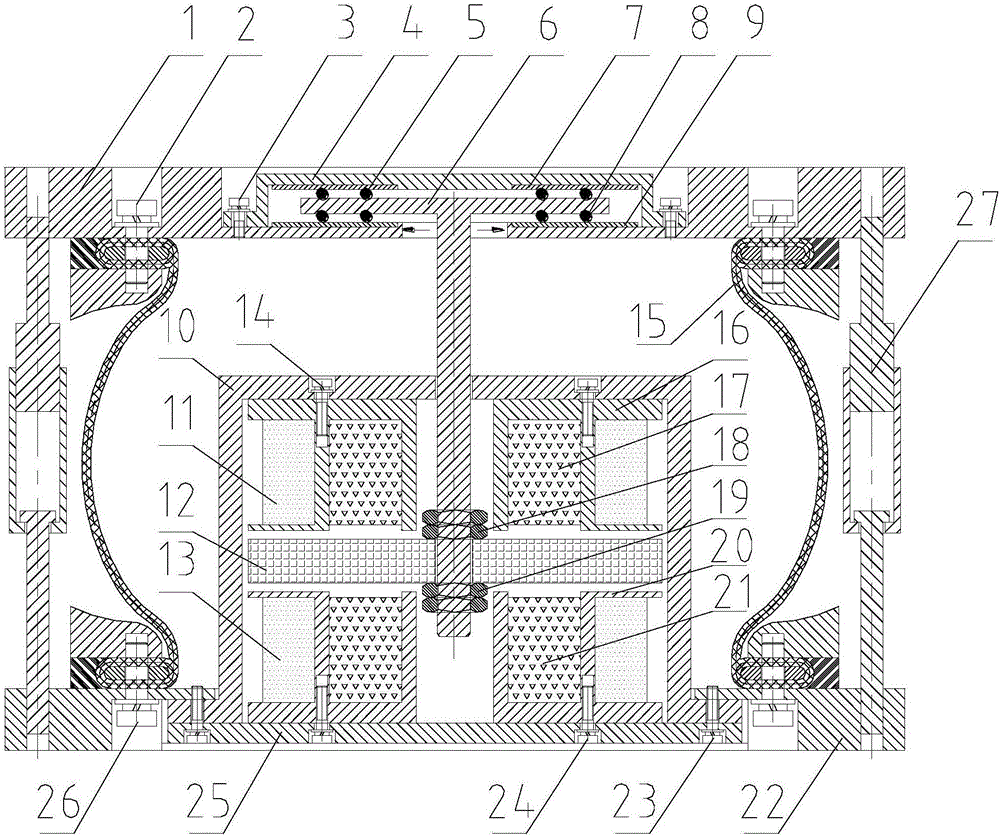

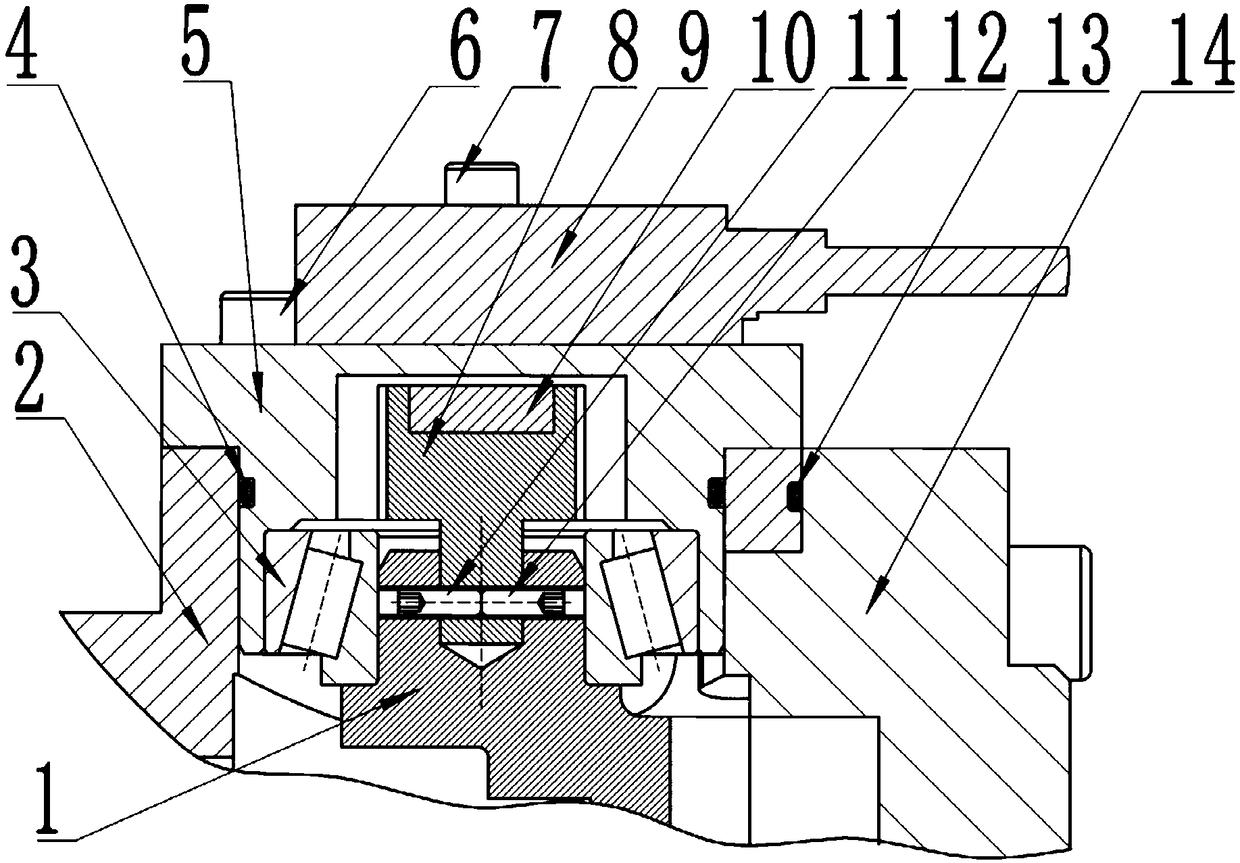

Swing-resistant electromagnetic hybrid active actuation mechanism

InactiveCN105927701ASuppression of medium and high frequency vibrationAvoid stuck phenomenonPivotal connectionsVibration suppression adjustmentsNoise controlElectricity

The invention belongs to the technical field of vibration noise control, and particularly relates to a vibration active control technology. According to the technical scheme of a swing-resistant electromagnetic hybrid active actuation mechanism, a passive vibration isolator is composed of an upper cover plate, an airbag damper bag body, a lower cover plate and shell locking bolts and is used for suppressing medium-high frequency vibration of a controlled object; an active actuation mechanism body is composed of an upper armature, a middle armature, a lower armature, circular permanent magnets, annular permanent magnets, coil windings, a coil retainer, a middle screw, a fixing screw and a linear bearing; The permanent magnets and the armatures form a magnetic channel; current coils cut magnetic lines of force in the magnetic channel to generate electromagnetic force; and the distance between the upper permanent magnet and the coil windings is equal to the distance between the lower permanent magnet and the coil windings, so that it is ensured that the average magnetic field strength in the coils of the middle armature driven by the electromagnetic force is consistent, the magnitude of output force does not change with changes of strokes of the middle armature, and nonlinearity is avoided. It is ensured that the output force of the active actuation mechanism is normal when controlled equipment inclines or swings, and the stuck stagnation phenomenon of a conventional actuation mechanism is avoided.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

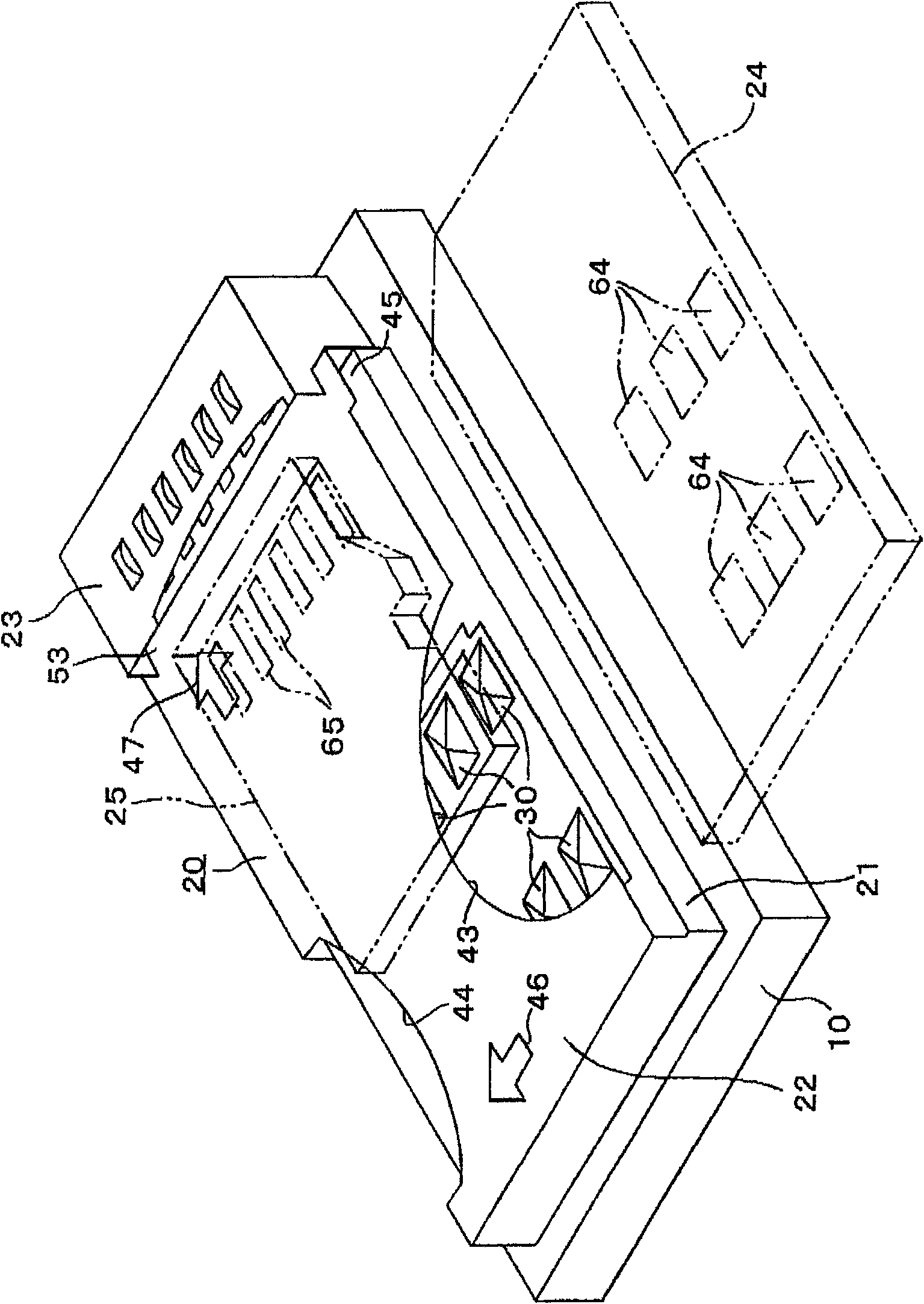

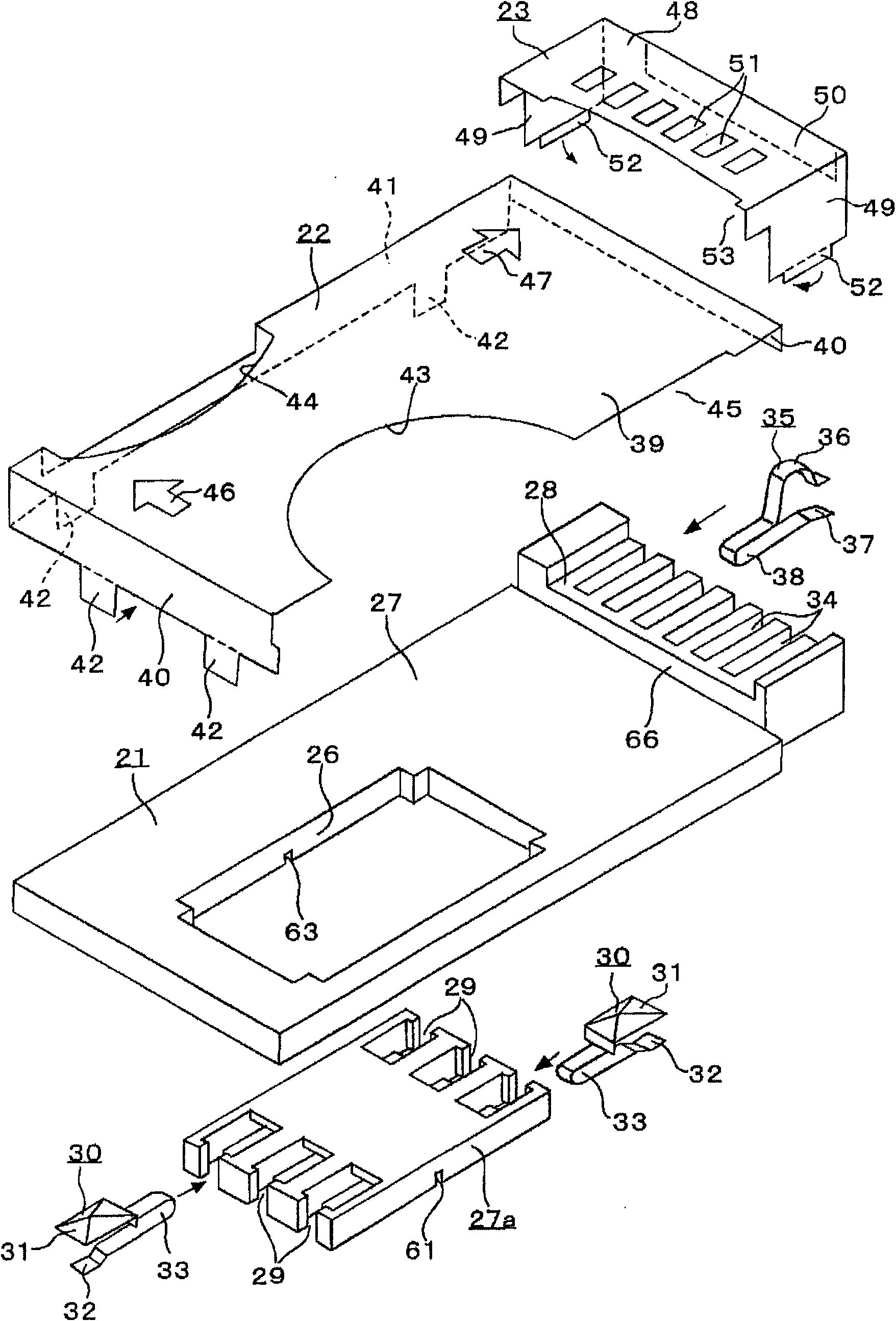

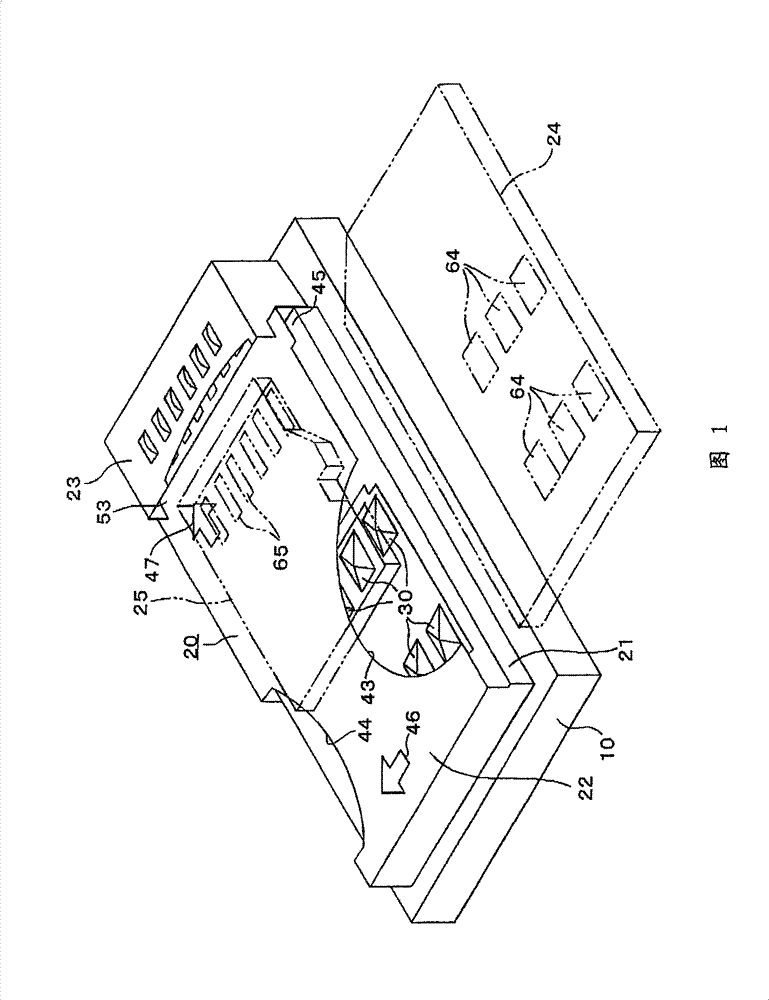

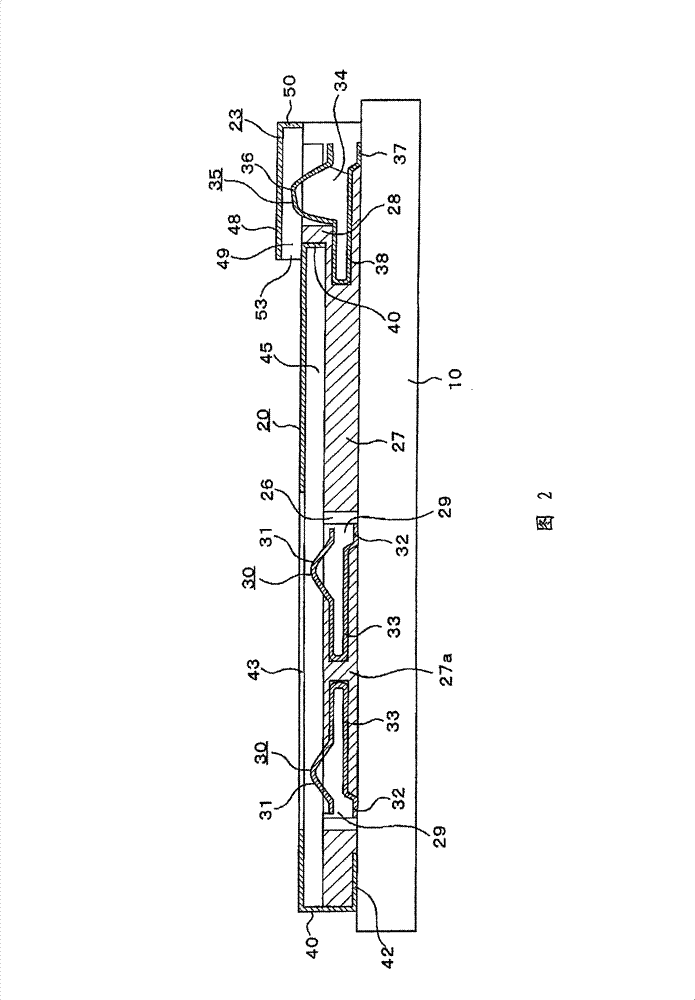

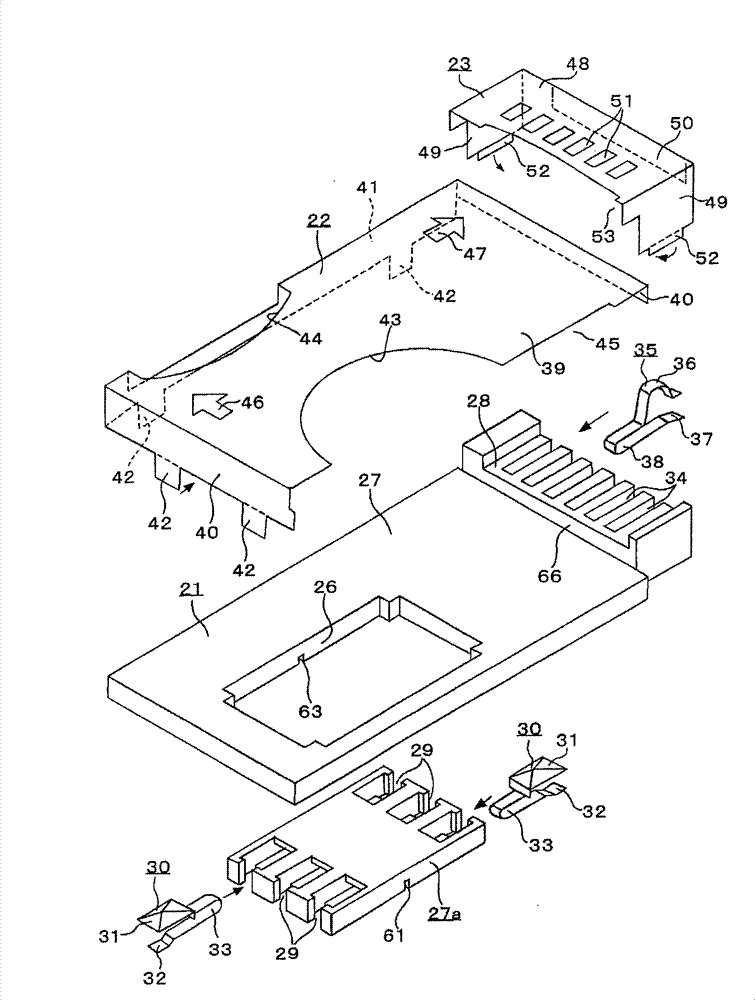

Composite connector for memory cards

InactiveCN101577381AReduce shareEasy to assembleCoupling device connectionsSensing record carriersMemory cardsComputer science

The invention provides a composite connector which reduces occupied portion of a substrate caused by a plurality of memory cards related to the carried substrate. The composite connector of the invention has at least a card insertion opening where a first and a second memory card (24, 25) can be plugged on a body (21). The body (21) has a first body (27) for connection and a second body (28) for connection connected with an edge of the first body (27) for connection. On the first body (27) for connection, a first card conductive cover (22) is covered by way of forming a first card insertion opening (45) and on the second body (28) for connection, a second card conductive cover (23) is covered by way of forming a second card insertion opening (53). Outer side surface of the first card conductive cover (22) is used as a slide surface of the second memory card (25) so that the slide surface faces the second card insertion opening (53).

Owner:SMK CO LTD

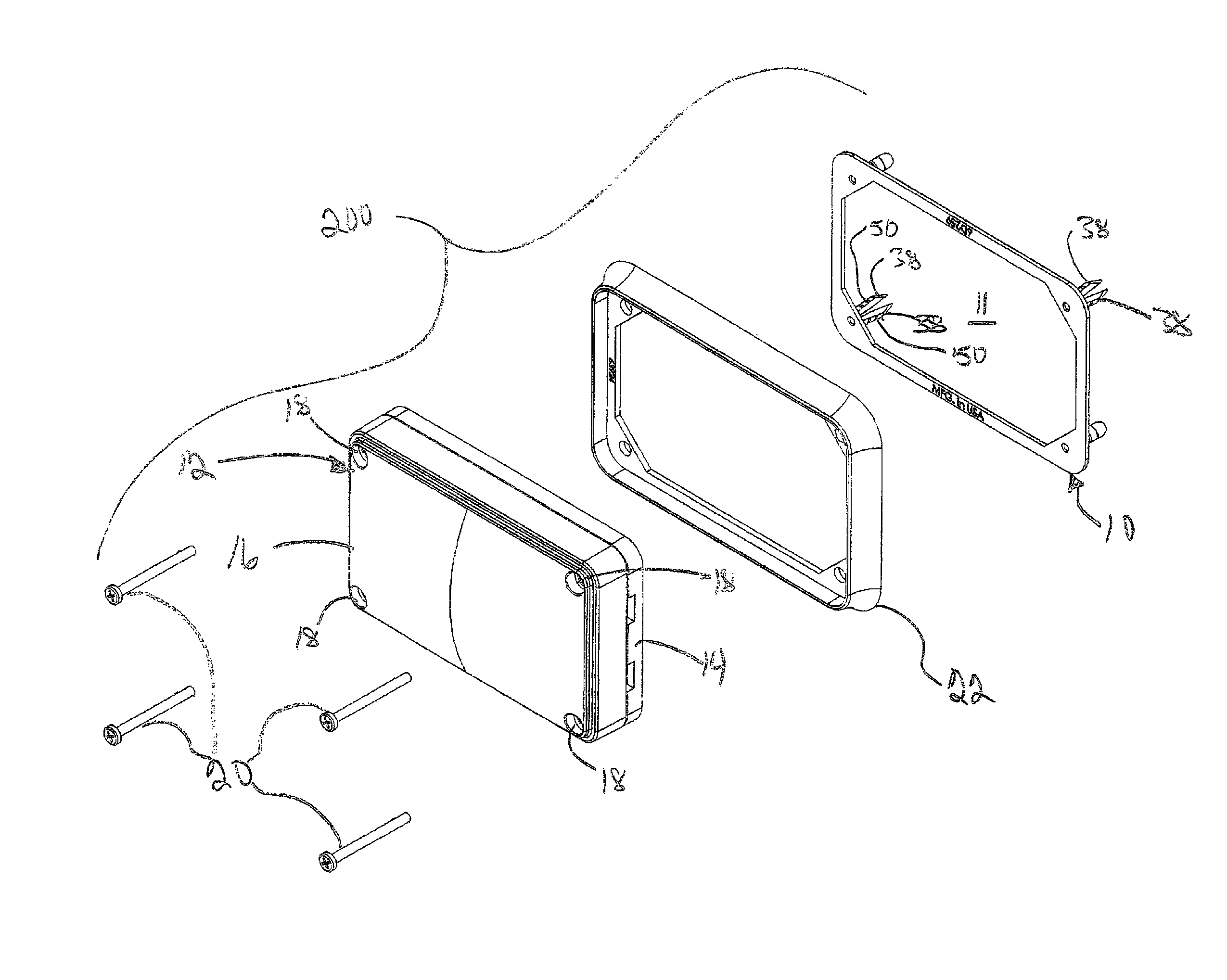

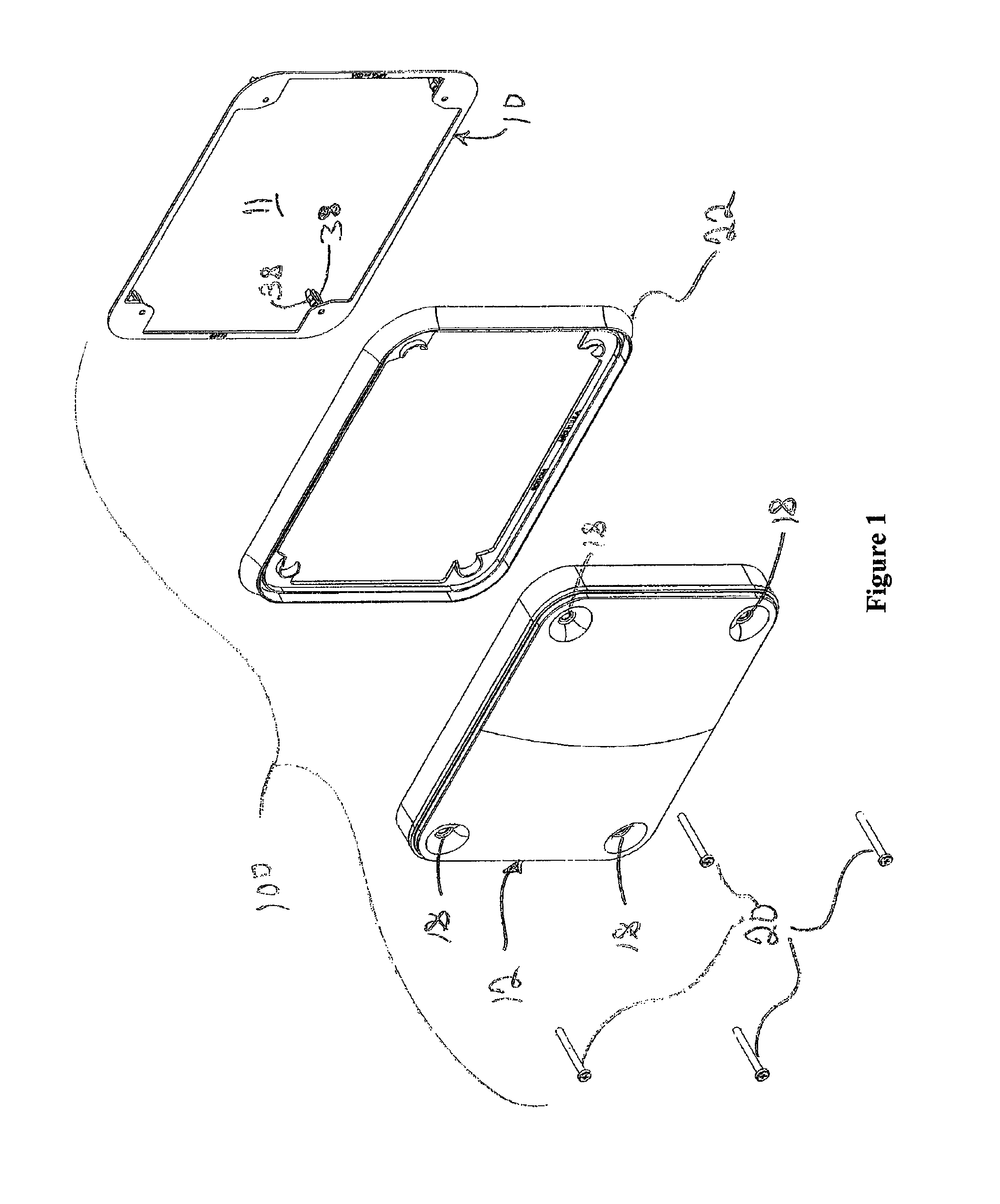

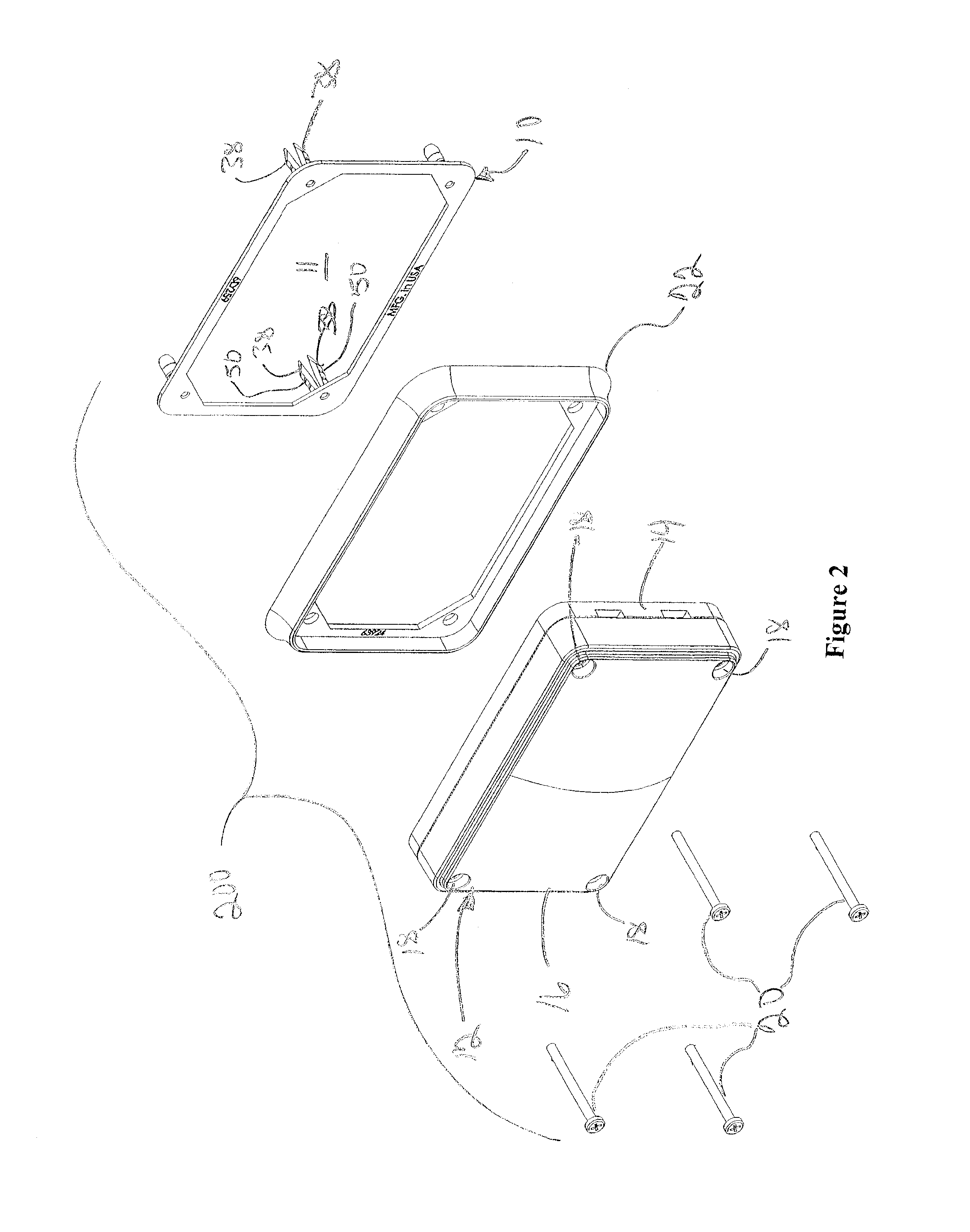

Warning light frame with integral screw anchors

ActiveUS8833993B1Easy to insertEasy to installPortable emergency signal deviceLighting support devicesSupport surfaceFastener

A warning light assembly includes a frame with integral fastener anchors. The frame aligns and supports the anchors with openings in a vehicle body or other support surface. Fasteners pass through a warning light housing to spread retention legs behind the support surface. The anchors are connected by the frame and cannot rotate relative to the vehicle body or warning light. The frame defines a central opening for warning lights requiring additional depth.

Owner:WHELEN ENGINEERING COMPANY

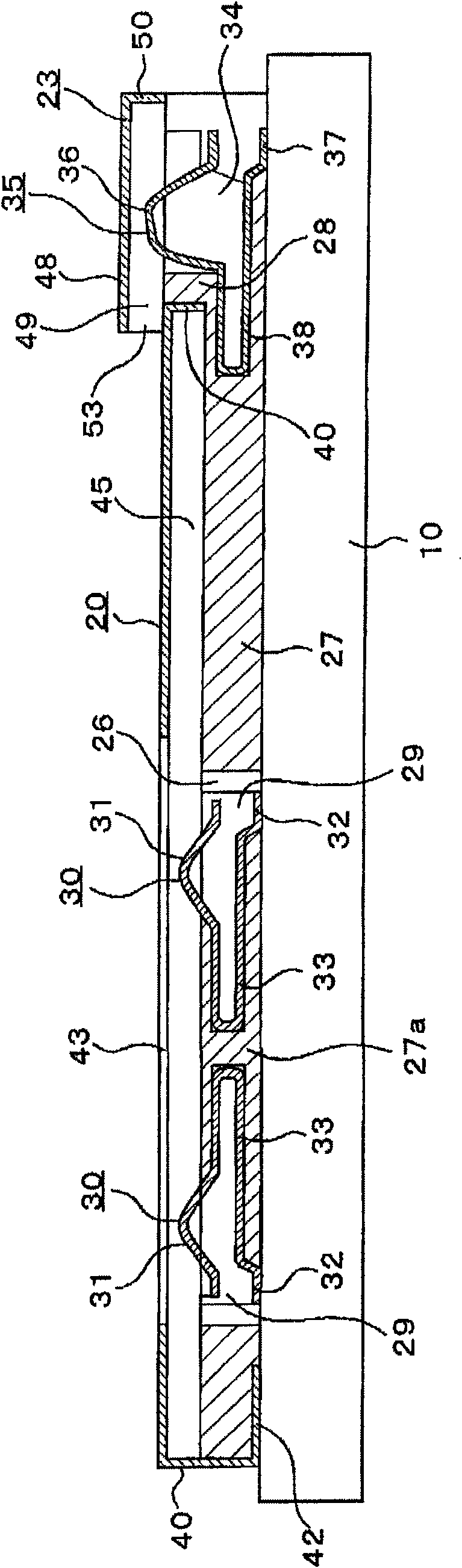

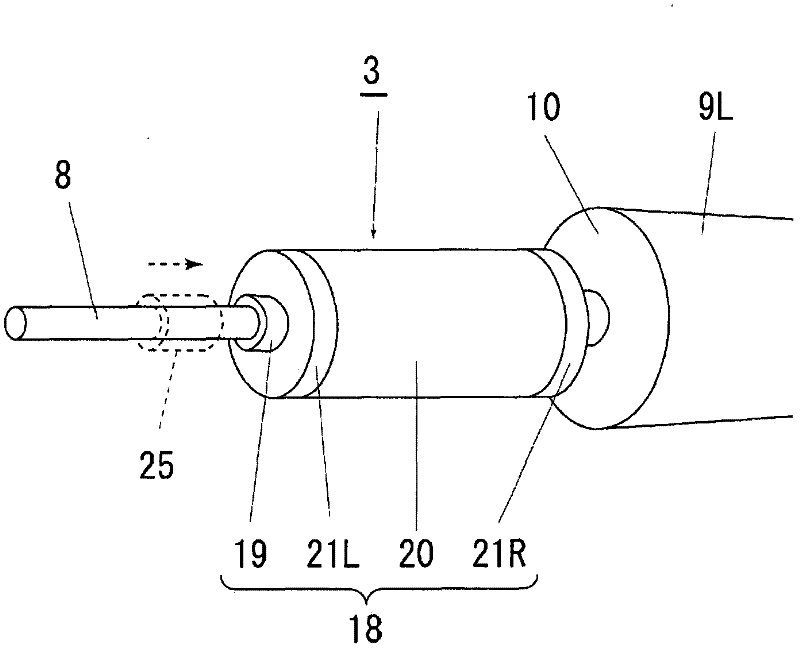

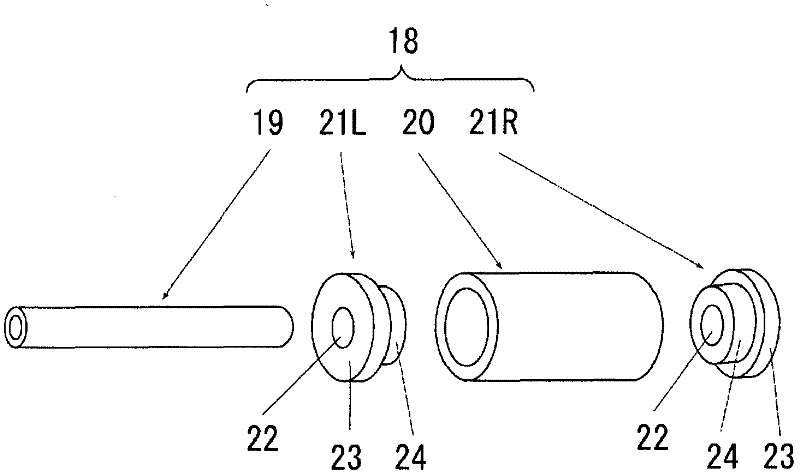

Light-source device

InactiveCN102395827AEfficient irradiationReduce manufacturing costPoint-like light sourceElectric lightingNoble gasEffect light

Provided is a startup-assist light source that has a simple structure, keeping the manufacturing cost down, and can easily and reliably be mounted at a location from which ultraviolet light can be efficiently emitted toward the discharge envelope of a high-pressure discharge lamp, said ultraviolet light improving the startup characteristics of the lamp without heating the lamp to a high temperature upon lighting. The startup-assist light source (3) has a translucent airtight envelope (18) filled with a noble gas, said envelope provided with a pipe section (19) going through said envelope. The pipe section (19) is mounted to an electrode lead (8) which goes through the pipe section and protrudes from the end surface (10) of an electrode sealing part (9L) fixed in a bottom hole (14) of a concave reflective mirror (2).

Owner:IWASAKI ELECTRIC CO LTD

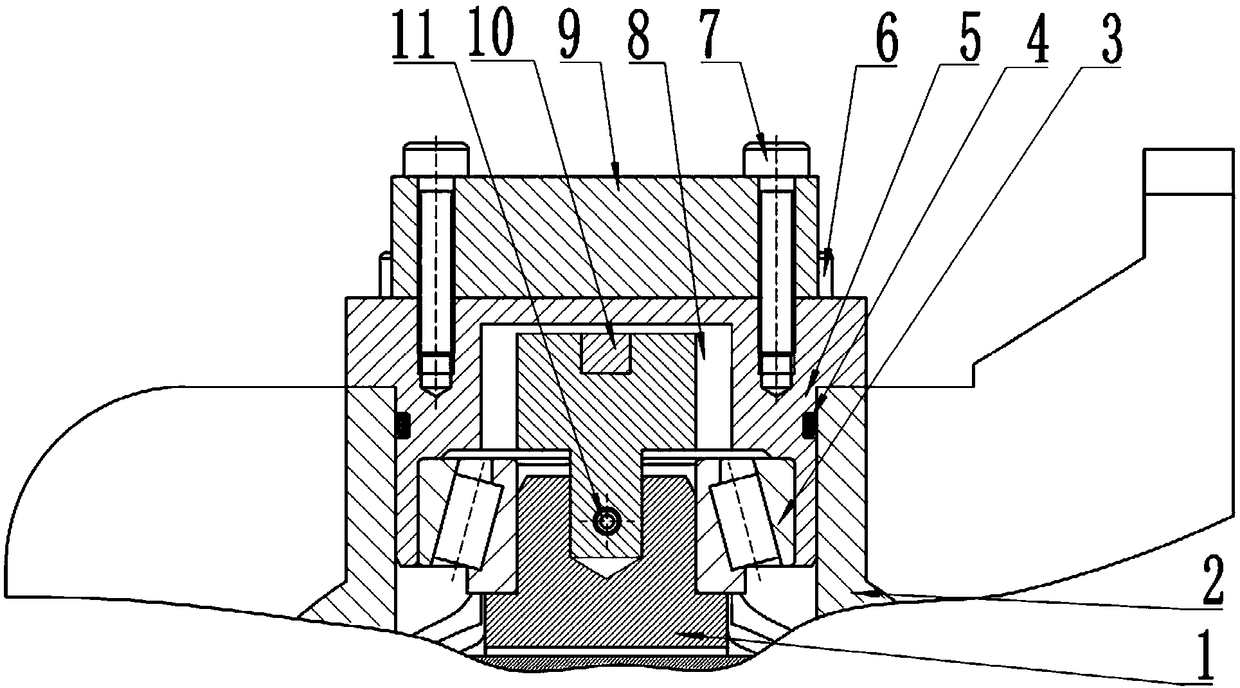

Active-passive hybrid vibration isolator resistant to lateral impact

InactiveCN104992701AGuaranteed to workNo non-linear phenomenaSound producing devicesNoise controlActuator

The invention discloses an active-passive hybrid vibration isolator resistant to lateral impact, and belongs to the technical field of vibration noise control. The active-passive hybrid vibration isolator comprises a passive vibration isolator assembly, an active actuator assembly, and a force transmission assembly. The force transmission assembly is used to connect the passive vibration isolator assembly and the active actuator assembly and transmit force between the passive vibration isolator assembly and the active actuator assembly. The passive vibration isolator assembly supports static load of equipment, attenuates the force of lateral impact through the force transmission assembly, ensures normal work of the active actuator assembly, and has passive vibration isolation performance. The active actuator assembly produces radial output force when electrified, the output force is transmitted to the passive vibration isolator assembly through the force transmission assembly, and the output force is opposite to the exciting force of original radial impact, thus attenuating radial vibration. An active actuator of the vibration isolator is embedded into a passive shock absorber, so that the degree of integration is high. When an application object is subject to lateral impact, the active actuator can still work normally.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

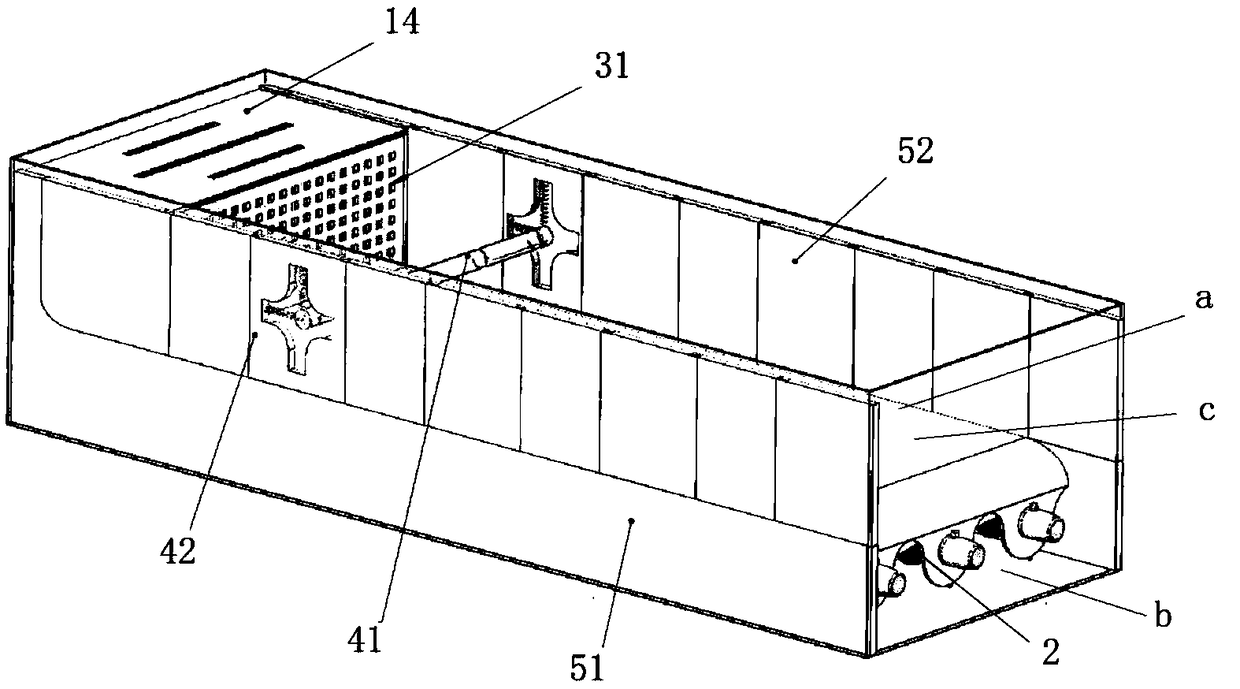

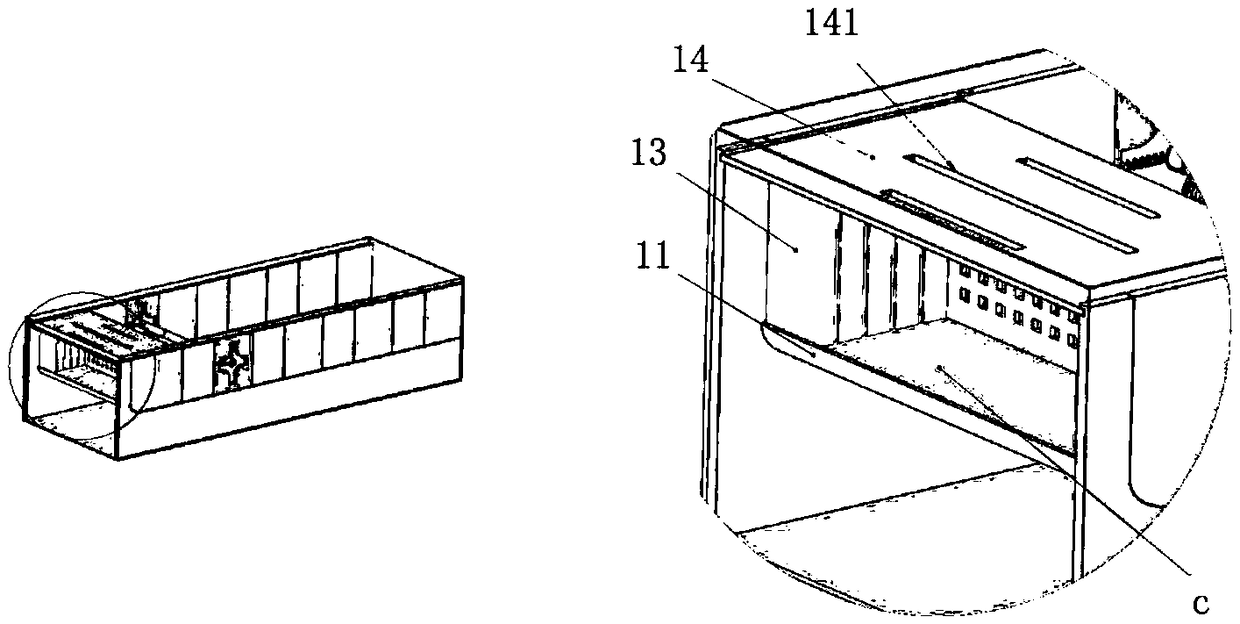

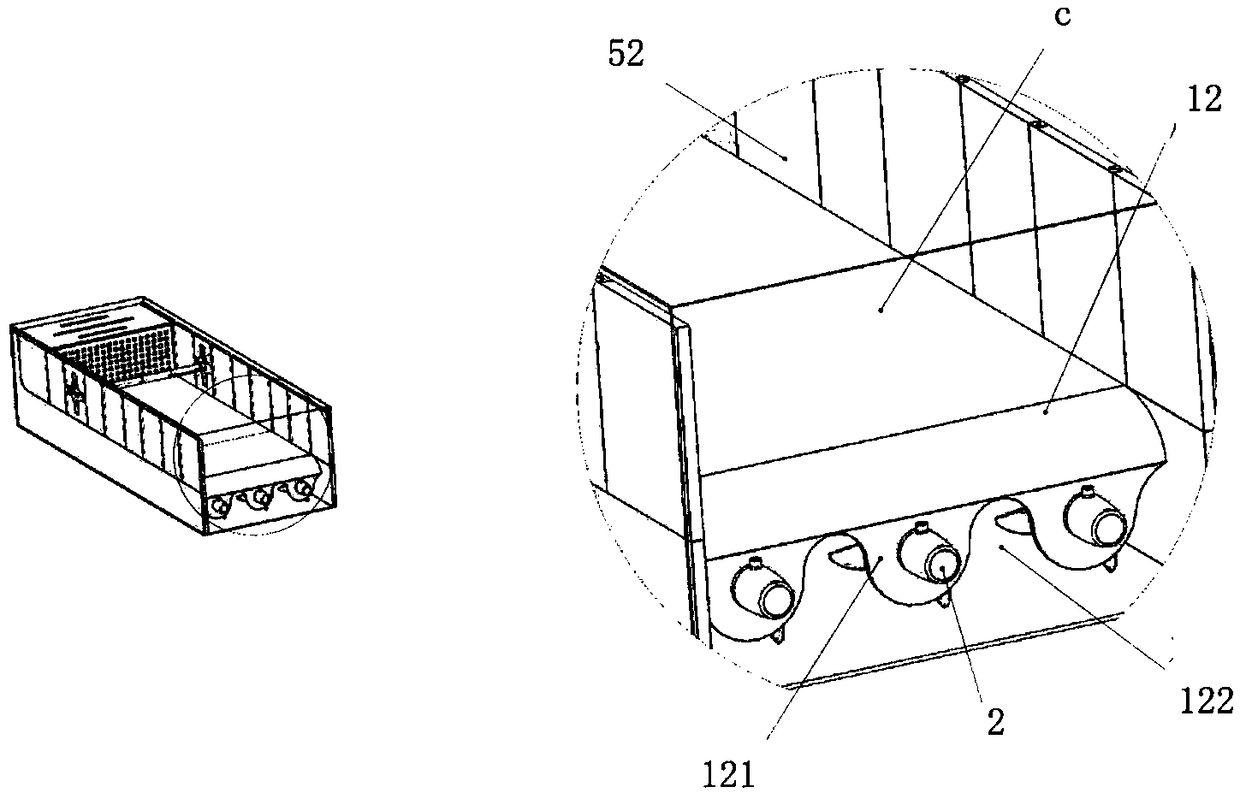

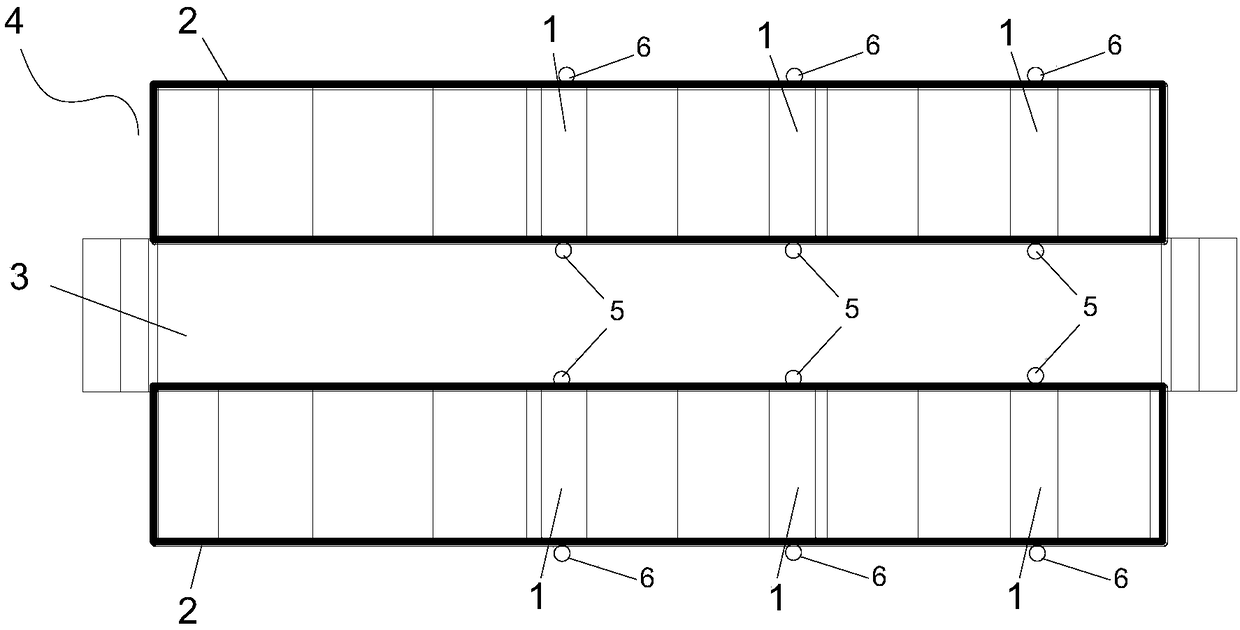

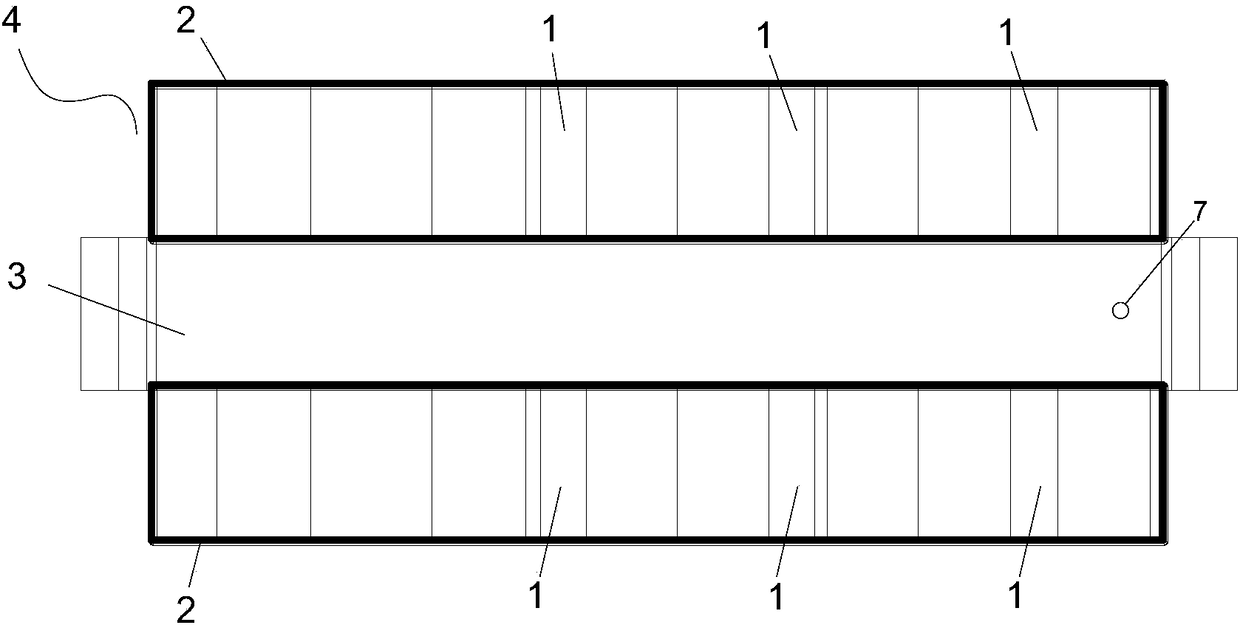

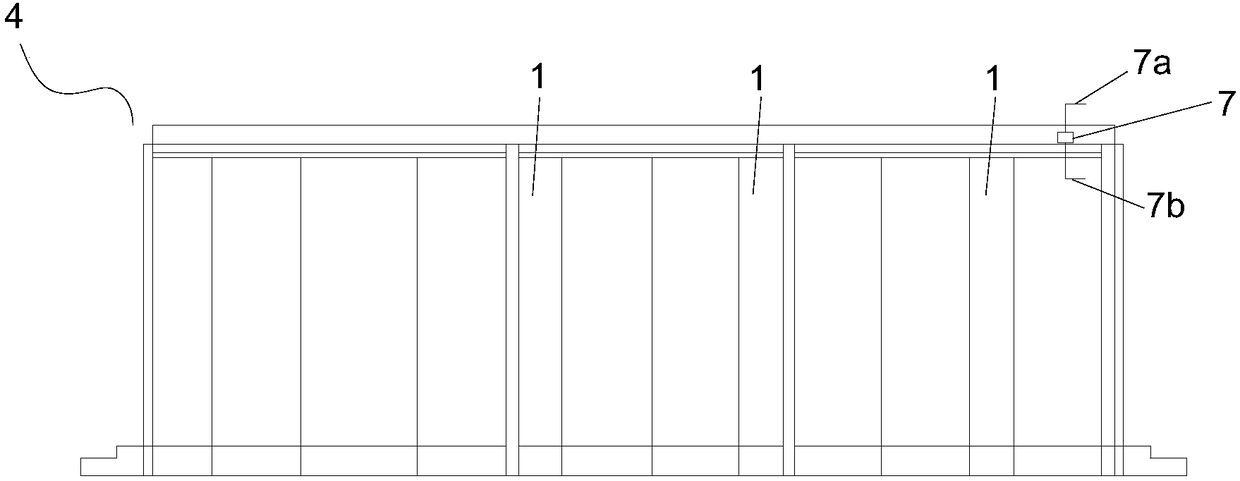

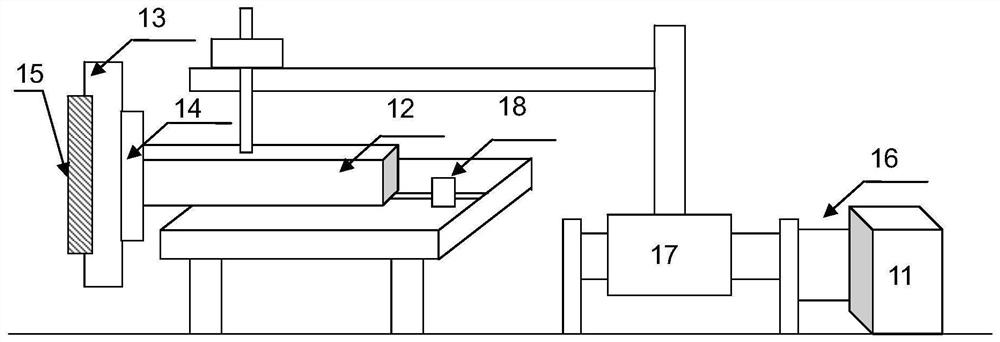

Test water tank for vortex-induced vibration test of suspended spanning pipeline

The invention discloses a test water tank for a vortex-induced vibration test of a suspended spanning pipeline. The test water tank is a cuboid with an opening formed in the upper end surface, and isdivided into a test section and a drainage section by means of a water flow partition plate. The test water tank is provide with a flow direction diversion device, a power adjustable device, a stablewater flow device, a suspended spanning pipeline suspending device, a position adjusting device and a data acquisition device. In the test water tank disclosed by the invention, an upper flow straightener can be moved equidistantly, a flat flow plate is installed in a slot manner, the slot can achieve the anti-collision effect, a thin and long hole is formed to achieve a buffering effect, the disassembly and assembly test is facilitated, the structural installation is reasonable, the suspended spanning pipeline has multiple pipe diameters for the tests of different pipe diameters, lateral andforward springs are convenient for installation and disassembly, a cylindrical suspension plate and a splicing plate are movable and replaceable, tests of water flows in different flow directions canbe conducted, and the test water tank is simple and compact in structure.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Device for measuring swash plate angle and vibration characteristic of high-pressure and high-speed axial plunger pump

PendingCN108663020ASimple structure and low costMinor changesPump testingSubsonic/sonic/ultrasonic wave measurementMechanical wearEngineering

The invention discloses a device for measuring the swash plate angle and the vibration characteristic of a high-pressure and high-speed axial plunger pump. The device comprises a swash plate shaft, aplunger pump shell, a plunger pump sealing cover plate, a magnetic block mounting seat, a noncontact angle sensor, a magnetic block and a plunger pump side end cover. The device has the following advantages: the structure of the axial plunger pump is slightly changed, the processing of the swash plate shaft and the sealing cover plate of the axial plunger pump is only needed, so the processing difficulty is small, and the processing cost is low; the noncontact angle sensor comprises the two following parts: the magnetic block and a sensor body, so the noncontact angle sensor can be easily mounted and maintained; the magnetic block of the noncontact angle sensor is completely sealed, and the magnetic block and the sensor body are separated by the plunger pump sealing cover, so an oil leakage source is reduced; the sensor body is mounted on the outer surface of the sealing cover without arranging a lead wire in the axial plunger pump shell, so the mounting mode is simple; and the swash plate angle and the vibration characteristic of axial plunger pump are measured by sensing the change of a magnetic field direction, so mechanical wearing is avoided.

Owner:ZHEJIANG UNIV

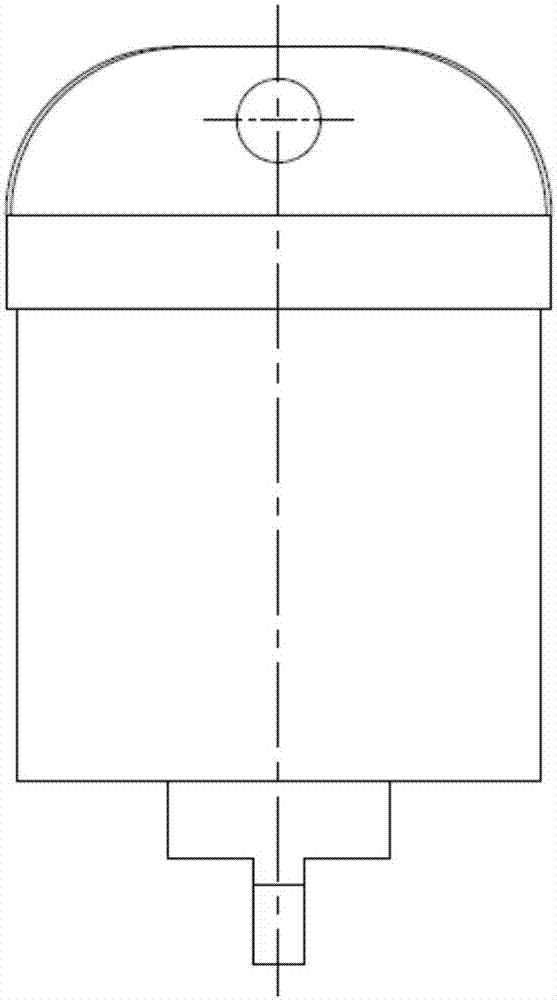

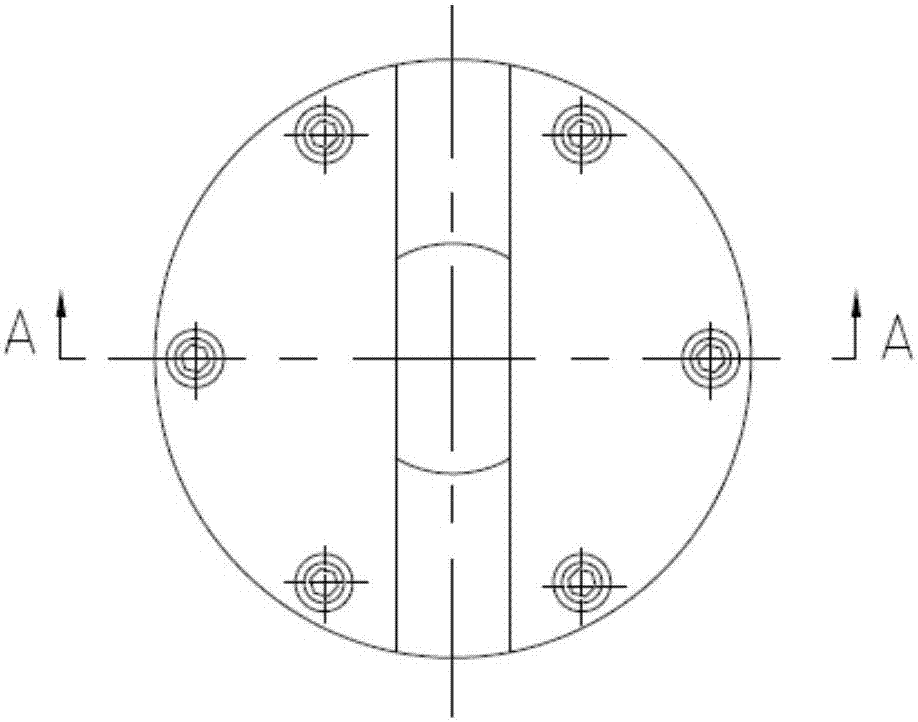

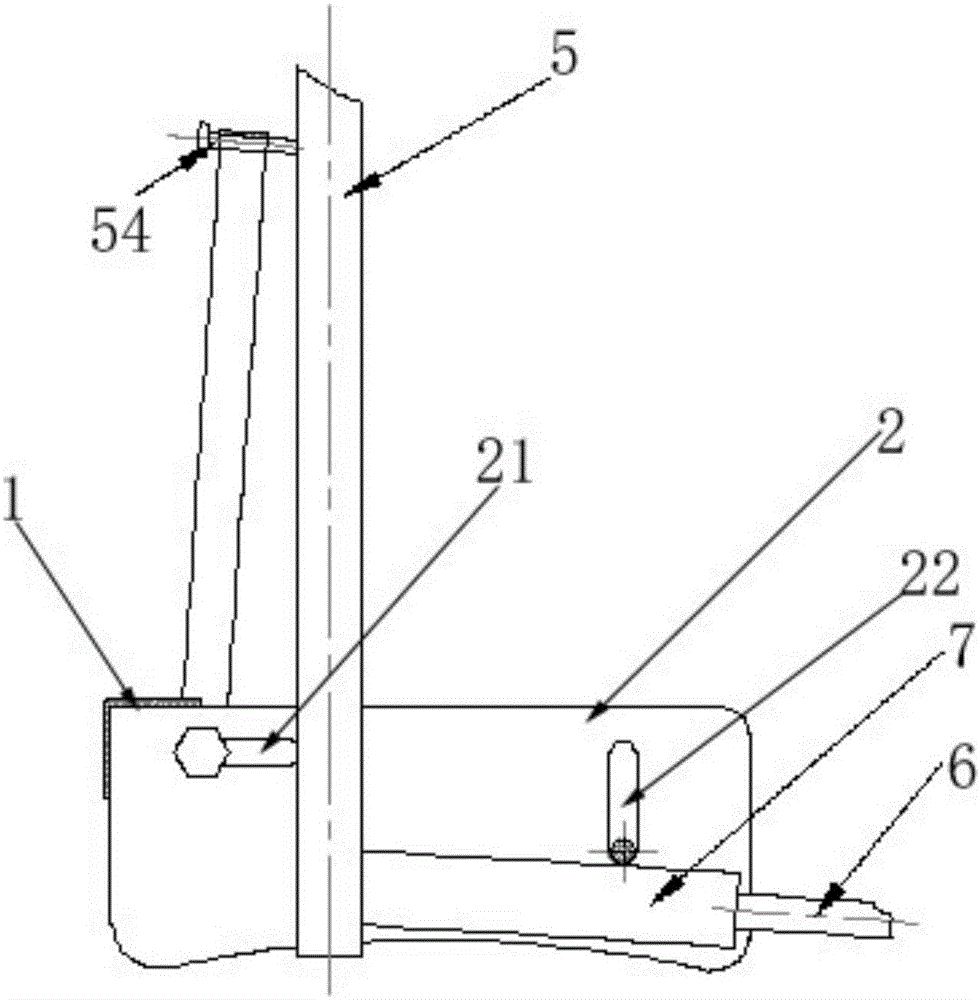

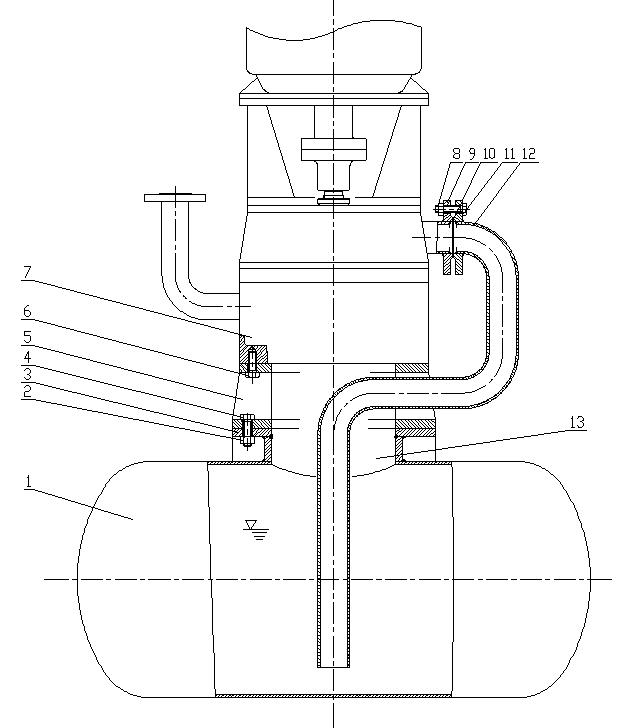

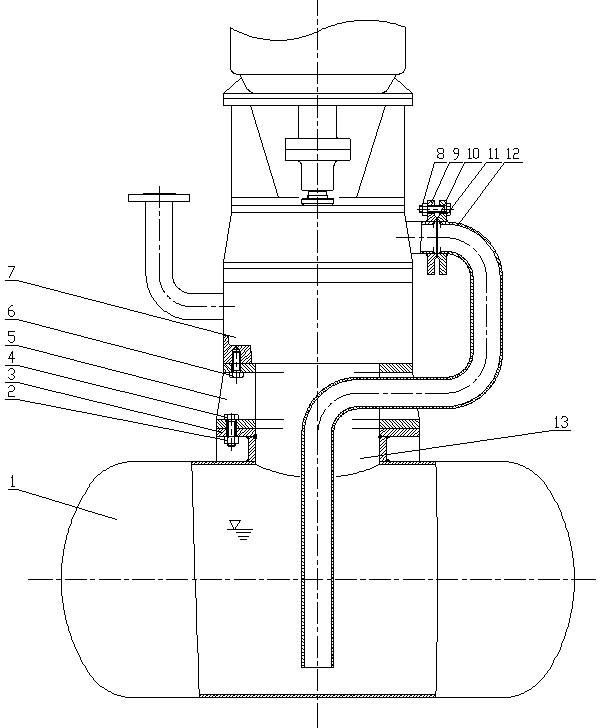

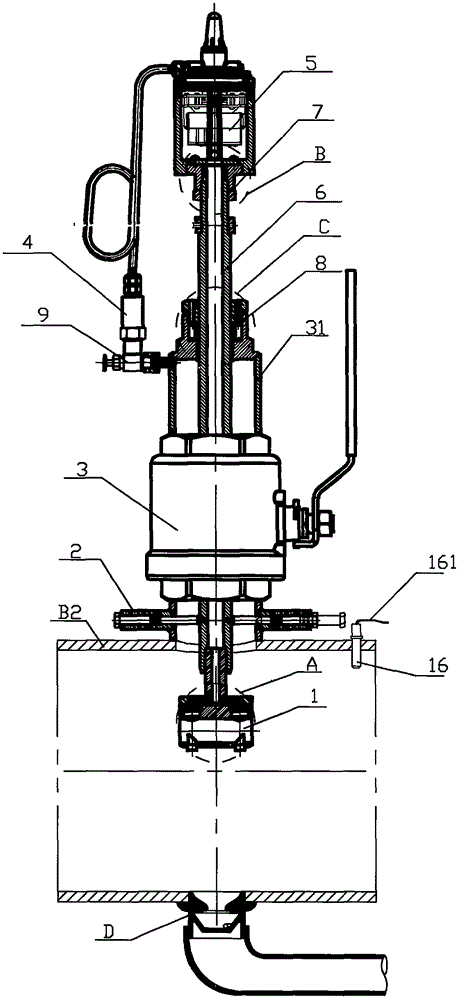

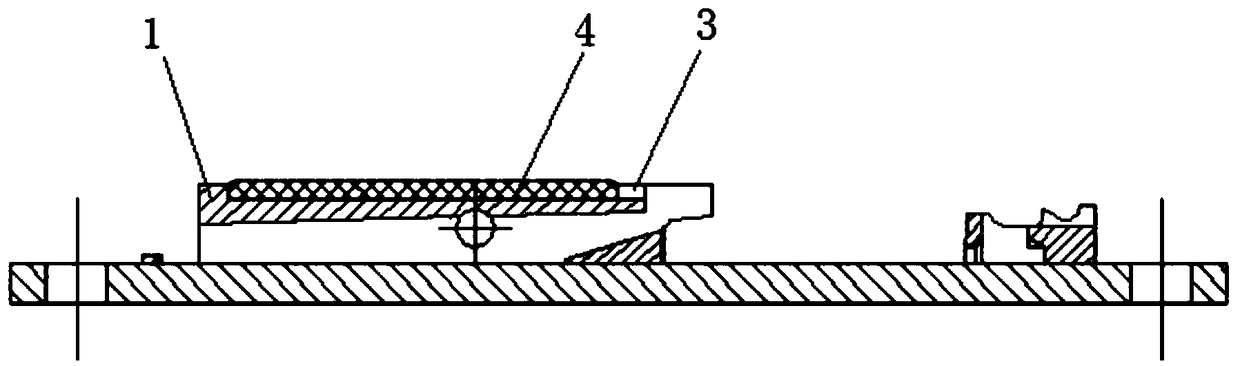

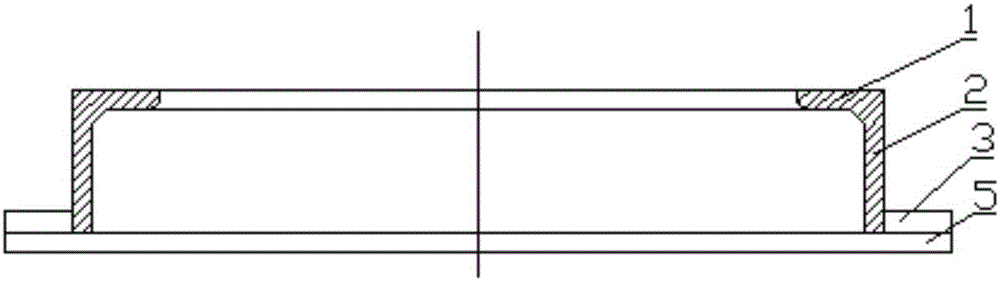

Installation structure of vertical self-priming pump on chemical tank

InactiveCN102536873ALow costSimple and reliable installationPump componentsPumpsEngineeringChemical tank

The invention relates to an installation structure of a vertical self-priming pump on a chemical tank. The installation structure is characterized in that a base is installed on the vertical self-priming pump through a bolt B, an inlet special-shaped pipe penetrates through the base and is fixed on the inlet flange of the vertical self-priming pump through a bolt C and a nut B, an inlet rubber gasket is adopted for sealing between the inlet special-shaped pipe and the inlet flange of the vertical self-priming pump, the vertical self-priming pump is lifted up and installed on a tank body flange through the base, the base and the tank body flange are fixedly connected through a bolt A and a nut A, a tank body flange opening is arranged on the tank body flange and one end of the inlet special-shaped pipe stretches into liquid in a tank body. The installation structure of the vertical self-priming pump on the chemical tank has the advantages that: 1) the cost is saved, the tank body and the tank body flange are not required to be modified at all, the vertical self-priming pump is not required to be modified at all, and two simple parts, i.e. the base and the inlet special-shaped pipe are only required to be added; and 2) the installation method is simple and reliable, the entire installation can be completed as long as the base and the tank body flange are connected through the bolt and the nut, and the entire process is simple and easy to operate.

Owner:ZHENJIANG ZHENGHAN PUMP

Cooling room and cooler unit air volume control method of cooling room

PendingCN109028444ASynchronous adjustment of air volumeImprove operation and maintenance management efficiencyMechanical apparatusSpace heating and ventilation safety systemsAir volumeAir velocity

The invention discloses a cooling room and a cooler unit air volume control method of the cooling room. The cooling room comprises a cooling room body, an air velocity sensor and a cooler unit. A through hole is formed in the cooling room body. The cooling room body is internally provided with an accommodating space. The accommodating space is internally provided with a cooling channel and a storing space. The cooling channel communicates with the outside of the cooling room body by the through hole. The air velocity sensor is arranged at the through hole. The air outlet of the cooler unit communicates with the cooling channel. The cooler unit is used for supplying air to the cooling channel based on detection data of the air velocity sensor, and therefore the cooling channel can cool thestoring space. The technical problems of the poor synchronism between cooler unit air output and actual demand and poor draught fan rotating speed controlling stability are solved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

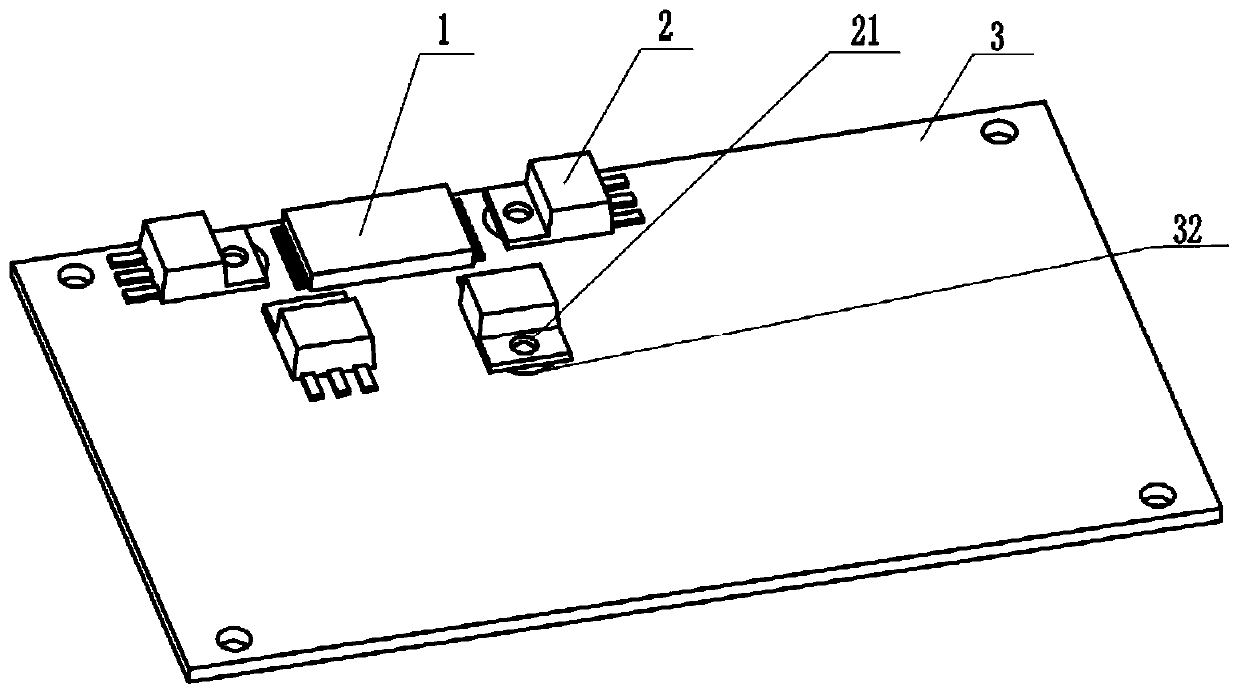

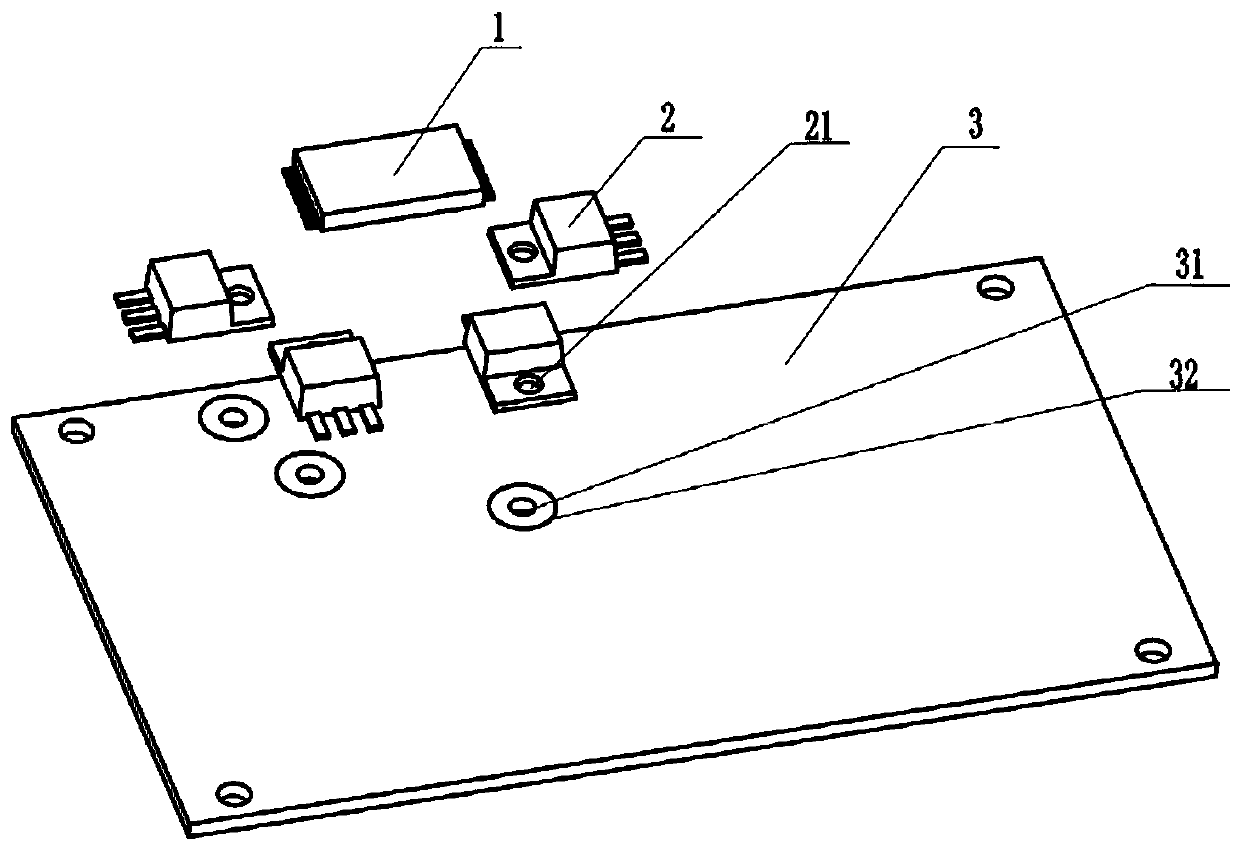

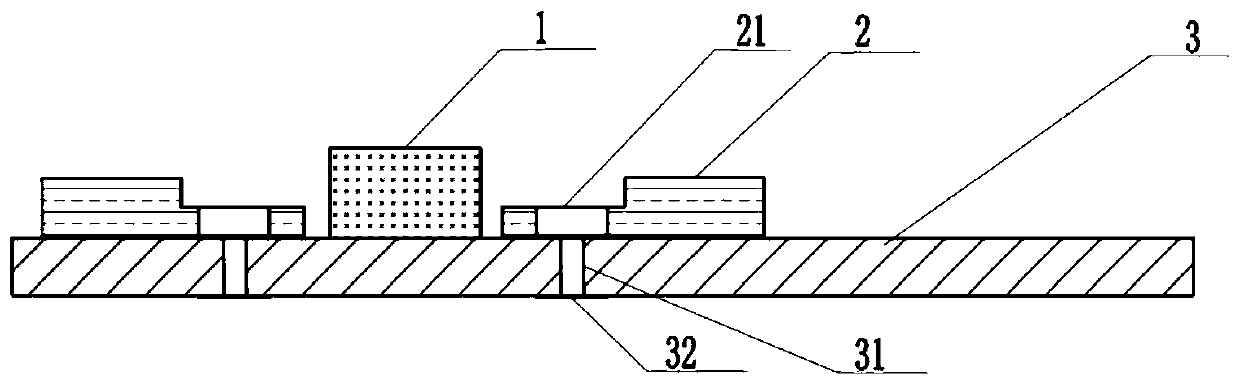

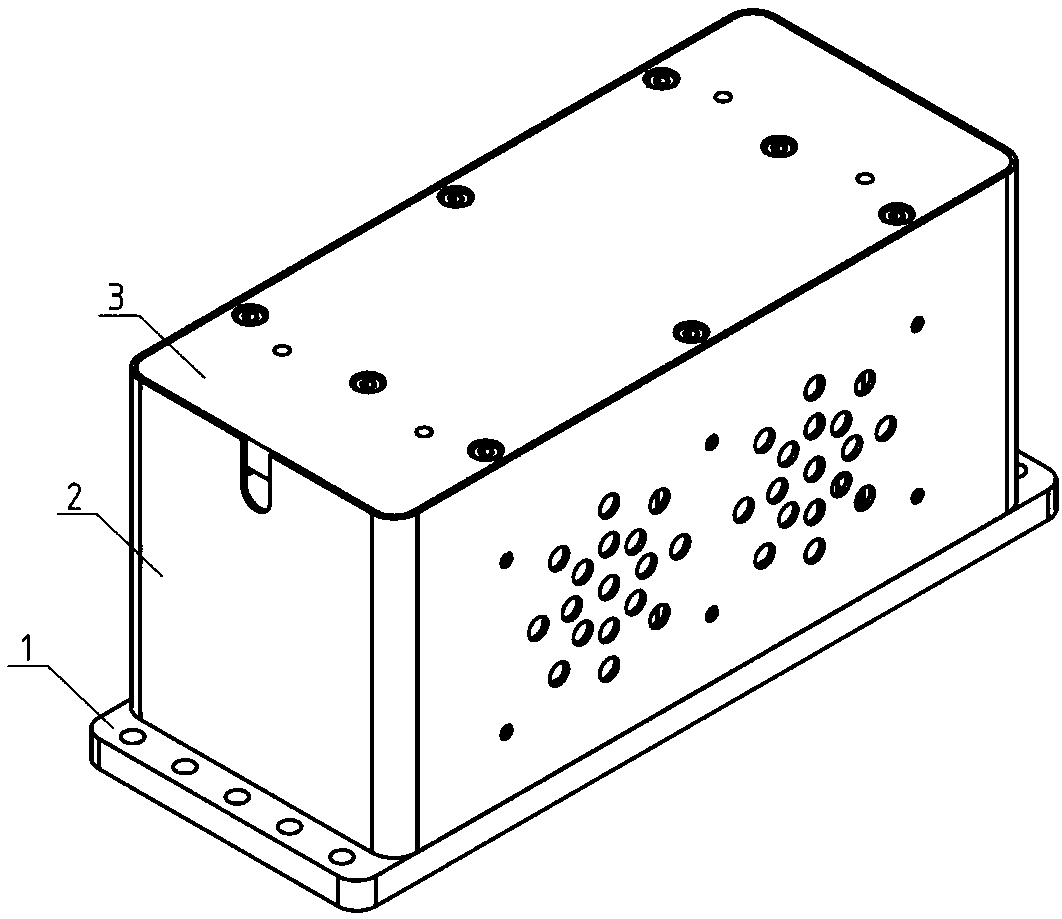

High-efficiency and low-cost PCB heat dissipation device

ActiveCN110868796AHigh Efficiency Dual Heat DissipationSave materialPrinted circuit aspectsPrinted circuit non-printed electric components associationHemt circuitsHeat sink

The invention relates to the field of PCB circuits, in particular to a high-efficiency and low-cost PCB heat dissipation device. The high-efficiency and low-cost PCB heat dissipation device comprisesa PCB, a chip and a heating device are arranged on the PCB, a through hole is formed in the PCB, an installation hole is formed in the heating device, and the installation hole and the through hole inthe PCB are concentrically arranged. The invention relates to the high-efficiency and low-cost PCB heat dissipation device, in which the thermal resistance in the heat conduction process is reduced,short-distance efficient heat conduction and radiation to a shell in a small space is realized, the fixing mode of heat dissipation fins is simplified, the mounting difficulty is reduced and the material cost is saved.

Owner:HANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

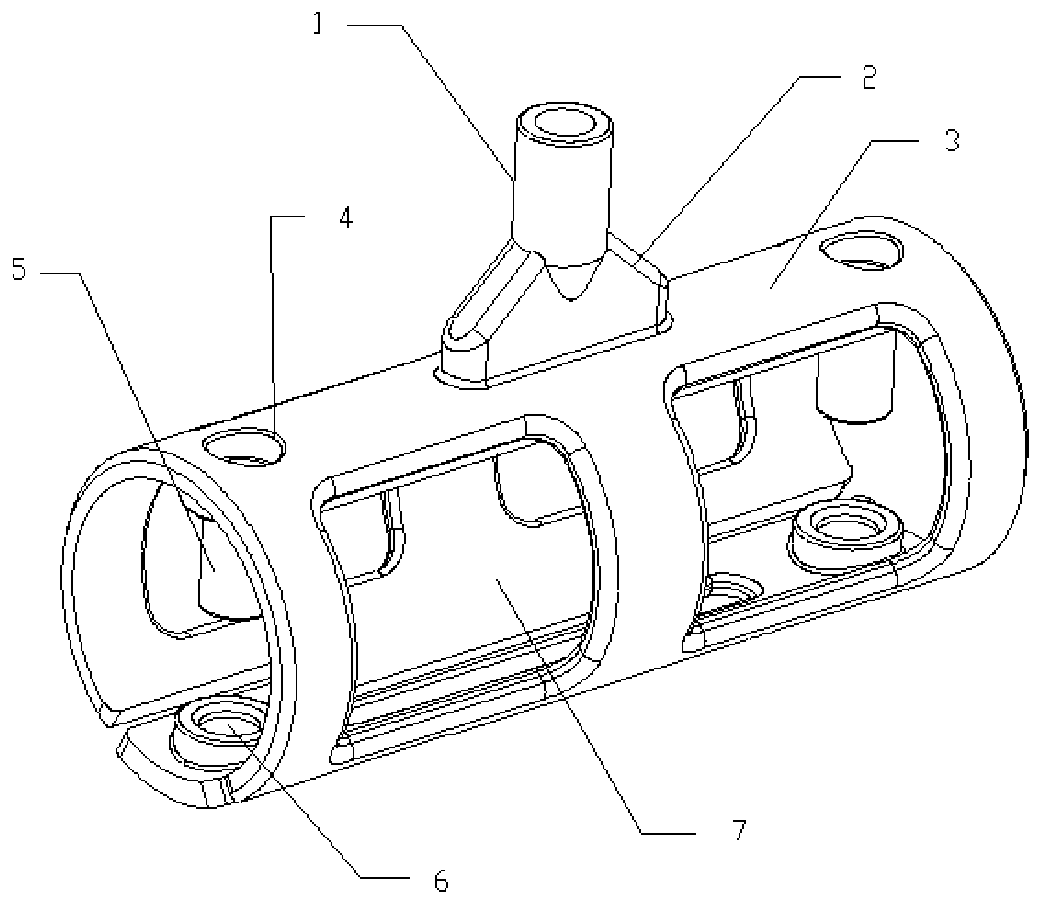

Throttler for air floatation part and air floatation piston comprising throttler

PendingCN113958561AImprove reliabilityAchieve air flotationGas cushion bearingsFluid-pressure actuatorsInterference fitRough surface

The invention provides a throttler for an air floatation part and an air floatation piston comprising the throttler. The air floatation part is provided with a mounting cavity for mounting the throttler and an air outlet hole which communicates with the mounting cavity; the local area or the whole area of the outer side face of the throttler is a rough surface, the throttler is fixedly connected to the air outlet hole in the mounting cavity in an interference fit connection mode, part of the rough surface of the throttler faces the air outlet hole, after air enter into the mounting cavity, and the air makes contact with the rough surface and flows into the air outlet hole through the rough surface to achieve gas throttling. Compared with single small hole throttling, the throttler has the advantages that the risk of dirt dust particle blockage can be reduced, the throttling reliability is improved, throttling is achieved through the rough surface, machining is easy, large-batch production and installation are convenient, and the cost is low.

Owner:LIHAN CRYOGENICS

Insertion type ultrasonic flowmeter

InactiveCN105737920ASimple and reliable installationEasy access and maintenanceVolume/mass flow measurementSpray nozzlesNull pointBall valve

The invention provides an insertion type ultrasonic flowmeter.The insertion type ultrasonic flowmeter comprises a connecting rod; the lower end of the connecting rod is fixed to a flow reflection mechanism through a locating screw, the outer wall of the middle of the connecting rod is connected with a ball valve in a sleeved mode, and the upper end of the connecting rod is fixed to a meter head assembly through a meter head connecting assembly; a pressure sensor assembly is arranged between the ball valve and the meter head assembly and connected with the meter head assembly and a connecting pipe of the ball valve respectively; the flow reflection mechanism can be arranged in a pipeline and comprises a fixed base like a hollow pipe, the outer wall of the fixed base is fixed to the lower end of the connecting rod, two ultrasonic sensors are fixed to the upper end of the inner wall of the fixed base, and two ultrasonic reflectors are fixed to the lower end of the inner wall of the fixed base; the two ultrasonic sensors and the two ultrasonic reflectors are located in the same right-angle quadrangle, and opposite end faces of the two ultrasonic reflectors are each provided with a bevel used for reflecting ultrasonic waves.Through the insertion type ultrasonic flowmeter, installation is simple and reliable, there is no need to conduct null point debugging or flow calibration on site, and overhaul and maintenance in a later period are both convenient.

Owner:贺成

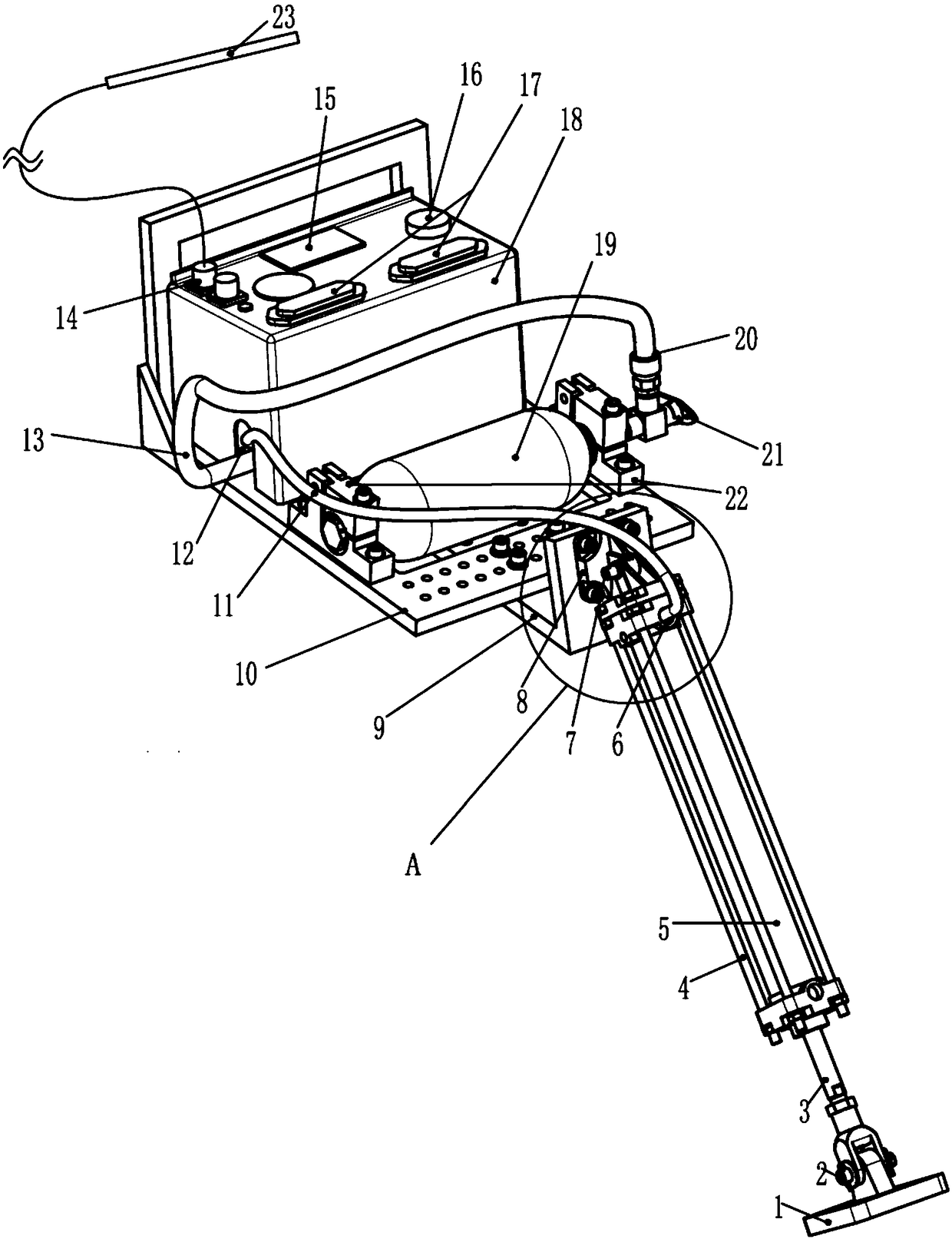

Vehicle-mounted brake device for automobile rear impact test

PendingCN108956152ASimple and reliable installationEasy to brakeVehicle shock testingLeg typeAnkle motion

The invention discloses a vehicle-mounted brake device for an automobile rear impact test, which mainly comprises an electric control device, a pneumatic device and a mechanical connection device. Theelectric control device comprises a controller; the controller is electrically connected with a valve control module, a test trigger interface, a reset button, a trigger switch and a delay module; the test trigger interface is externally connected to the trigger switch; and the trigger switch is attached to the most protruding part of the rear impact surface of an impacted vehicle. The pneumaticdevice comprises a gas cylinder, a pipeline and a leg type device, the gas cylinder is connected with the leg type device through the pipeline, the valve control module is arranged on the pipeline, and the leg type device is a cylinder and piston rod assembly; the mechanical connection device is used to connect the leg type device to a seat and simulate knee and ankle motions. The vehicle-mountedbrake device has the advantages of simple structure, convenient installation, stable and reliable braking effect, and installation and use are not limited by the vehicle type.

Owner:长春汽车检测中心有限责任公司

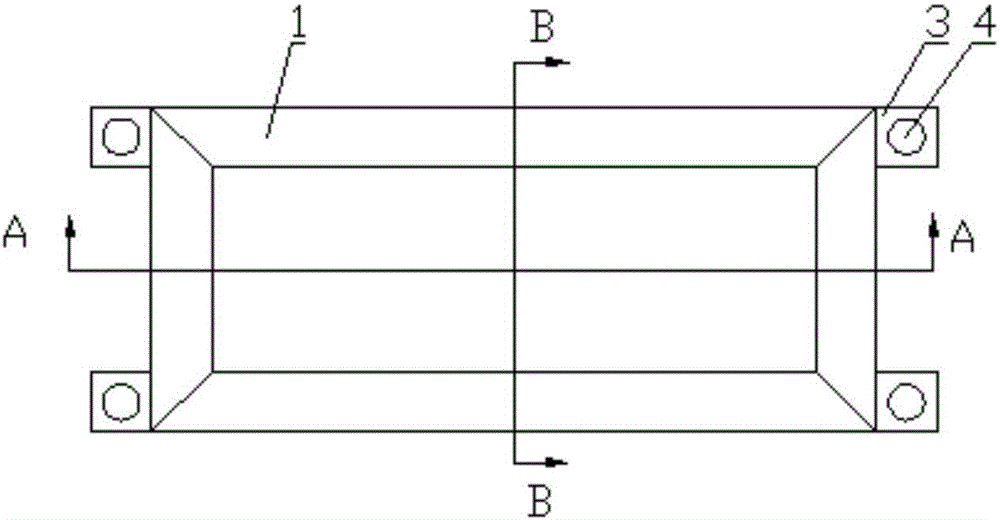

Self-lubricating friction-reducing sliding bed plate

PendingCN109183526ASimple and reliable installationSimple structureRail switchesWear resistantAdhesive

The invention provides a self-lubricating friction-reducing sliding bed plate, being characterized in that a square groove (2) is arranged on the upper end face of a sliding bed table (1); a wear-resisting self-lubricating plate (4) is embedded into the square groove (2); front, rear, left, right and lower directions of the wear-resisting self-lubricating plate (4) are positioned by the square groove (2), and the upper surface of the wear-resisting self-lubricating plate (4) is protruded from the upper end face of the sliding bed table (1); the square groove (2) is a rectangular groove, and one side of the rectangular groove is provided with a notch (3); the wear-resistant self-lubricating plate (4) is a rectangular structure formed in one step; and the wear-resistant self-lubricating plate (4) and the square groove (2) are bonded together by an adhesive, so that the wear-resisting self-lubricating plate (4) and the sliding bed table become an integral whole. The invention simplifies the structure of the sliding bed table, has lower manufacturing cost and high production efficiency; the wear-resistant self-lubricating plate is made of modified polytetrafluoroethylene, which can effectively reduce the surface friction coefficient of sliding table, and its wear resistance and plastic creep resistance can meet the requirements of the tip rail.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

Online detection device for shield tunneling machine cutter

PendingCN113607212ASimple and reliable installationNo complicated flush-mounting process requiredMeasurement devicesControl systemLaser sensor

The invention provides an online detection device for a shield tunneling machine cutter, which relates to the technical field of shield tunneling machines. The device comprises a blind hole, a reflector, a laser sensor, a transparent plug, a magnetic object to be detected, a magnetic sensor, an acceleration sensor and a signal acquisition and control system, wherein openings of the blind holes are formed in an inner wall of a cutter hub and extend into a cutter ring; the reflector is arranged at the bottom of the blind hole; the laser sensor is arranged on the cutter shaft sleeve, emits a laser signal into the blind hole and receives a reflected laser signal; the transparent plug is arranged at one end of the blind hole close to the opening; the magnetic object to be detected is arranged on an inner wall of the cutter hub; the magnetic sensor is arranged on the cutter shaft sleeve and is used for detecting the magnetic object to be detected; the acceleration sensor is arranged on a shaft sleeve of the cutter shaft and used for monitoring a vibration state of the cutter in the operation process. The device is advantaged in that technical problems that in the prior art, a traditional detection method is complex in process, low in reliability and safety, difficult to deal with complex geology and prone to causing damage to a system are solved.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

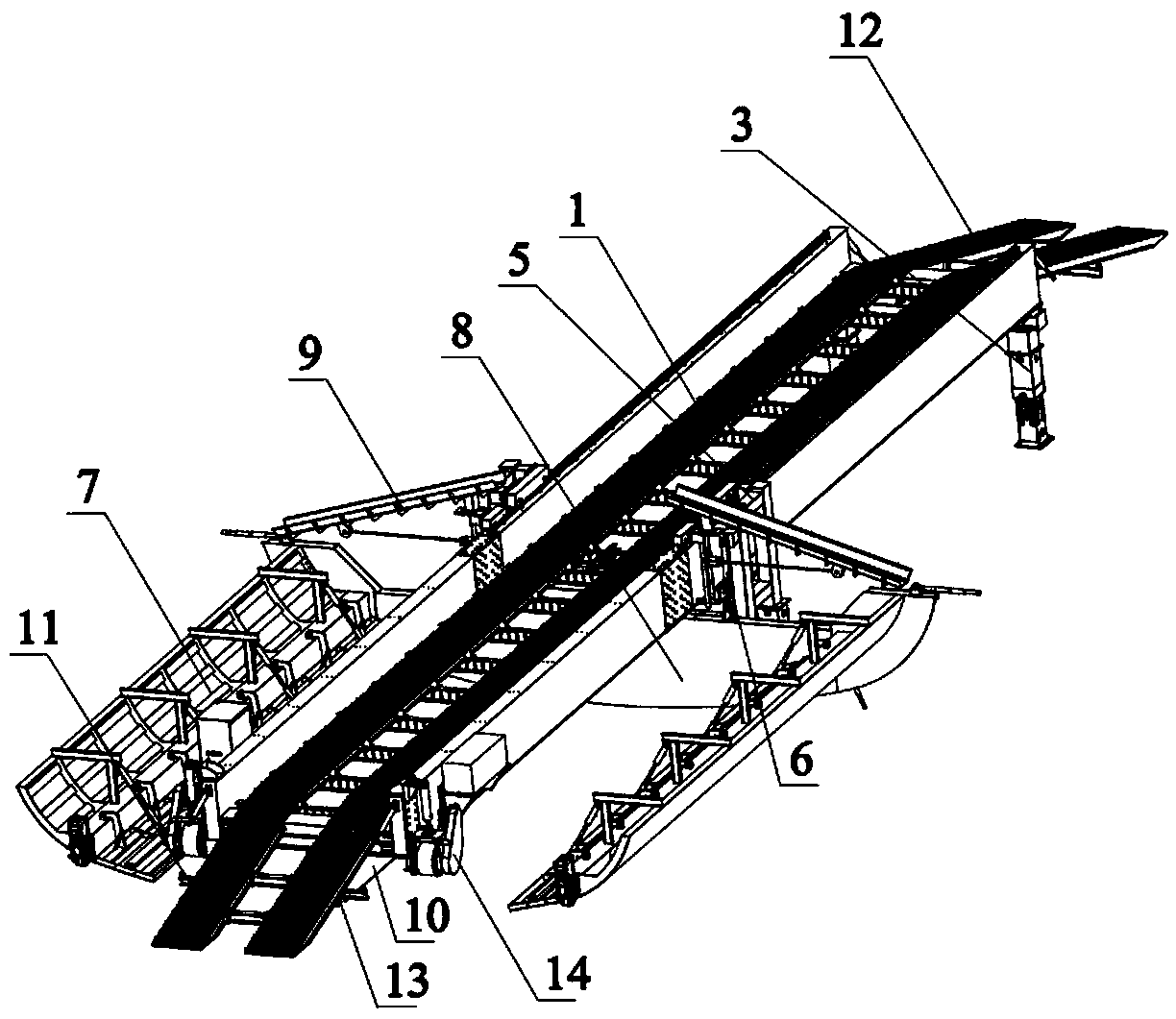

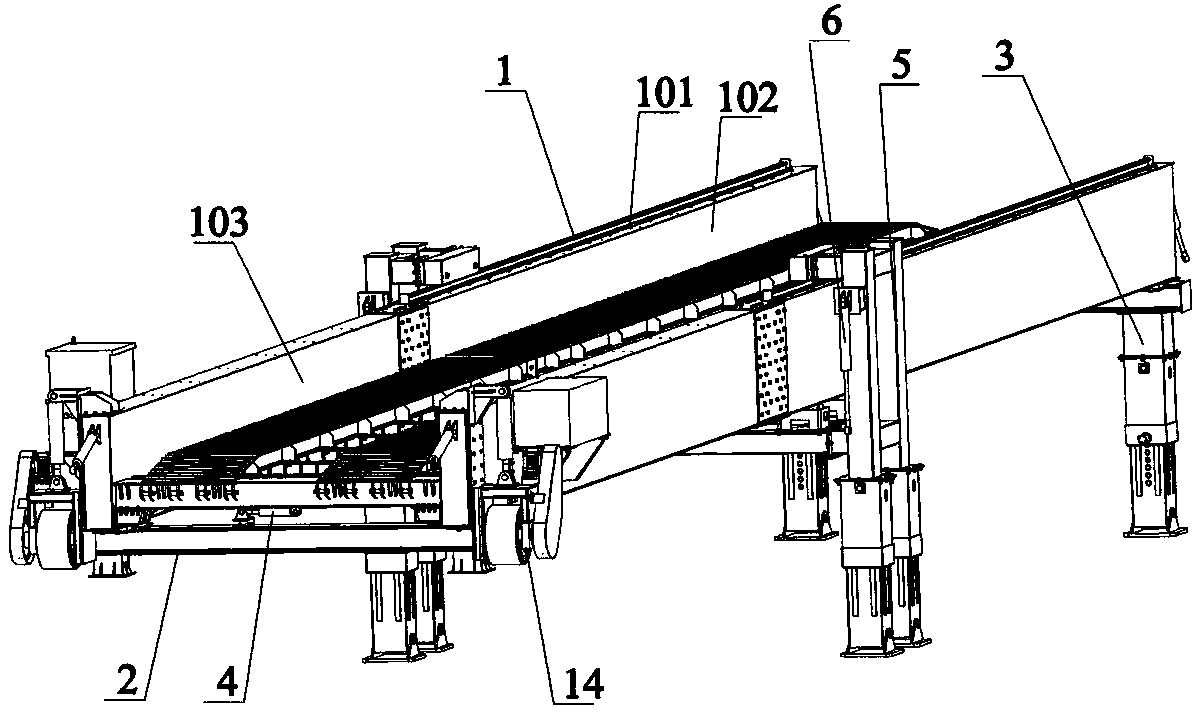

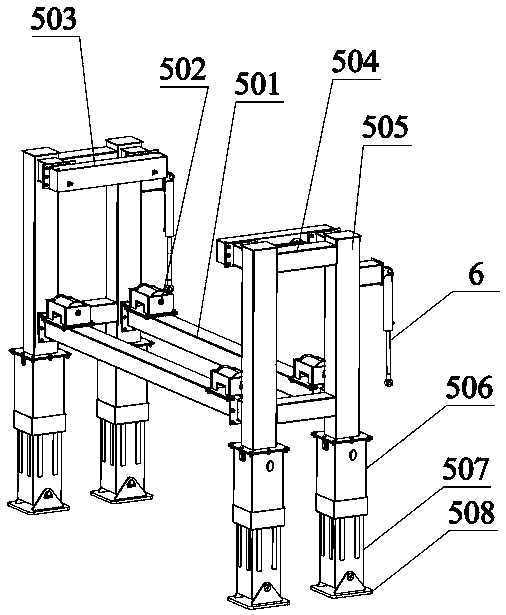

Self-propelled movable inverted arch trestle

InactiveCN111550269AReduce labor intensityReduce labor costsUnderground chambersTravelling bridgesHydraulic ramHydraulic pressure

The invention provides a self-propelled movable inverted arch trestle. According to the self-propelled movable inverted arch trestle, the left-right position of an inverted arch formwork system and abridge main body can be adjusted through a transverse movement hydraulic oil cylinder, the front-rear position of the inverted arch formwork system can be adjusted through a trestle travelling mechanism, and the vertical height of the inverted arch formwork system can be adjusted through a lifting mechanism on the inverted arch formwork system, so that the positioning of the inverted arch formworksystem is more accurate and faster, and construction requirements of high standards can be met. In addition, the inverted arch formwork system can realize the inverted arch operation construction ofa whole tunnel with the same section after being installed at a time, formwork assembly and disassembly are omitted, movement and positioning are mechanically controlled in a full-automatic mode, thelabor intensity of workers is greatly reduced, the labor cost is saved, and the construction efficiency and the construction quality are improved.

Owner:李军

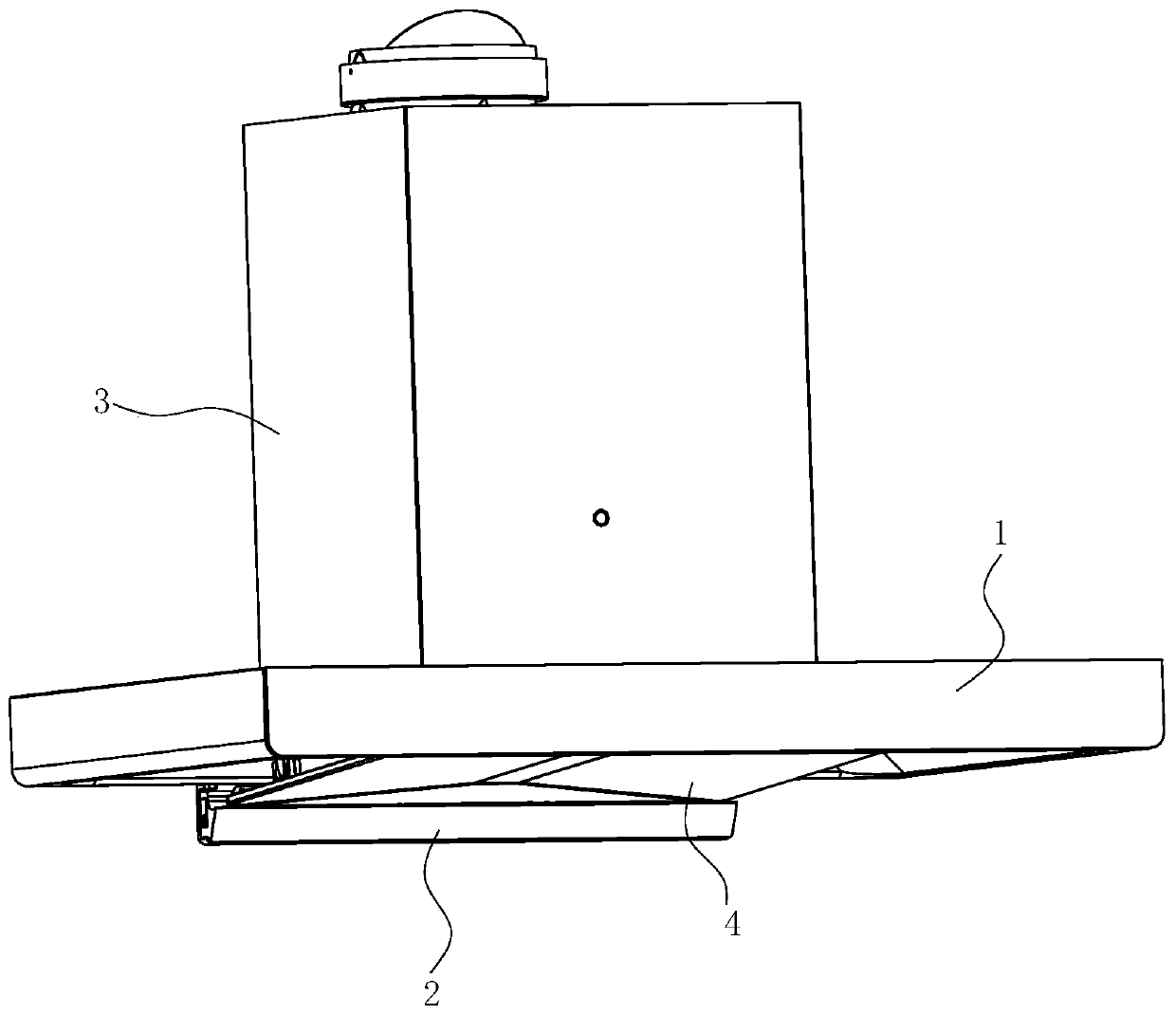

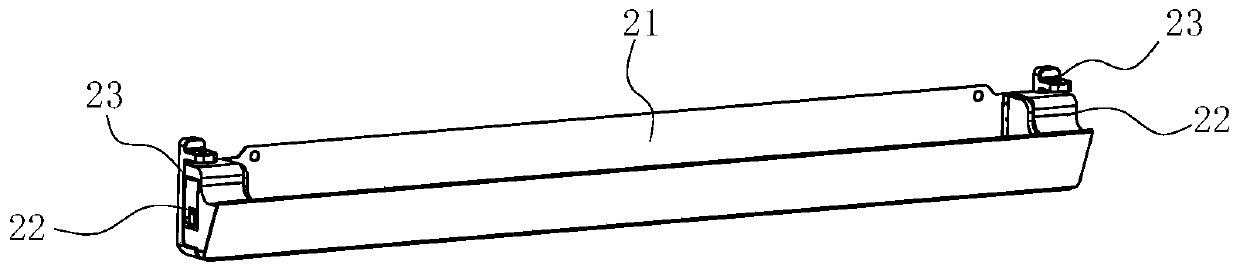

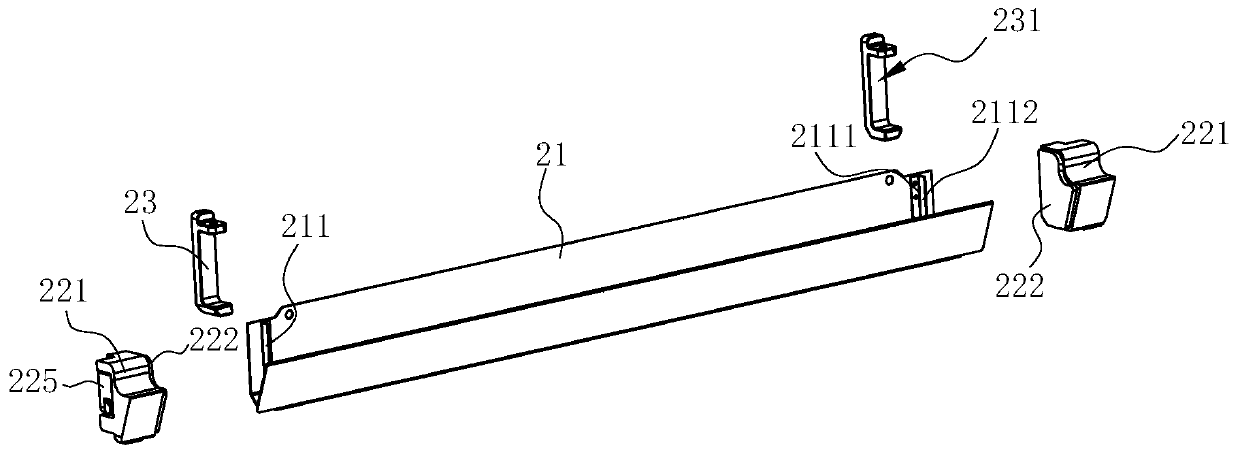

Oil collecting device and range hood applying same

ActiveCN111156553AInhibit sheddingAvoid misuseDomestic stoves or rangesCooking fumes removalMechanical engineeringPetroleum engineering

The invention discloses an oil collecting device. The oil collecting device comprises an oil cup body with an opening in the top end, and is characterized in that the two ends of the oil cup body in the length direction are open; and the oil collecting device further comprises plug mechanisms detachably arranged at the openings in the two ends of the oil cup body as well as hooks used for being connected with an external installation foundation, wherein the two ends of the oil cup body are sealed through the plug mechanisms, and the plug mechanisms are clamped into the hooks. The invention further discloses a range hood applying the oil collecting device. Compared with the prior art, the oil collecting device and range hood applying the same has the advantages that the two ends of the oilcup body are blocked through the detachable plug mechanisms, the plug mechanisms cooperate with the hooks so that the oil collecting device can be conveniently installed, the installation mode is simple and reliable, and installation failure caused by insertion pieces can be avoided.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

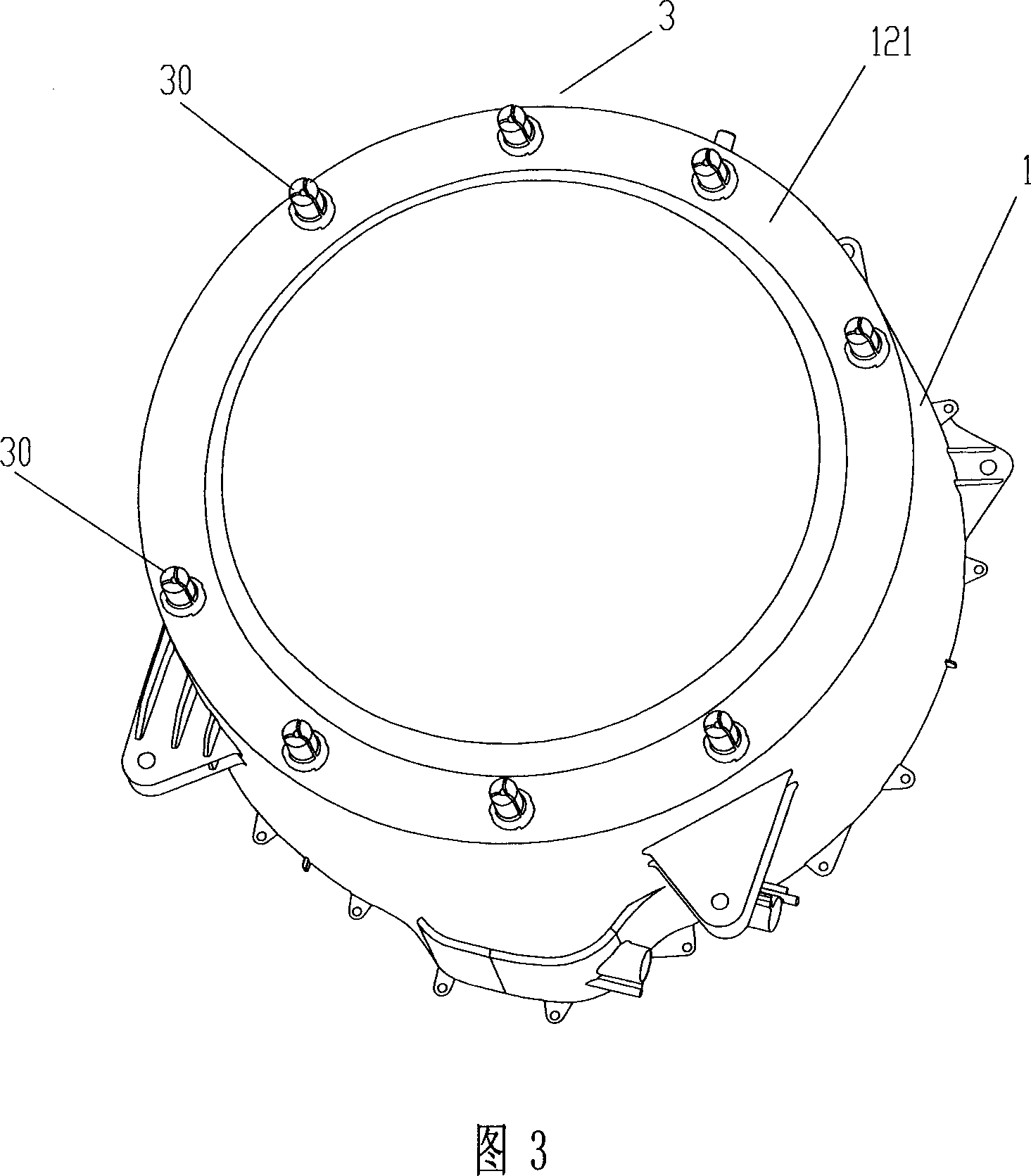

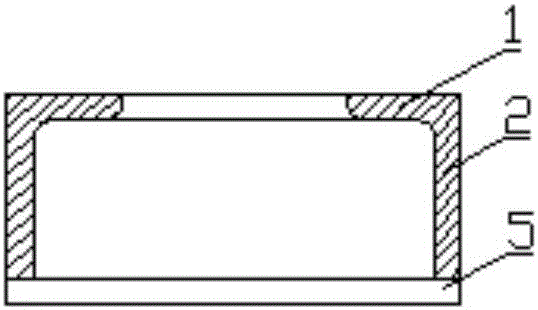

Fixed device of permanent magnet and permanent-magnet motor

InactiveCN106208462APrevent tamperingSimple structureMagnetic circuit rotating partsMagnetEngineering

The invention discloses a fixed device of a permanent magnet. The fixed device comprises a cover body, wherein the cover body covers the permanent magnet to make the permanent magnet fixed on a rotor and comprises a rectangular-ambulatory-plane top plate and side plates, the rectangular-ambulatory-plane top plate is fixedly connected, and the side plates encircle the top plate; when the fixed device is used, the cover body covers the permanent magnet, the permanent magnet can be pressed on the rotor by the rectangular-ambulatory-plane top plate and is prevented from being disconnected with the rotor, the permanent magnet can be circumferentially fixed by the side plates and is prevented from moving, a rectangular-ambulatory-plane gap can be formed in the periphery of the top of the permanent magnet and is matched with the rectangular-ambulatory-plane top plate, a top surface of the permanent magnet can be flush with an external plate surface of the top plate, an air gap is reduced, the external diameter size of the rotor is reduced, the magnetic hysteresis loss is reduced, and the magnetic field utilization ratio is improved. Therefore, the fixed device of the permanent magnet, provided by the invention, is simple in structure, and the permanent magnet can be simple and reliable to install and fix. The invention also discloses a permanent magnet motor comprising the abovementioned fixed device of the permanent magnet.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

Refrigerator handle structure

InactiveCN103850524AEasy to assembleSoft touchWing handlesDomestic cooling apparatusEngineeringRefrigerated temperature

The invention relates to the technical field of a refrigerator in an electric appliance, in particular to a refrigerator handle structure. The refrigerator handle structure comprises a handle main body, wherein the handle main body is provided with a first groove and a second groove, a piece of handle glass is fixed in the first groove, and a handle gasket is fixedly arranged in the second groove. A layer of gasket which is made of TPE is added onto the part, which makes contact with the hand of the user, of the aluminum-alloy handle main body when the refrigerator door is opened, so that the refrigerator handle is soft and warm to touch when the refrigerator door is opened; moreover, a layer of tempered glass is additionally attached on the surface of the handle, the refrigerator handle can be beautified by changing the pattern of the tempered glass and utilizing the attractive patterns of the tempered glass, and the appearance of the handle also can be changed by changing the glass pattern.

Owner:HISENSE RONSHEN GUANGDONG REFRIGERATOR

High-temperature ultra-high-speed friction-wear testing machine for sealing coating

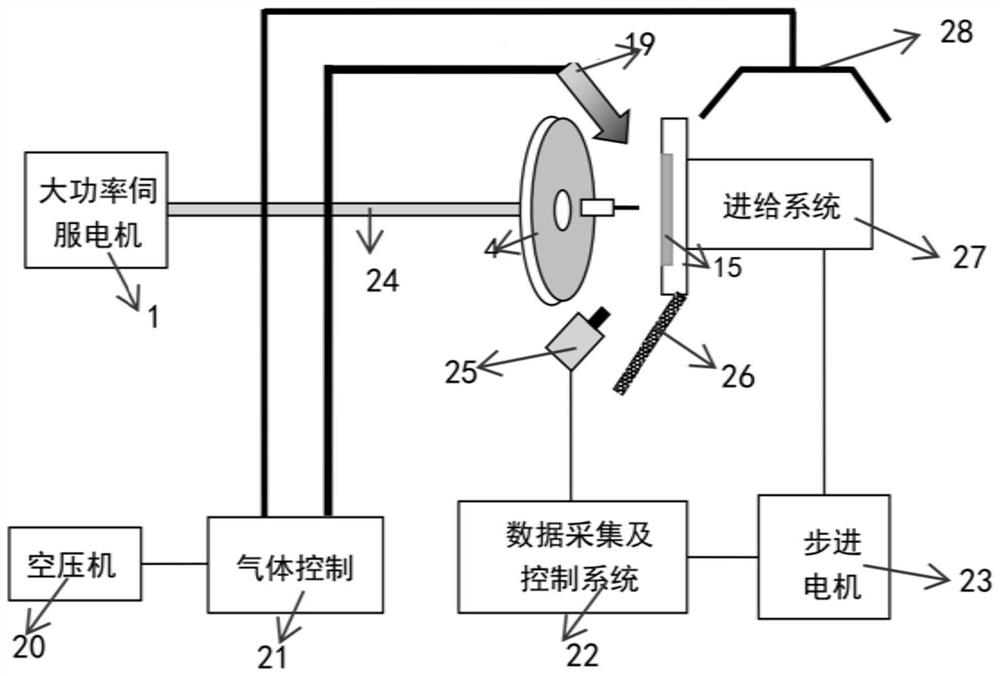

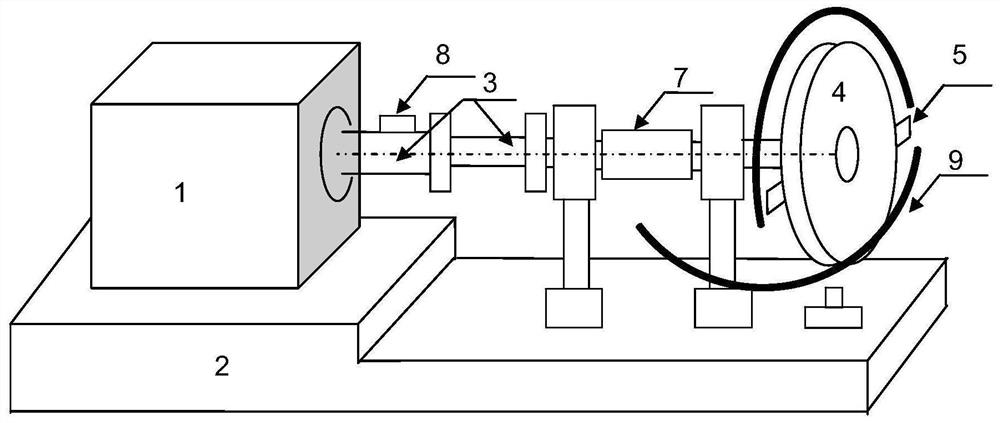

PendingCN113945476AReasonable layoutCompact structureInvestigating abrasion/wear resistanceData acquisitionControl cell

The invention provides a high-temperature ultra-high-speed friction-wear testing machine for sealing coating. A motor and transmission system comprises a servo motor, a transmission system and a wheel disc, one end of the transmission system is connected with the servo motor, and the other end of the transmission system is connected with the wheel disc; the edge of the wheel disc is provided with simulation blades; a heating and cooling system comprises an air compressor, a gas control unit, a flame heating nozzle and a cooler nozzle, the air compressor is connected with the gas control unit, the gas control unit is communicated with the flame heating nozzle and the cooler nozzle through pipelines, the flame heating nozzle is arranged on the outer side of the wheel disc, and the cooler nozzle is arranged on the outer side of a feeding system; a data acquisition and control system is connected with a temperature and image acquisition device, and the temperature and image acquisition device is arranged on the outer side of the wheel disc; the feeding system is connected with the stepping motor, and a coating sample is arranged on the other side of the wheel disc. The test result provided by the invention can provide a reliable test basis for evaluation of the service performance of the sealing coating and research on high-speed friction wear behaviors and mechanisms.

Owner:HUANENG POWER INT INC +1

Composite connector for memory cards

InactiveCN101577381BEasy to assembleSimple and reliable installationCoupling device connectionsSensing record carriersMemory cards

The invention provides a composite connector which reduces occupied portion of a substrate caused by a plurality of memory cards related to the carried substrate. The composite connector of the invention has at least a card insertion opening where a first and a second memory card (24, 25) can be plugged on a body (21). The body (21) has a first body (27) for connection and a second body (28) for connection connected with an edge of the first body (27) for connection. On the first body (27) for connection, a first card conductive cover (22) is covered by way of forming a first card insertion opening (45) and on the second body (28) for connection, a second card conductive cover (23) is covered by way of forming a second card insertion opening (53). Outer side surface of the first card conductive cover (22) is used as a slide surface of the second memory card (25) so that the slide surface faces the second card insertion opening (53).

Owner:SMK CO LTD

Reluctance Electromagnetic Active Vibration Isolator

ActiveCN106337893BSave horizontal spaceGreat active outputVibration dampersMagnetic springsNoise controlMagnetic reluctance

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

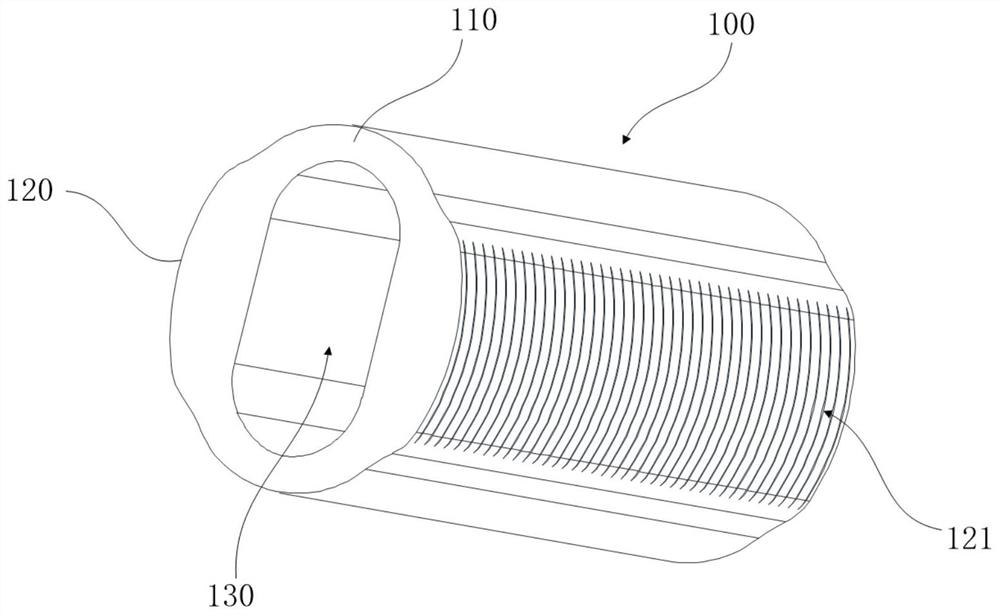

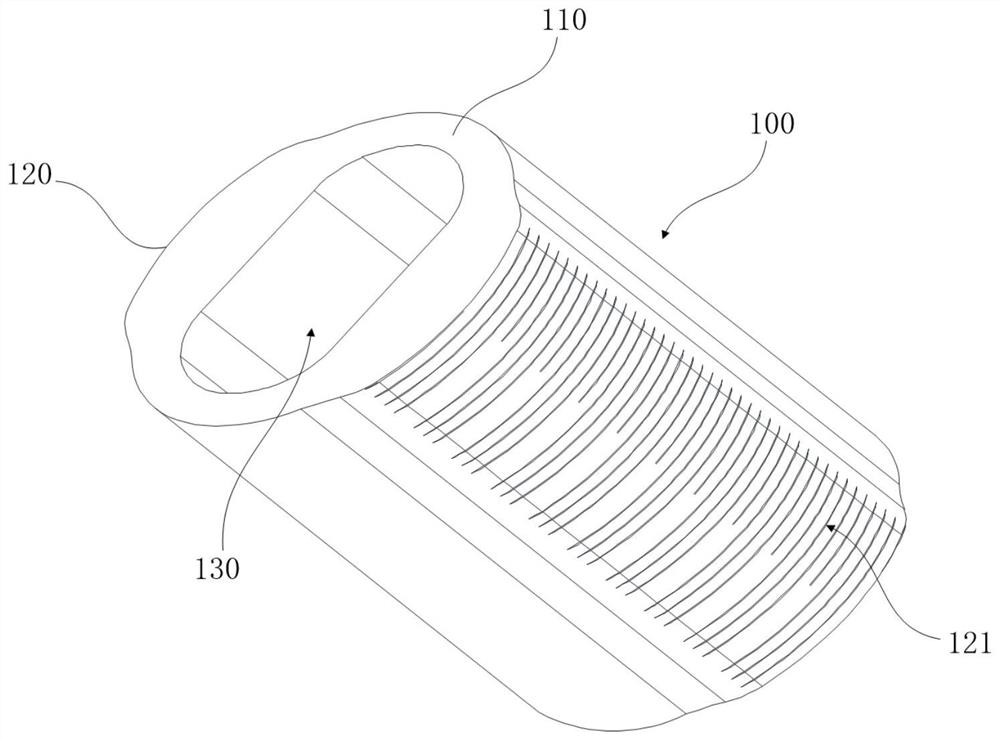

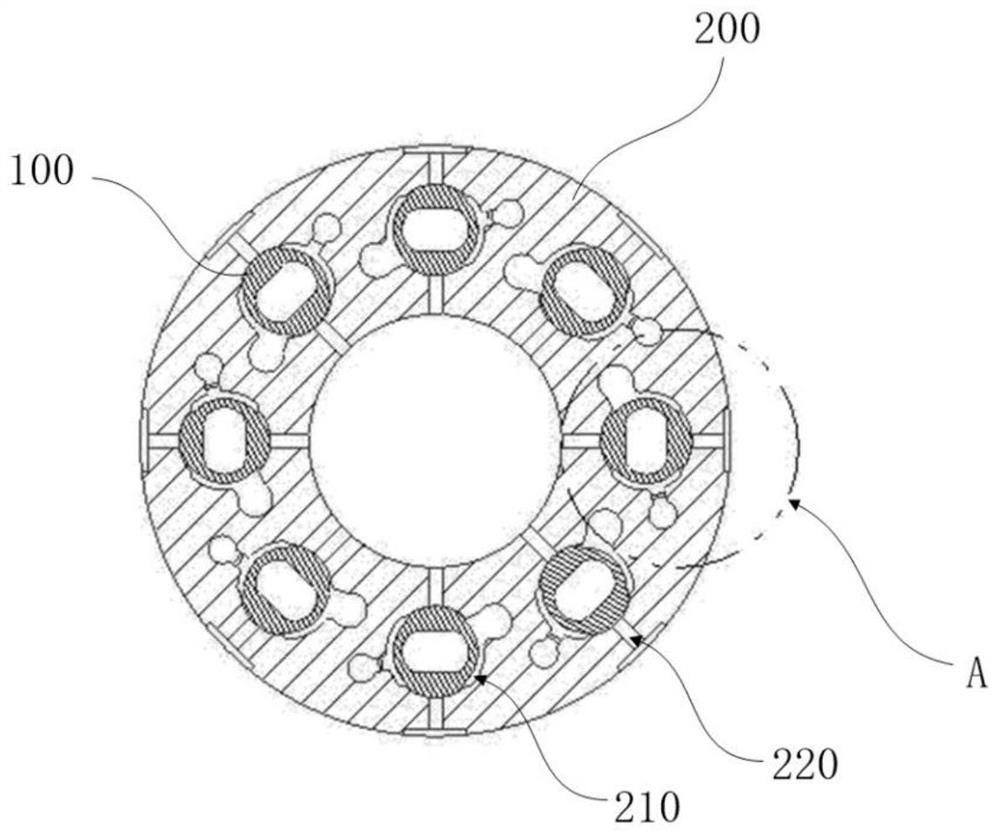

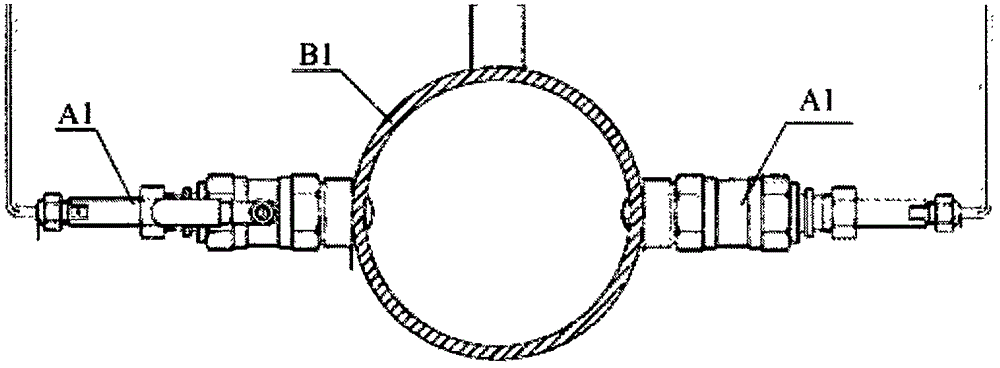

Expansion type rapid connecting piece for circular tube tracks, circular tubes and working method

PendingCN110725838AImprove reliabilityEasy constructionRod connectionsManipulatorStructural engineeringMechanical engineering

The invention provides an expansion type rapid connecting piece for circular tube tracks, circular tubes and a working method. The expansion type rapid connecting piece for the circular tube tracks comprises a cylindrical connecting piece body, an external diameter of the connecting piece body is in clearance fit with internal diameters of the circular tubes, at least one counter bore is correspondingly formed in the positions, close to the two ends, of the top of the connecting piece body, wire sleeves coaxial with the counter bores are arranged at the top of the inner side of the connectingpiece body, and a bolt fixing structure arranged opposite to the wire sleeves is arranged at the bottom of the inner side of the connecting piece body; gaps extending to the inside from the end partsare correspondingly formed in the two sides of the bottoms of the two ends of the connecting piece body, transformation parts are correspondingly formed at the bottoms of the two ends of the connecting piece body, and the bolt fixing structure is arranged on the transformation parts; and when the two circular tube tracks are connected, expansion force generated from the interiors of the two circular tube tracks connects and fastens the two circular tubes, operation construction in a tunnel is greatly convenient for construction personnel, and the reliability of the circular tube tracks after connection is high.

Owner:康威通信技术股份有限公司

Reluctance Electromagnetic Active Vibration Absorber

ActiveCN106286666BOverall small sizeStrong engineering applicabilityVibration dampersMagnetic springsNoise controlVibration control

The invention belongs to the technical field of vibration noise control and particularly relates to an active vibration absorber. The magnetic resistance type electromagnetic active vibration absorber comprises a vibration absorber lower installation plate, a vibration absorber cover, a vibration absorber upper installation plate, a rotor assembly and a stator assembly. Four rolling guide rail pairs are installed between the rotor assembly and the stator assembly. The rotor assembly is connected with the vibration absorber lower installation plate and the vibration absorber upper installation plate through springs. The rotor assembly can freely vibrate through the rolling guide rail pairs. The magnetic resistance type electromagnetic active vibration absorber can be installed and used in combination with various types of passive vibration absorbers and can be arranged on a controlled object or a base at will, after a coil is electrified with alternating current, electromagnetic force is generated between the rotor assembly and the stator assembly, the stator coil generates Lorentz force, the resultant force of the electromagnetic force and the Lorentz force drives a vibration absorber rotor to move, the vibration absorption force generated by the vibration absorber rotor is used for offsetting the vibration of the controlled object, and the purpose of controlling vibration is achieved.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com