Self-lubricating friction-reducing sliding bed plate

A technology of self-lubricating and sliding bed boards, which is applied in roads, rails, buildings, etc., can solve the problems of increased processing workload and manufacturing costs, increased labor load of public workers, complex sliding bed structure, etc., and achieves simple and reliable installation methods. Reduced daily maintenance workload and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

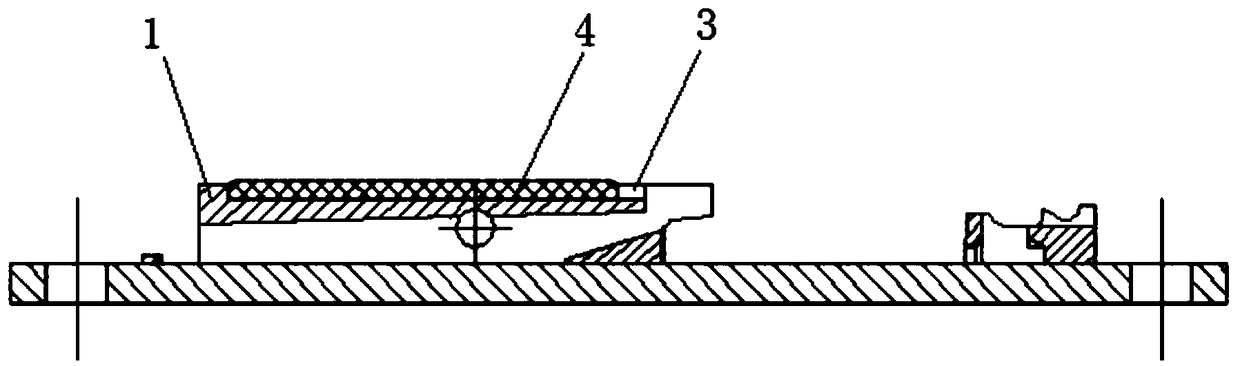

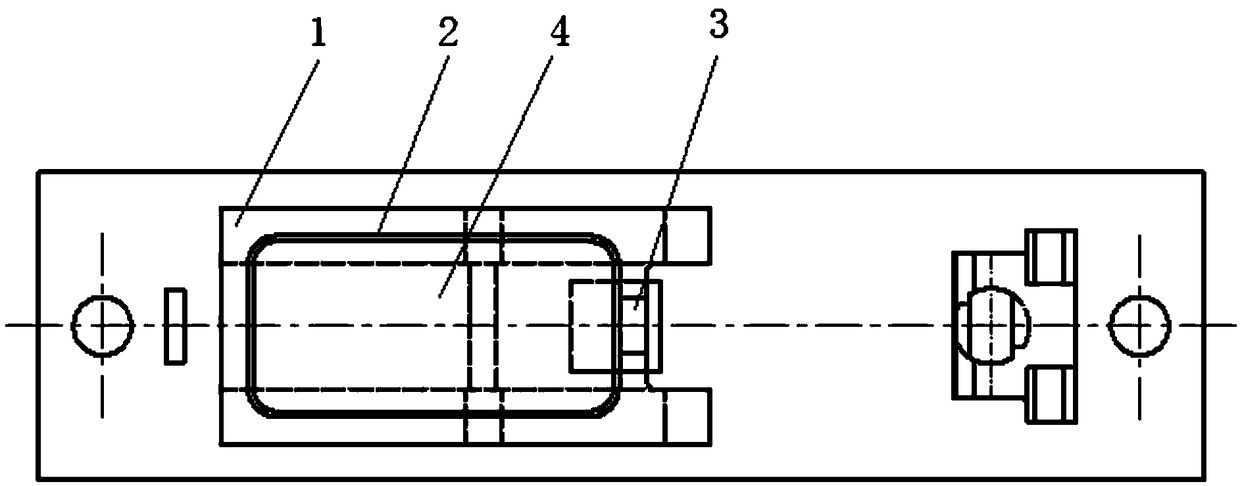

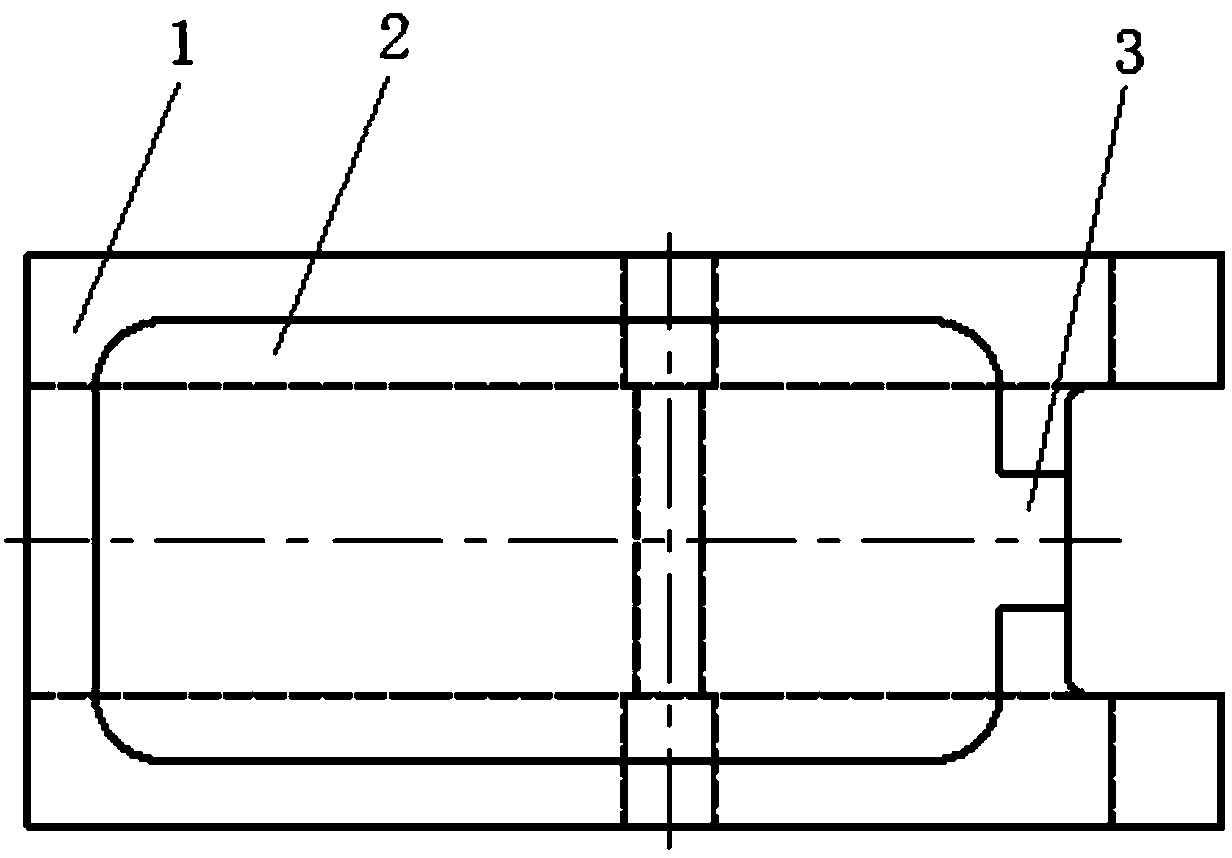

[0014] Attached below figure 1 , 2 , 3 and the specific embodiment describe the present invention in detail.

[0015] A self-lubricating anti-friction sliding bed plate, the upper end surface of the sliding bed platform (1) of the sliding bed plate is formed with a square groove (2), and a wear-resistant self-lubricating plate (4) is embedded in the square groove (2) , the front, rear, left, right, and lower directions of the wear-resistant self-lubricating plate (4) are positioned through the square groove (2), and the upper surface of the wear-resistant self-lubricating plate (4) protrudes from the sliding bed (1) 2-3mm on the upper end surface; the square groove (2) is a rectangular groove, and one side of the rectangular groove is provided with a gap (3), and the wear-resistant self-lubricating plate (4) is a rectangular structure formed at one time, And the wear-resistant self-lubricating plate (4) and the square groove (2) are bonded together by an adhesive, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com